Method for treating circulating water having wax oil leaked therein

A treatment method and technology for circulating water, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., and can solve the problems of expensive biological enzyme purifiers, etc. , to achieve the effect of high concentration ratio, low sewage discharge and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

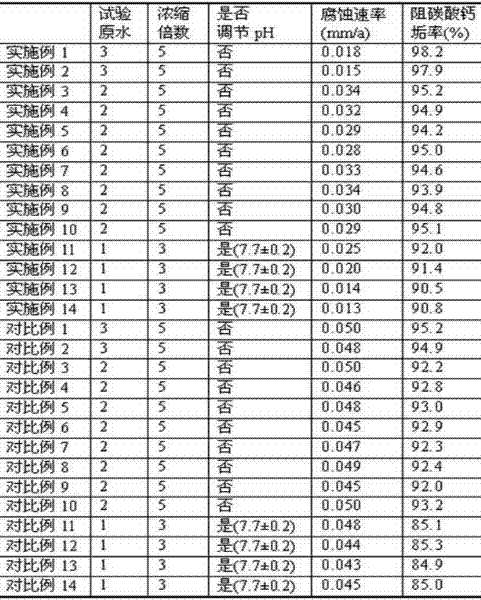

Embodiment 1

[0051] Preparation of scale and corrosion inhibitor: Dissolve 8.8g of zinc sulfate heptahydrate in 76g of water, dissolve evenly, add 8g of HEDP with a concentration of 50%, shake well, add 6.7g of acrylic acid with a solid content of 30% / 2- Methyl-2'-acrylamidopropanesulfonic acid copolymer (the mass ratio of acrylic acid to 2-methyl-2'-acrylamidopropanesulfonic acid in the copolymer is 7:3, and the limiting viscosity at 30°C is 0.068 dl / g), shake well, add 0.5g benzotriazole, shake well.

[0052] When the prepared scale and corrosion inhibitor solution is added to the test water (prepared from raw water 3) at a concentration of 100mg / L, the water HEDP, acrylic acid / 2-methyl-2'-acrylamide propane sulfonic acid copolymer, Zn 2+ The effective concentrations of benzotriazole and benzotriazole are 4mg / L, 2mg / L, 2mg / L and 0.5mg / L respectively.

[0053] Apply 200mg of wax oil on the surface of the test piece during the corrosion inhibition test, and 50mg of wax oil on the inner w...

Embodiment 2

[0055] Preparation of scale and corrosion inhibitors: Dissolve 10g of HPAA with a concentration of 40% and 8g of PBTCA with a concentration of 50% in 46.5g of water, dissolve evenly, add 8.8g of zinc sulfate heptahydrate, shake well, add 26.7g of solid content 30% acrylic acid / 2-methyl-2'-acrylamidopropanesulfonic acid copolymer (the mass ratio of acrylic acid to 2-methyl-2'-acrylamidopropanesulfonic acid in the copolymer is 7:3, The limiting viscosity at 30°C is 0.071dl / g), shake well.

[0056] When the prepared scale and corrosion inhibitor solution is added to the test water (prepared from raw water 3) at a concentration of 100 mg / L, HPAA, PBTCA, acrylic acid / 2-methyl-2'- Acrylamido propane sulfonic acid copolymer, Zn 2+ The effective concentrations are 4mg / L, 4mg / L, 8mg / L, 2mg / L respectively.

[0057] Apply 200mg of wax oil on the surface of the test piece during the corrosion inhibition test, and 50mg of wax oil on the inner wall of the volumetric flask during the scale...

Embodiment 3

[0059] Preparation of scale and corrosion inhibitors: add 20g of PBTCA with a concentration of 50% to 46.7g of water, shake well, add 33.3g of polyacrylic acid with a solid content of 30% (the limiting viscosity at 30°C is 0.069dl / g) , shake well.

[0060] When the prepared scale and corrosion inhibitor solution is added to the test water (prepared from raw water 2) at a concentration of 100mg / L, the effective concentrations of PBTCA and polyacrylic acid in the water are 10mg / L and 10mg respectively. / L.

[0061] Apply 200mg of wax oil on the surface of the test piece during the corrosion inhibition test, and 50mg of wax oil on the inner wall of the volumetric flask during the scale inhibition test, then add cetyltrimethylammonium chloride 30mg / L, op-10 30mg / L, test The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

| Ultimate viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com