Crystal cleaning process for improving quality of crystal finished product

A crystal and finished product technology, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of user loss, poor cleaning effect of sticky powder, difficult sticky powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

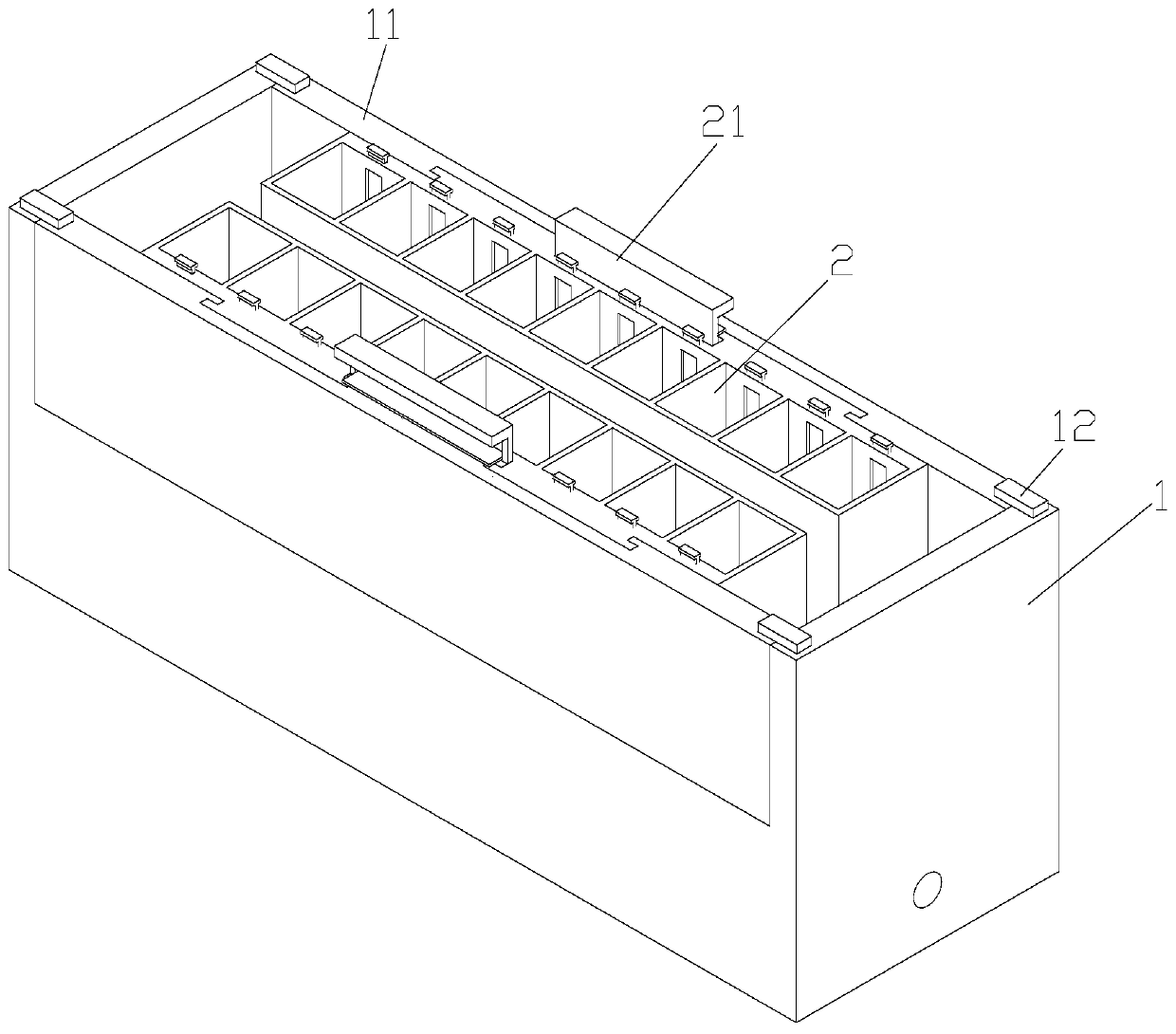

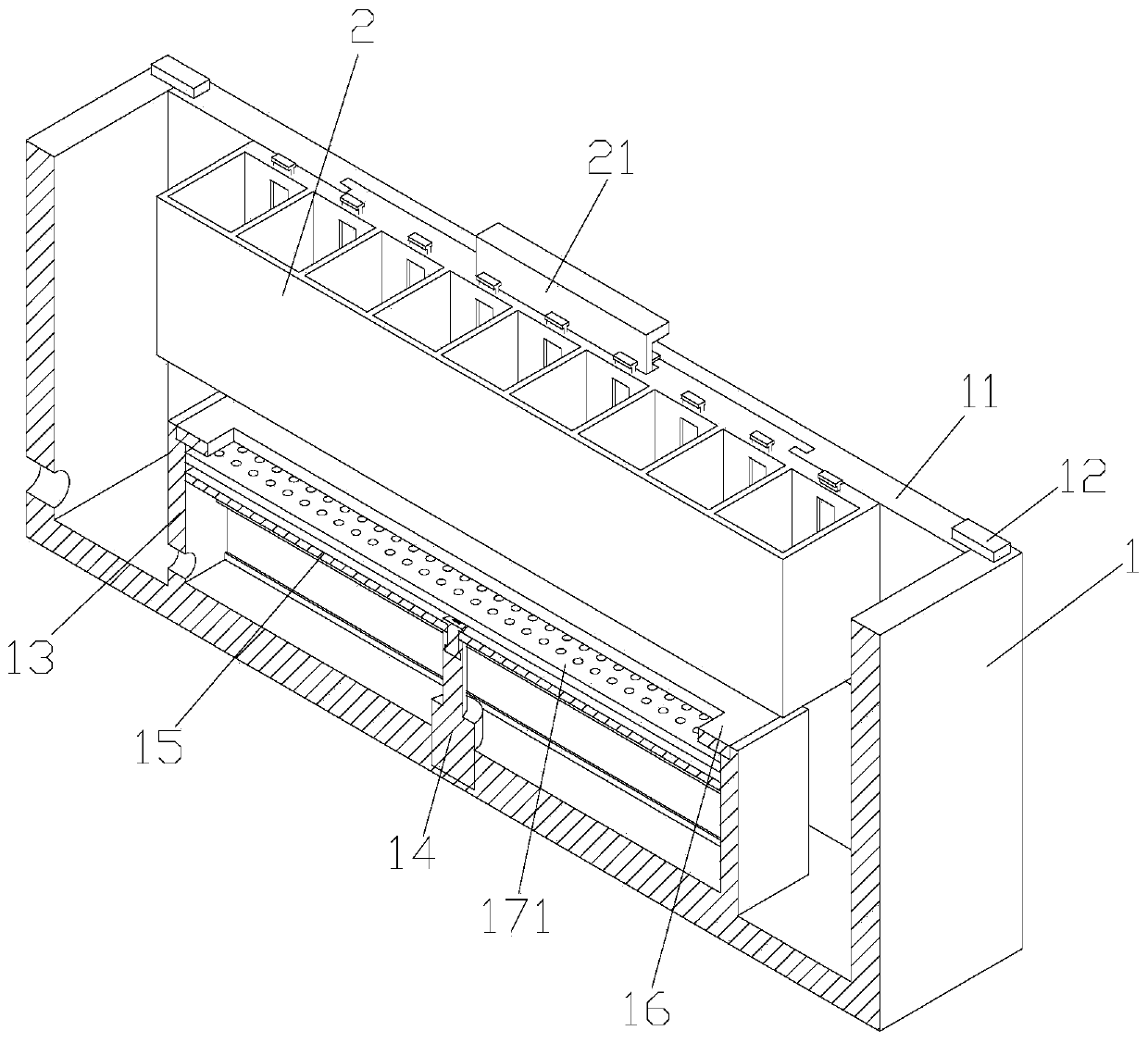

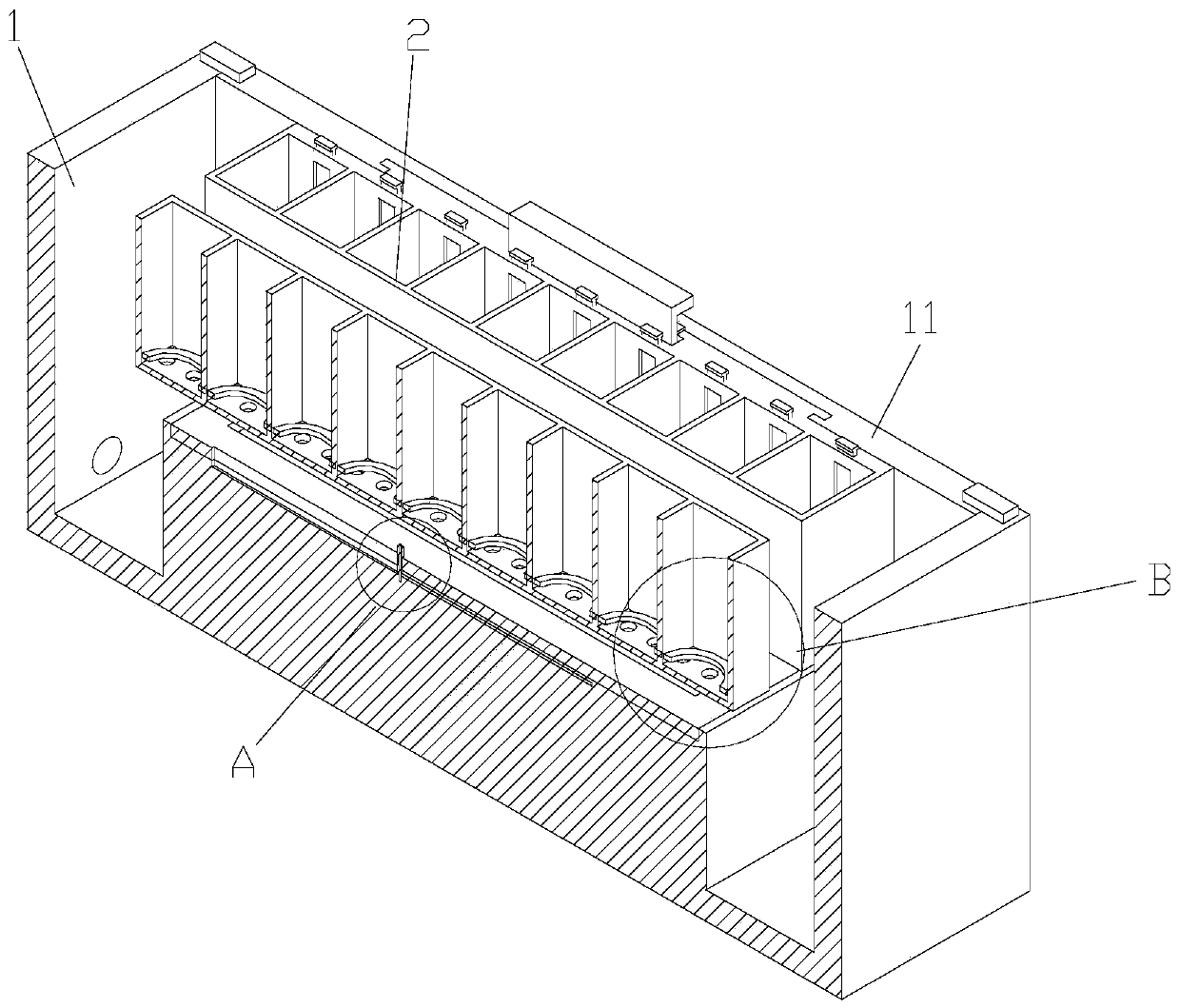

[0029]A crystal cleaning process to improve the quality of finished crystal products, including: a. Initial inspection: inspect the product to be cleaned, and place qualified products on the shelf to be cleaned; b. Soaking and reduction: place the product to be cleaned in water Carry out soaking and reduction; c. Soaking in liquid medicine: After the product is restored in water, add the liquid medicine into the water, and soak the product in liquid medicine to meet the cleaning requirements; d. Machine washing: Take out the product soaked in the liquid medicine, and wash the product Put it into the crystal cleaning equipment for cleaning operation; e, secondary cleaning: soak the cleaned product in clean water again to remove the syrup and dirt on the surface of the product; f, drying: put the clean product in Carry out drying treatment in the dryer; g, re-inspection: the product is tested again; the liquid medicine in the step c is a water-based cleaning agent, and the water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com