Semi-spherical dynamic pressure motor bearing gap measuring device and method

A dynamic pressure motor and bearing clearance technology, which is applied in the field of hemispherical dynamic pressure motor bearing clearance measuring devices, can solve the problems that the detection accuracy cannot meet the requirements of use, lack of measurement methods, and affect production efficiency, and achieves simple structure and high detection accuracy. , the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

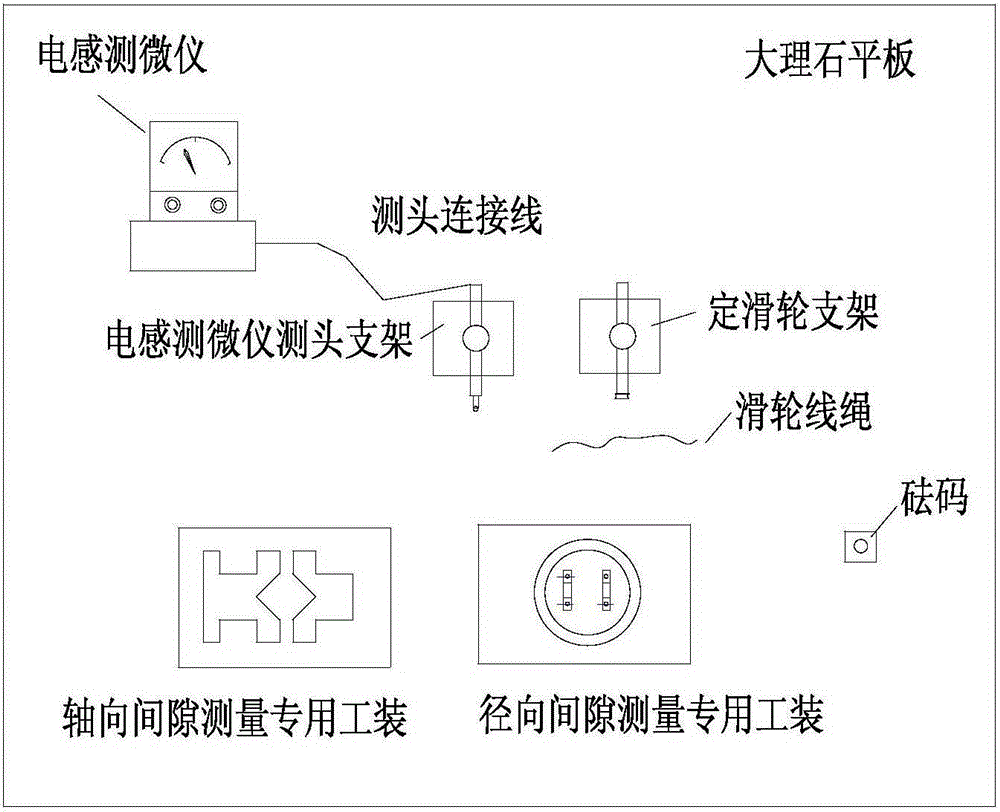

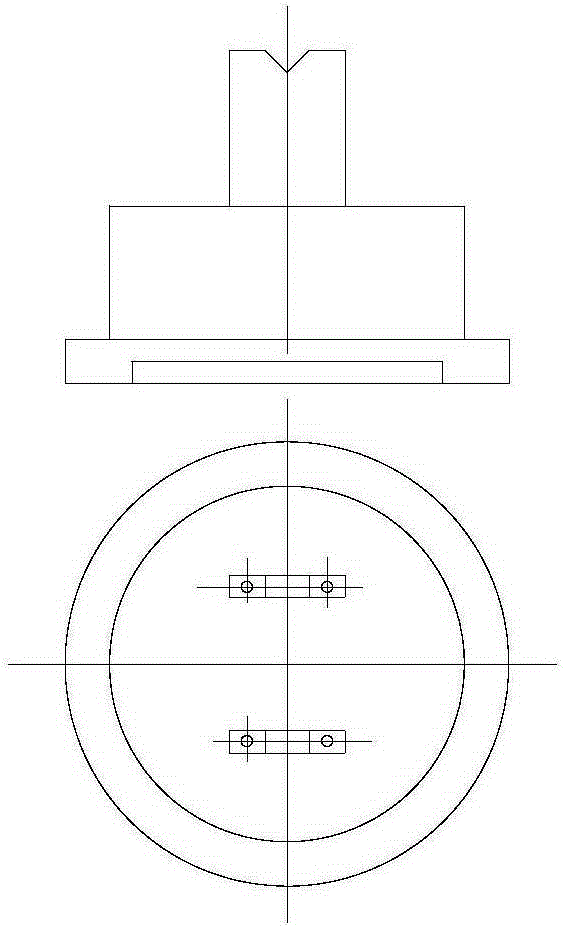

[0043] Such as figure 1 As shown, the hemispherical dynamic pressure motor bearing gap measurement device includes an inductance micrometer, a marble plate, an axial gap measurement tool, a radial gap measurement tool, a probe connection line, a pulley cable, a fixed pulley, a fixed pulley bracket, Inductance micrometer probe bracket and weight; inductance micrometer with inductance micrometer probe;

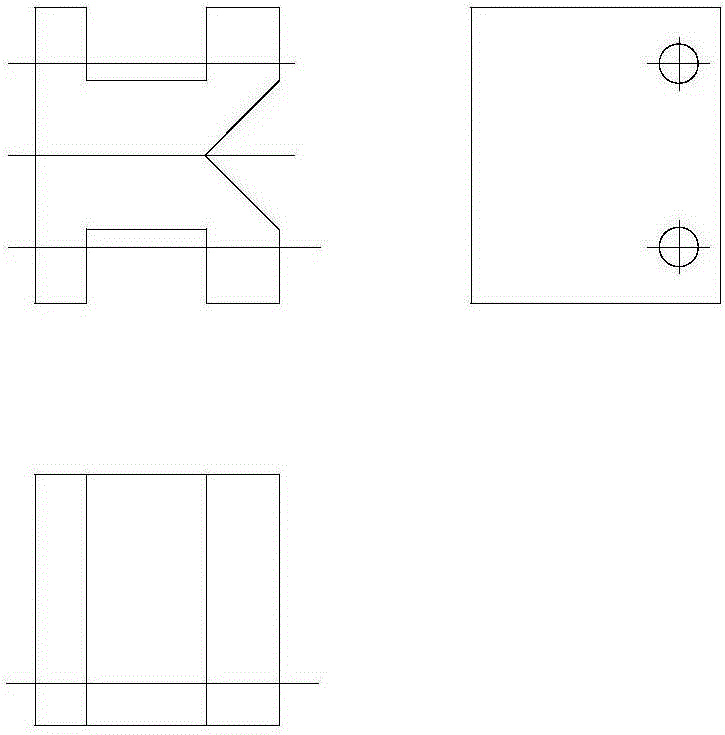

[0044] Axial gap measuring tooling includes the first V-shaped iron (such as figure 2 shown), the second V-shaped iron and two bolts, the axial clearance measuring tool is used to fix the outer circle of the rotor of the hemispherical dynamic pressure motor, the first V-shaped iron is an iron block with a V-shaped groove in the middle part of the right surface , the second V-shaped iron is an iron block with a V-shaped groove in the middle part of the left surface;

[0045] The large end of the V-shaped opening of the first V-shaped iron is opposite to the large end of the V-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com