Rotatable magnetic glass wiper

A glass wiping and rotating magnet technology, applied in cleaning equipment, household appliances, applications, etc., can solve the problems of high safety hazards, laborious and low efficiency of magnetic glass wiping, and achieve reliable work, high wiping efficiency, and good cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

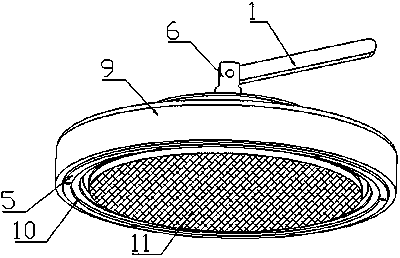

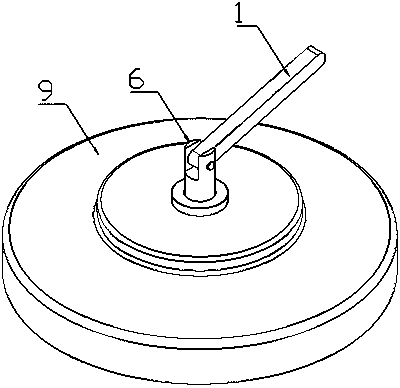

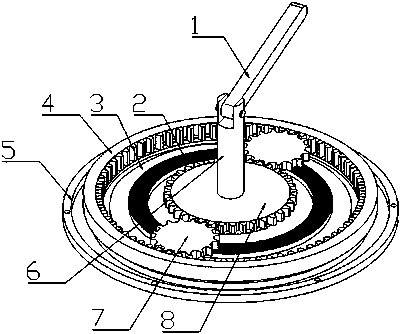

[0026] as attached Figures 1 to 6 shown

[0027] The invention provides a rotatable magnetic glass wiper, which includes a handle 1, a rotating magnet 2, a fixed disk 3, an inner gear ring 4, a fixed magnet 5, a rotating shaft 6, a planetary gear 7, a sun gear 8, a casing 9, and a slot 10 , wiping cloth 11 and bearing 12; the lower end of the casing 9 is provided with an annular draw-in groove 10, and the ring-shaped fixed magnet 5 is fixedly connected to the bottom surface of the draw-in groove 10 through screws, and the lower end surface of the fixed magnet 5 extends out of the draw-in groove 10. The rotating shaft 6 is installed on the upper end of the casing 9 through the bearing 12, the rotating shaft 6 protruding from the upper end of the casing 9 is hinged with a handle 1, and a sun gear 8 is fixedly connected to the rotating shaft 6 extending into the inside of the casing 9, and the lower end of the sun gear 8 is fixed A fixed disc 3 is connected, and an inner ring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com