Sticky coal blending combustion bi-directional feeding device

A technology of two-way feeding and sticking of coal, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of unstable operation of the generator set, coal blocking, and high frequency of valve use, so as to achieve the function of diverting and blocking, and reduce the occupation. space, and the effect of reducing the probability of material blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

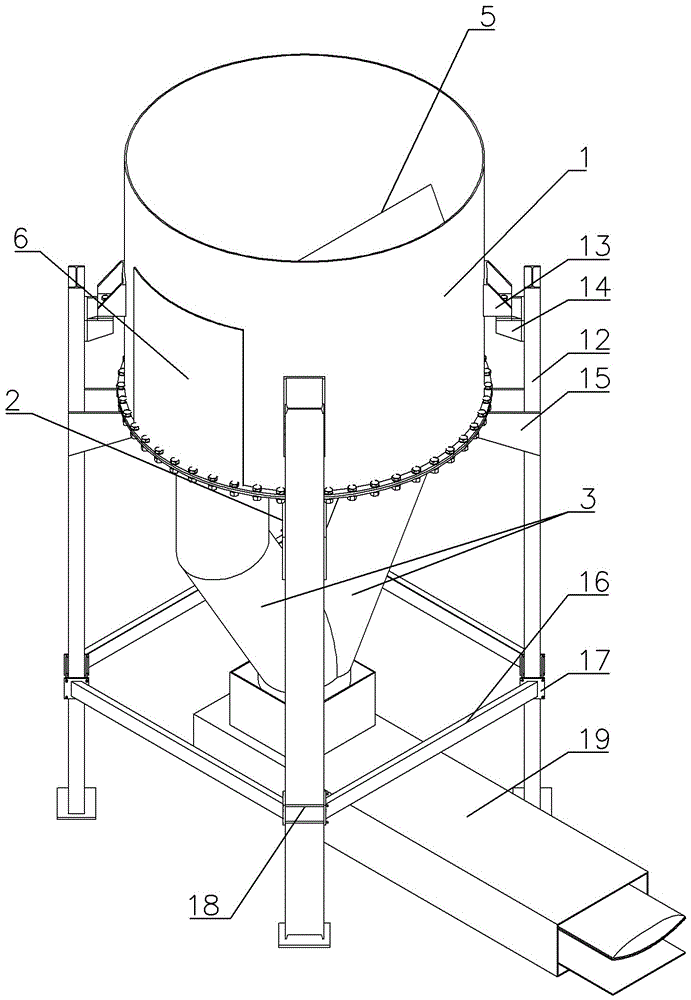

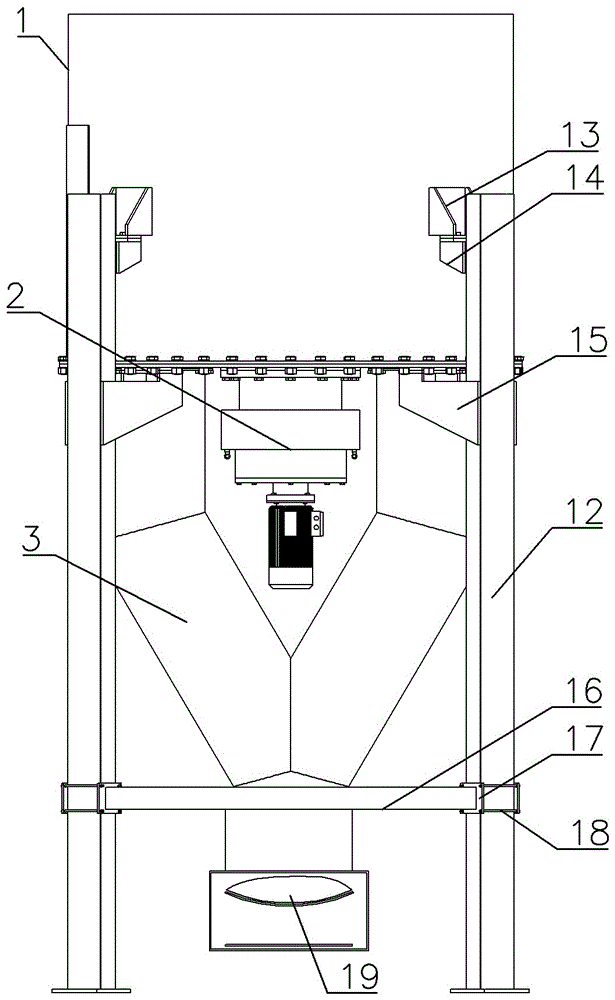

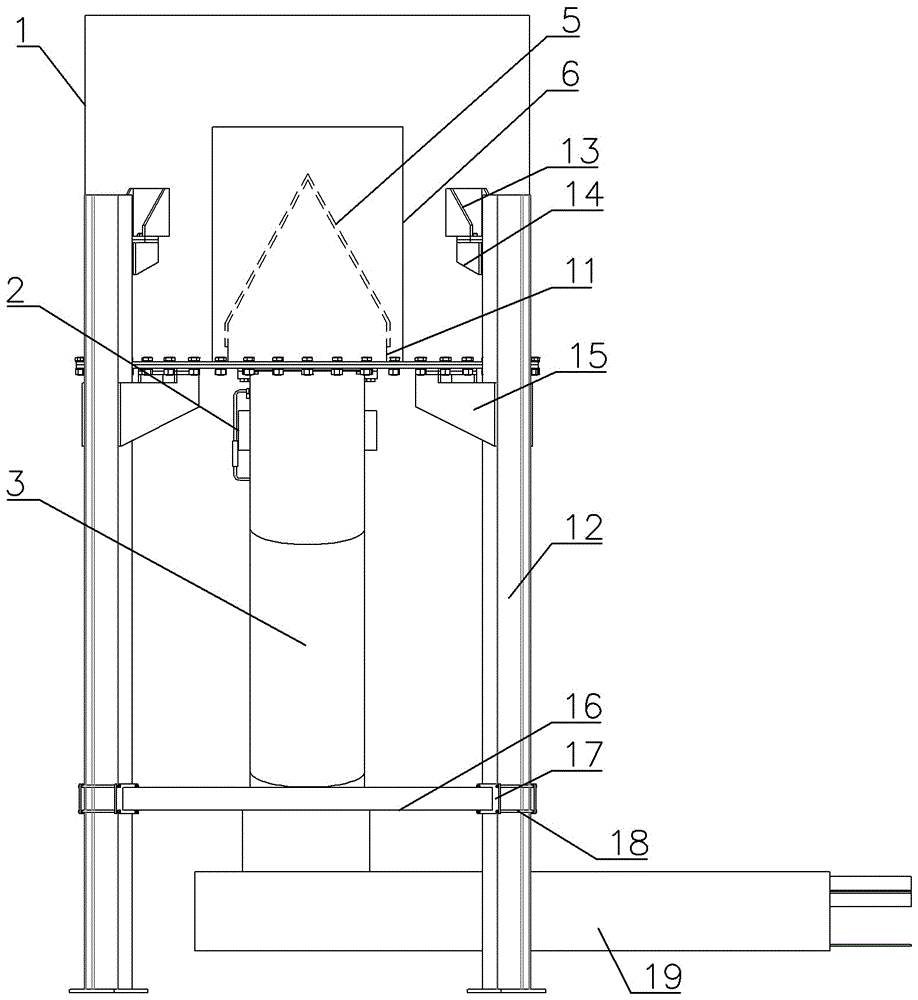

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Two-way feeding device for sticky coal mixed combustion, its structure is as follows Figure 1~4 As shown, it includes a coal bunker 1, a rotary cutting body, a power system 2 and a coal drop pipe 3.

[0028] The coal bunker 1 includes a side wall and a bottom plate made of NM400 wear-resistant material, and the side wall and the bottom plate of the coal bunker 1 are connected by a flange. Two discharge openings 4 are arranged symmetrically along the bottom plate axis of the coal bunker 1, and the lower part of each discharge opening 4 is connected with a coal drop pipe 3, and the coal drop pipe 3 includes a straight pipe section located below the discharge opening 4 and a The inclined pipe section connected below the straight pipe section, the lower ends of the inclined pipe section of the two coal falling pipes 3 are connected, the coal falling pipe 3 can n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com