License plate wiping machine and license plate wiping method

A technology for erasing characters and license plates, applied in decorative arts, painting tools, etc., can solve the problems of solvent volatile environment, waste of cloth, pollution, etc., and achieve the effect of high wiping efficiency, preventing volatilization and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

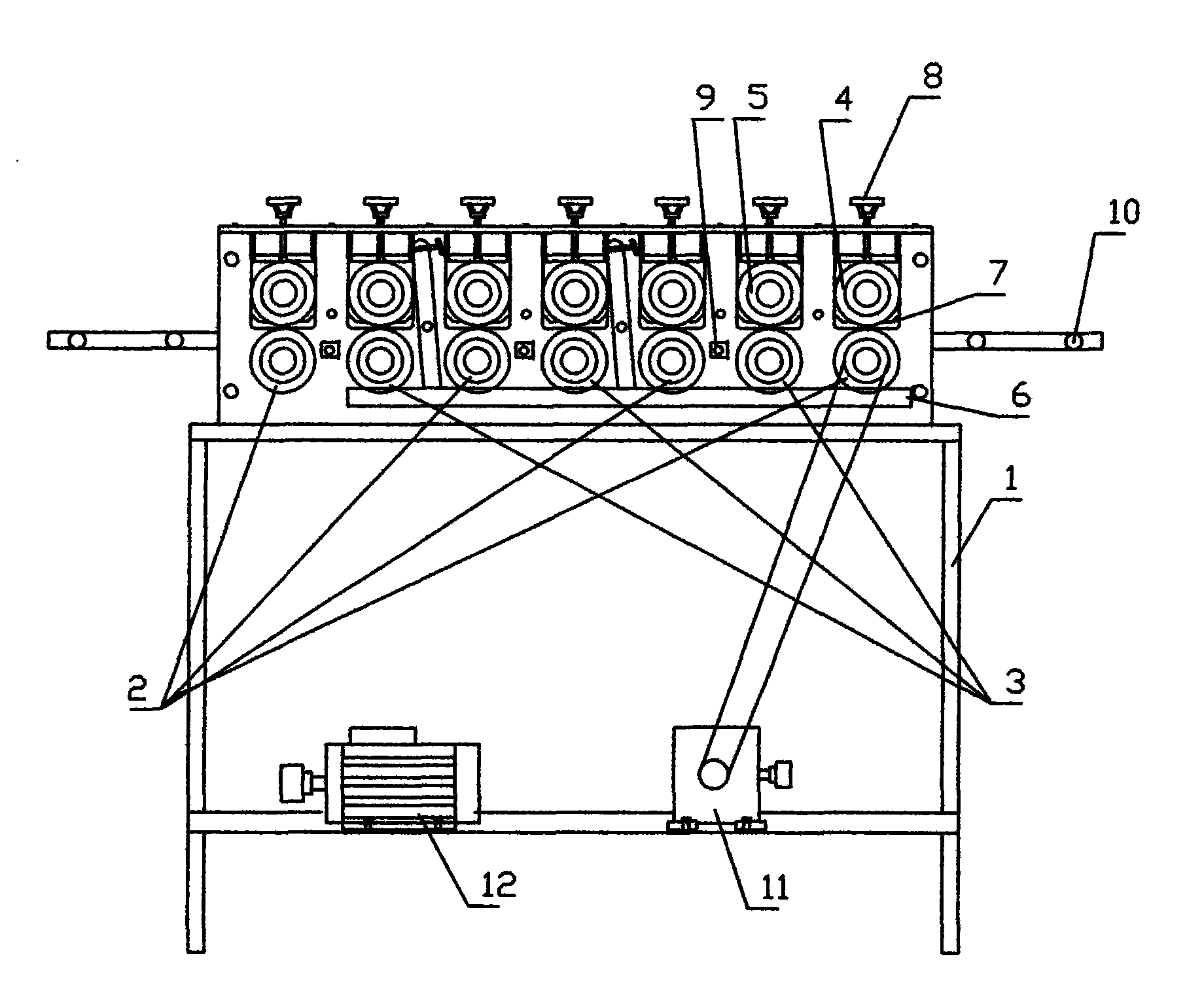

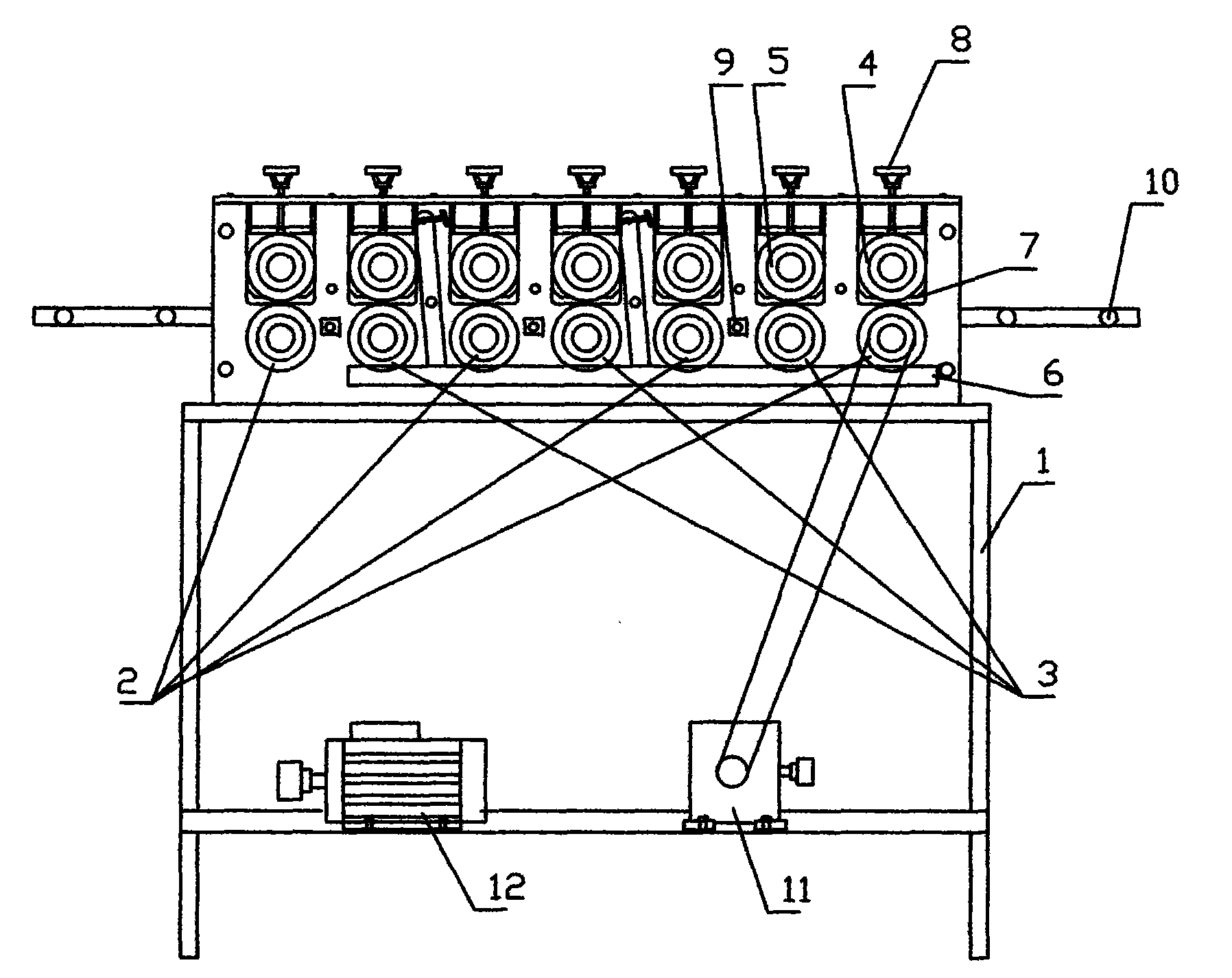

[0022] Example: such as figure 1 As shown, the license plate erasing machine includes a frame 1, a transmission rubber roller 2, and a friction rubber roller 3. The number of the transmission rubber rollers 2 is four, and they rotate counterclockwise. The quantity of the friction cots 3 is three, which are respectively arranged between every two adjacent transmission cots 2, and rotate clockwise, and the rotation speed is faster than the transmission cots. Each transmission cot roller is equipped with supporting pressure roller 4 respectively, and each friction cot roller 3 is respectively equipped with coordinating pressure roller 5, and described transmission cot roller, friction cot roller are placed on frame 1 in parallel with each other, and compression roller is installed on On the frame 1 , a part of the transmission rubber roller 2 and the friction rubber roller 3 is located in the solvent box 6 . The solvent box 6 is provided with a water level alarm.

[0023] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com