Anti-graffito leather finishing agent and using method thereof

A leather finishing agent, anti-graffiti technology, applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc., can solve the anti-graffiti protection of leather The problem of poor effect, etc., can restore the appearance effect, improve the protection effect, and reduce the effect of graffiti pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

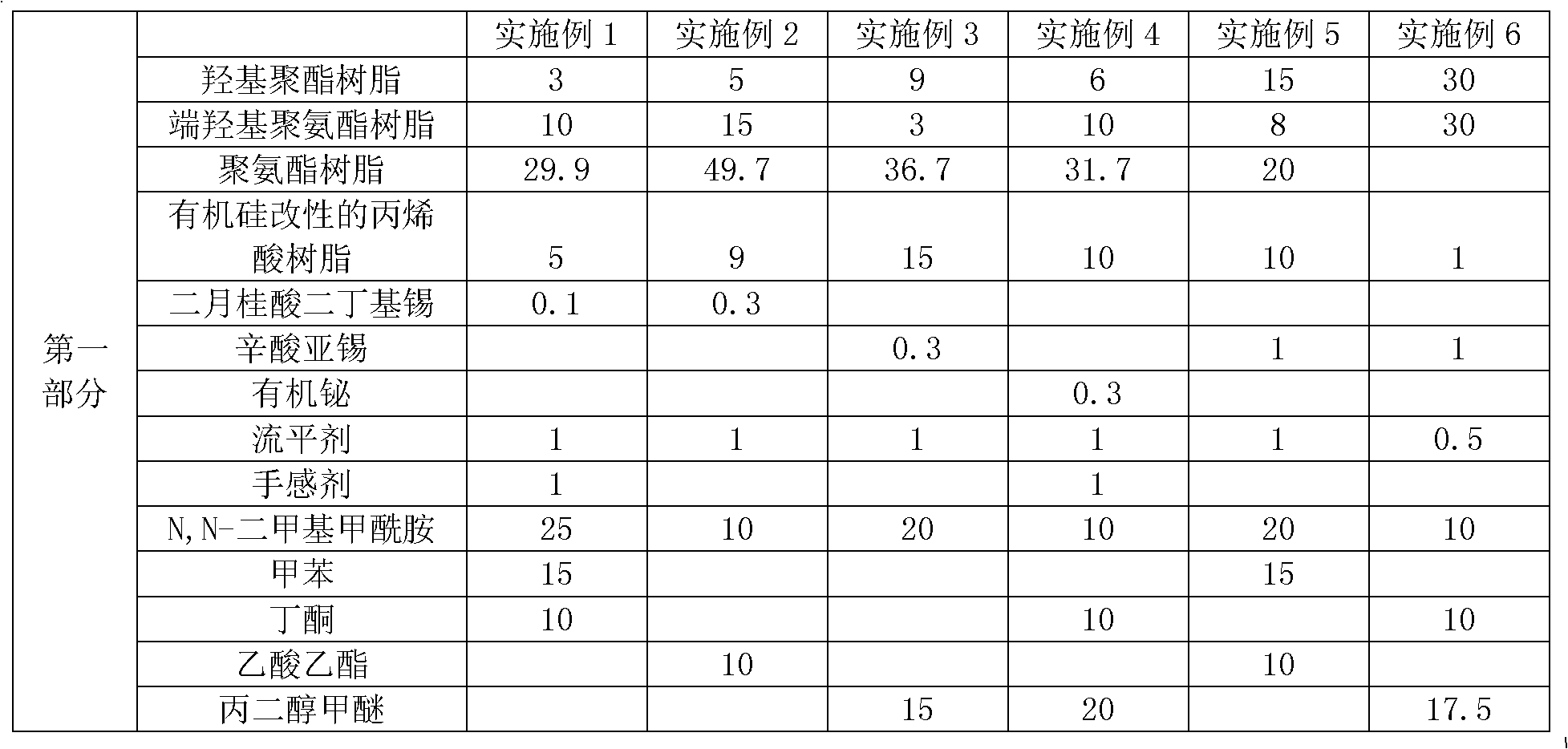

Embodiment 1

[0013] 5 parts of hydroxyl polyester resins, 8 parts of hydroxyl-terminated polyurethane resins, and 34.8 parts of polyurethane resins are added to the stirring tank, and then 25 parts of N, N-dimethylformamide, 10 parts of toluene and 10 parts of butanone are added, Stir for 30 minutes; then add 5 parts of silicone-modified acrylic resin, 0.2 parts of dibutyltin dilaurate, 1 part of leveling agent and 1 part of hand feeling agent while stirring, continue stirring for 20 minutes, and filter.

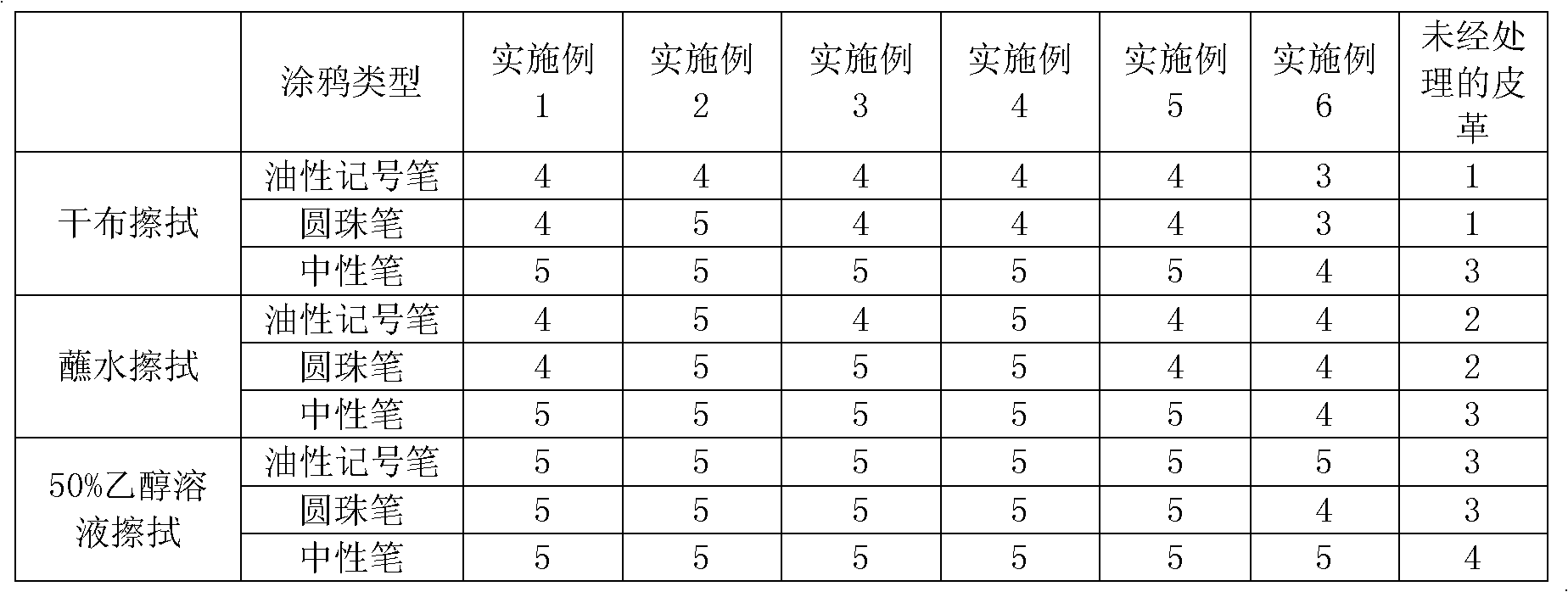

[0014] Mix 100 parts of the first part with 2.8 parts of HDI trimer, and then use the printed construction process to treat the surface of the synthetic leather, and bake it in an oven at 130 ° C for 3 minutes. Then test the anti-graffiti performance of the synthetic leather. The test method is to write on the surface of the anti-graffiti treated leather with an oily marker pen, a ballpoint pen and a neutral pen. After the graffiti marks are completely dry, use a dry cloth and a cloth str...

Embodiment 2

[0016] The distribution ratio of each component is according to the components of Example 2 listed in Table 1, and the first part is prepared according to the preparation method shown in Example 1. Mix 100 parts of the prepared first part with 3.5 parts of HDI biuret, then apply it to the surface of synthetic leather by roller coating, and bake it in an oven at 130°C for 3 minutes. Then test the anti-graffiti performance of synthetic leather, the method of testing is carried out according to the method for anti-graffiti performance test among the embodiment 1, test result is as shown in table 2. The results show that the anti-graffiti effect has reached level 4 or above.

Embodiment 3

[0018] The distribution ratio of each component is according to the components of Example 3 listed in Table 1, and the first part is prepared according to the preparation method shown in Example 1. Mix 100 parts of the prepared first part with 9.5 parts of blocked IPDI trimer, then apply it to the surface of synthetic leather by roller coating, and bake in an oven at 150°C for 4 minutes. Then test the anti-graffiti performance of synthetic leather, the method of testing is carried out according to the method for anti-graffiti performance test among the embodiment 1, test result is as shown in table 2. The results show that the anti-graffiti effect has reached level 4 or above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com