Tile plastering machine

A technology of ceramic tiles and ash buckets, which is applied in the direction of construction and building construction, and can solve problems such as uneven application, time-consuming and labor-intensive, and prone to hollowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

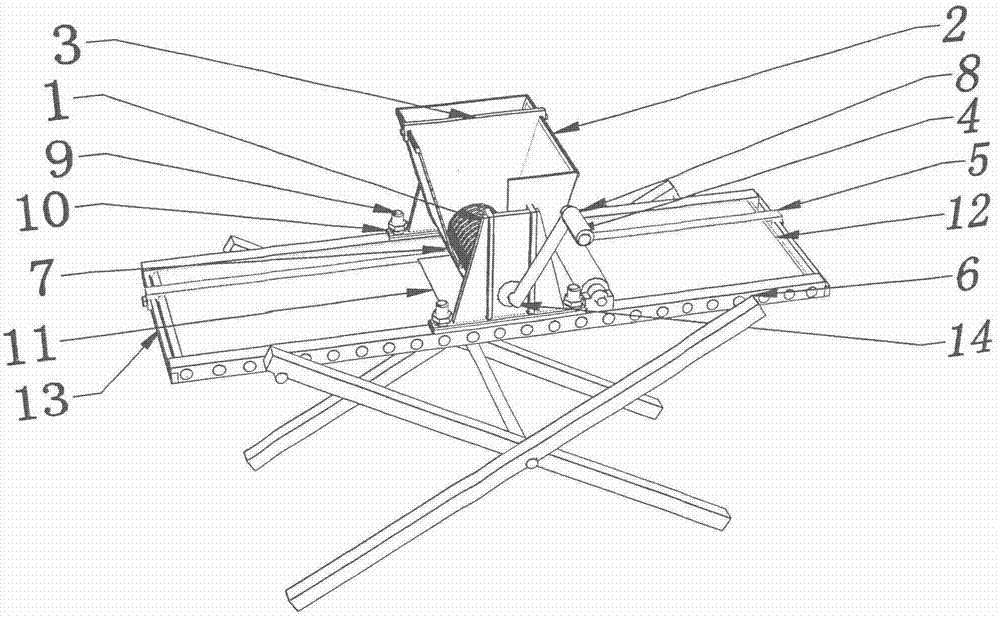

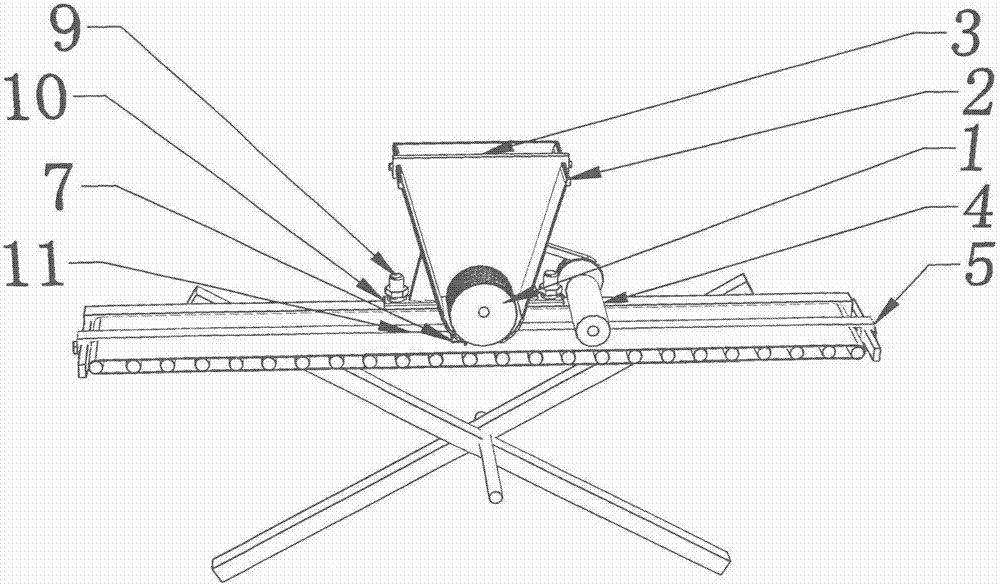

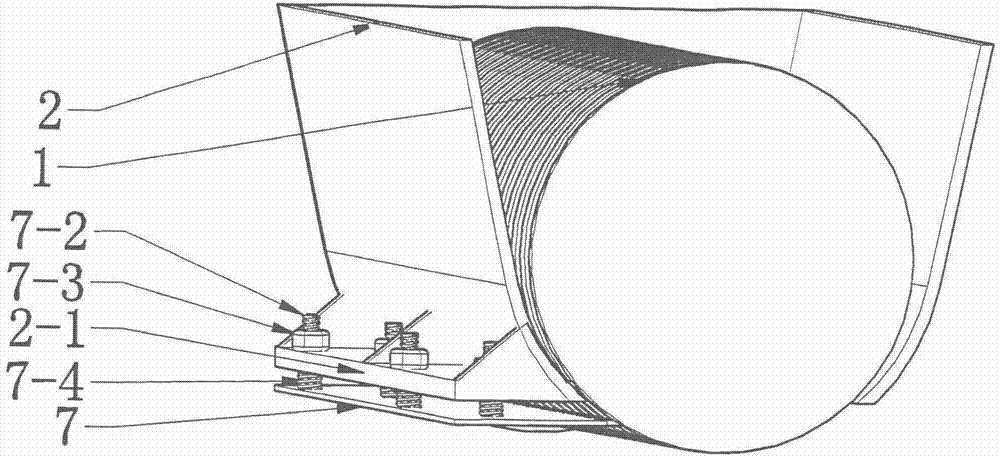

[0016] Embodiment 1: In order to facilitate the description of the implementation method of the present invention, this embodiment chooses a ceramic tile duster with comprehensive functions and introduces it in conjunction with the accompanying drawings. figure 1 It is a schematic diagram of the tile plastering machine, figure 2 It is a schematic diagram of the section of the tile plastering machine. In the figure: the ash hopper (2) is 302mm long, and the cross-section is divided into upper and lower parts. The upper part is trapezoidal in cross-section. The cross-section of the lower part is arc-shaped with upper and lower openings, the upper opening is larger and the lower opening is smaller, the radius of the arc is 60 mm, the upper opening is connected tangentially to the small opening of the trapezoid, and the upper opening of the ash hopper (2) is engraved with a width scale for easy determination The position of the partition, the ash bucket (2) is fixed on the ash bu...

Embodiment 2

[0017] Example 2: Figure 7 It is a schematic diagram of the structure of the electric plastering machine. The crank (8) of Example 1 is removed, and an electric motor is installed at an appropriate position under the conveyor belt (12), so that the shaft of the dust bucket is connected to the shaft of the electric motor (15) through a belt or a gear. , install a spring switch (16) near the ash hopper (2) on the inner side of a long frame (6) where the ceramic tile (11) of the ash hopper (2) enters the side tile conveying platform, to control the opening and closing of the motor, i.e. Into an electric plastering machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com