Method for manufacturing wiping rod

A manufacturing method and a technology for wiping sticks, which are applied in the directions of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor hot-melt effect at the adhesion point, easy to fall off, and unable to implement the action, etc. Improve the efficiency of wiping work, combine closely, and broaden the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

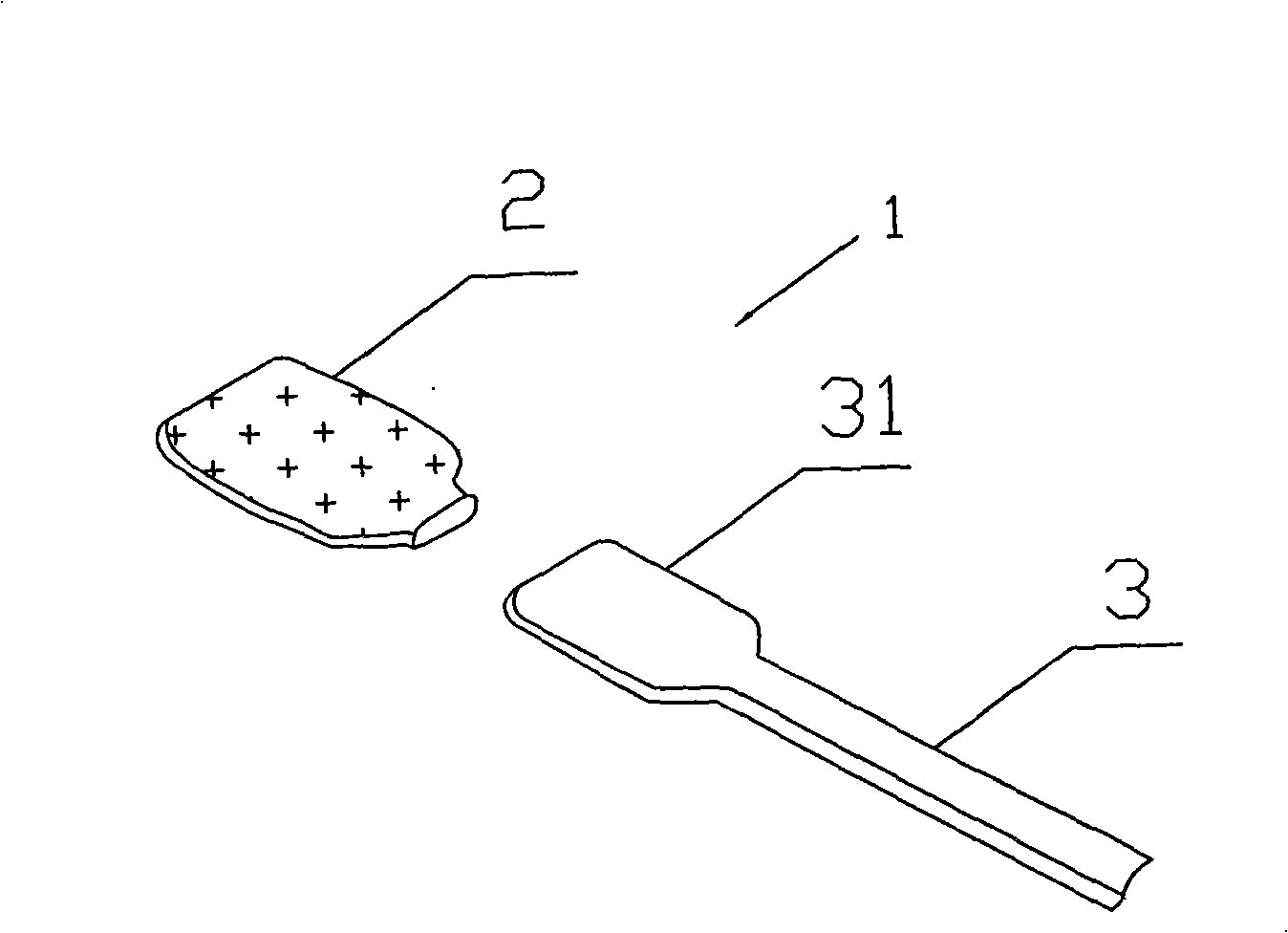

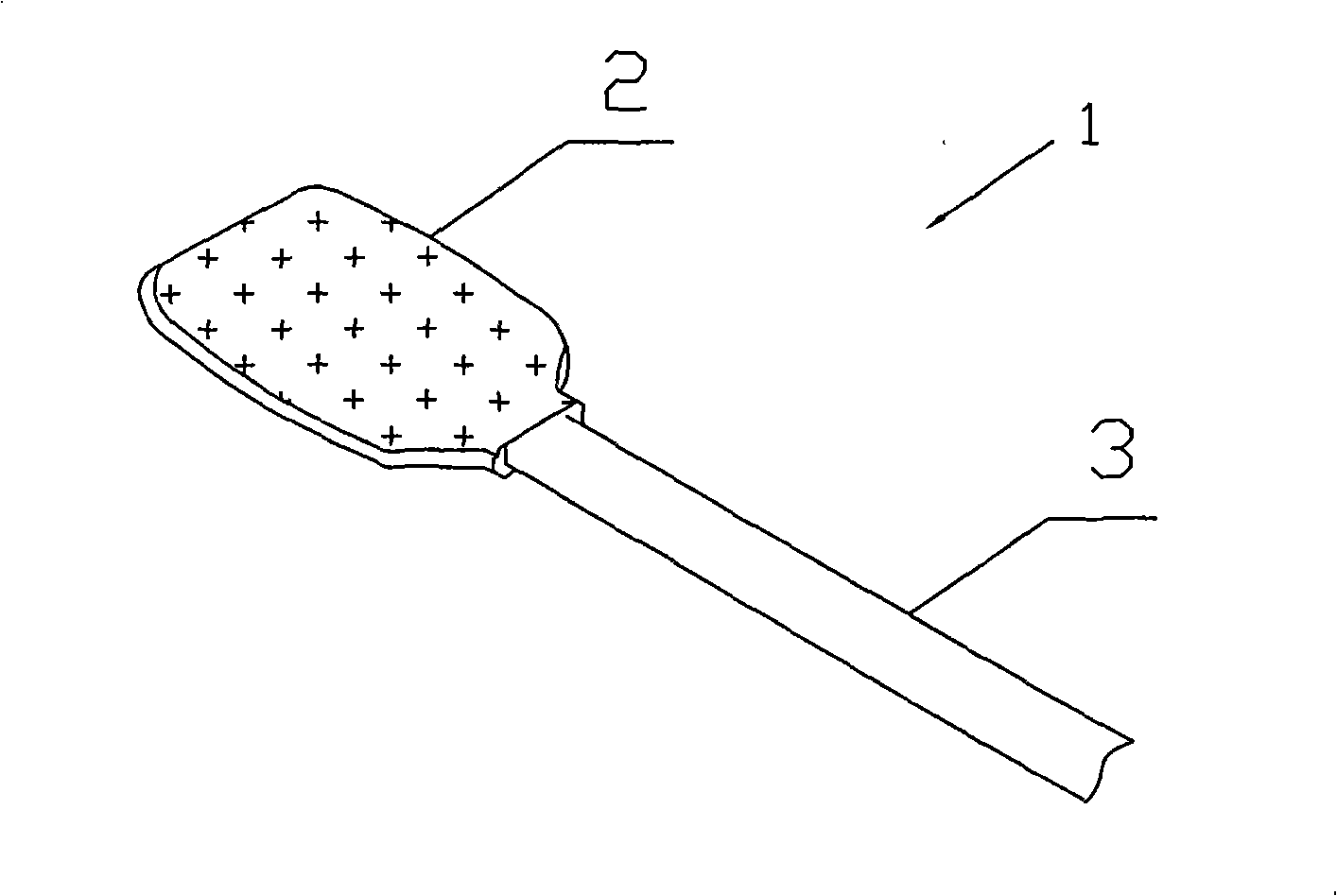

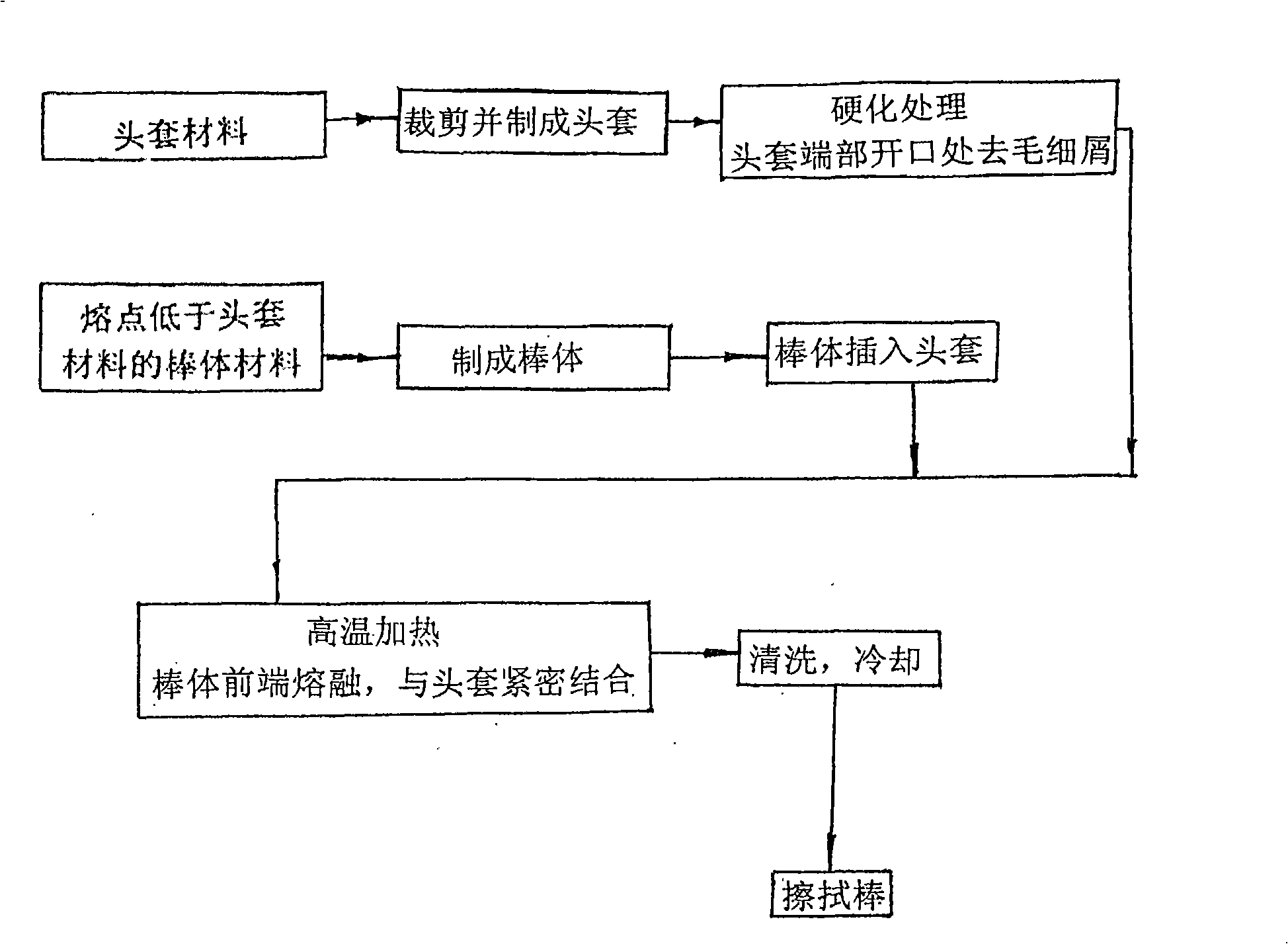

[0025] Embodiment 1 A kind of manufacturing method of wiping stick, such as figure 1 and figure 2 As shown, nylon cloth is used as the material of the head cover 2 , and polyethylene plastic, which has a melting point lower than that of the nylon cloth, is used as the material of the rod body 3 . The nylon cloth is cut and processed into the head cover 2 , and the material of the rod body 3 is made into the rod body 3 whose front end 31 is the same size as the head cover 2 . another example image 3 , Figure 4 and Figure 5 As shown, hardening heat treatment is performed on the port part of the head cover 2 (that is, the insertion part of the rod body 3). During the hardening process, the position heated by the hardening heat processor 41 is 2 mm away from the port of the head cover 2; the heating temperature is 250°C; the pressure is <0.3Mpa; the contact time is 1.5 seconds. The port part of the hardened headgear 2 has been converted from nylon cloth to nylon sheet, a...

Embodiment 2

[0026] In Example 2, basically the same procedure as in Example 1 was carried out. like figure 1 and figure 2 As shown, nylon cloth is used as the material of the head cover 2 , and polyethylene plastic, which has a melting point lower than that of the nylon cloth, is used as the material of the rod body 3 . The nylon cloth is cut and processed into the head cover 2 , and the material of the rod body 3 is made into the rod body 3 whose front end 31 is the same size as the head cover 2 . another example image 3 , Figure 4 and Image 6 As shown, hardening heat treatment is performed on the port part of the head cover 2 (that is, the insertion part of the rod body 3). During the hardening process, the position heated by the hardening heat processor 41 is 2 mm away from the port of the head cover 2; the heating temperature is 250°C; the pressure is <0.3Mpa; the contact time is 1.5 seconds. The port part of the hardened headgear 2 has been converted from nylon cloth to nyl...

Embodiment 3

[0027] In Example 3, basically the same procedure as in Example 1 was carried out. The sponge is used as the material of the head cover 2 , and the material with a melting point lower than that of the sponge, polyethylene plastic, is used as the material of the rod body 3 . The sponge is cut and processed into the head cover 2 , and the material of the rod body 3 is made into the rod body 3 whose front end 31 is the same size as the head cover 2 . another example image 3 , Figure 4 and Figure 5As shown, the port portion of the headgear 2 (ie, the insertion portion of the rod body 3 ) is subjected to a hardening heat treatment. During the hardening process, the hardening heat processor 41 is not in contact with the sponge head cover 2, but is in the form of radiant heating. The position heated by the hardening heat processor 41 is 4 mm away from the port of the headgear 2; the heating temperature is 200° C.; the pressure is <0.4 Mpa; the contact time is 2 seconds. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com