Treatment method of circulating water with leaking oil

A treatment method and circulating water technology, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of expensive biological enzyme purifiers and achieve high concentration Multiples, simple operation, low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

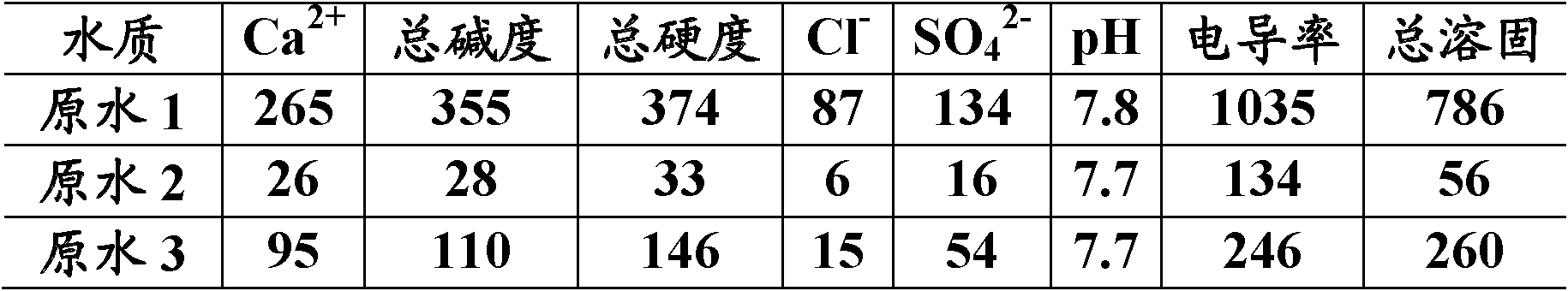

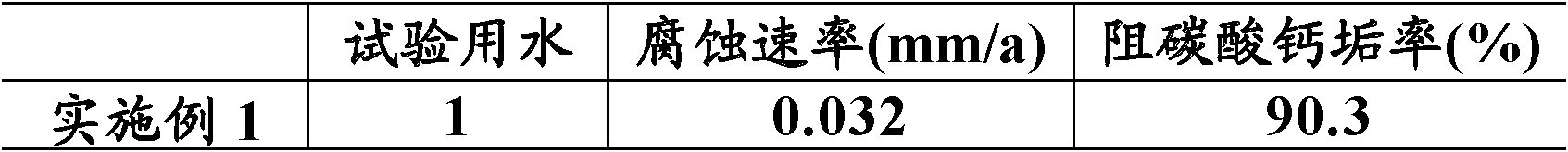

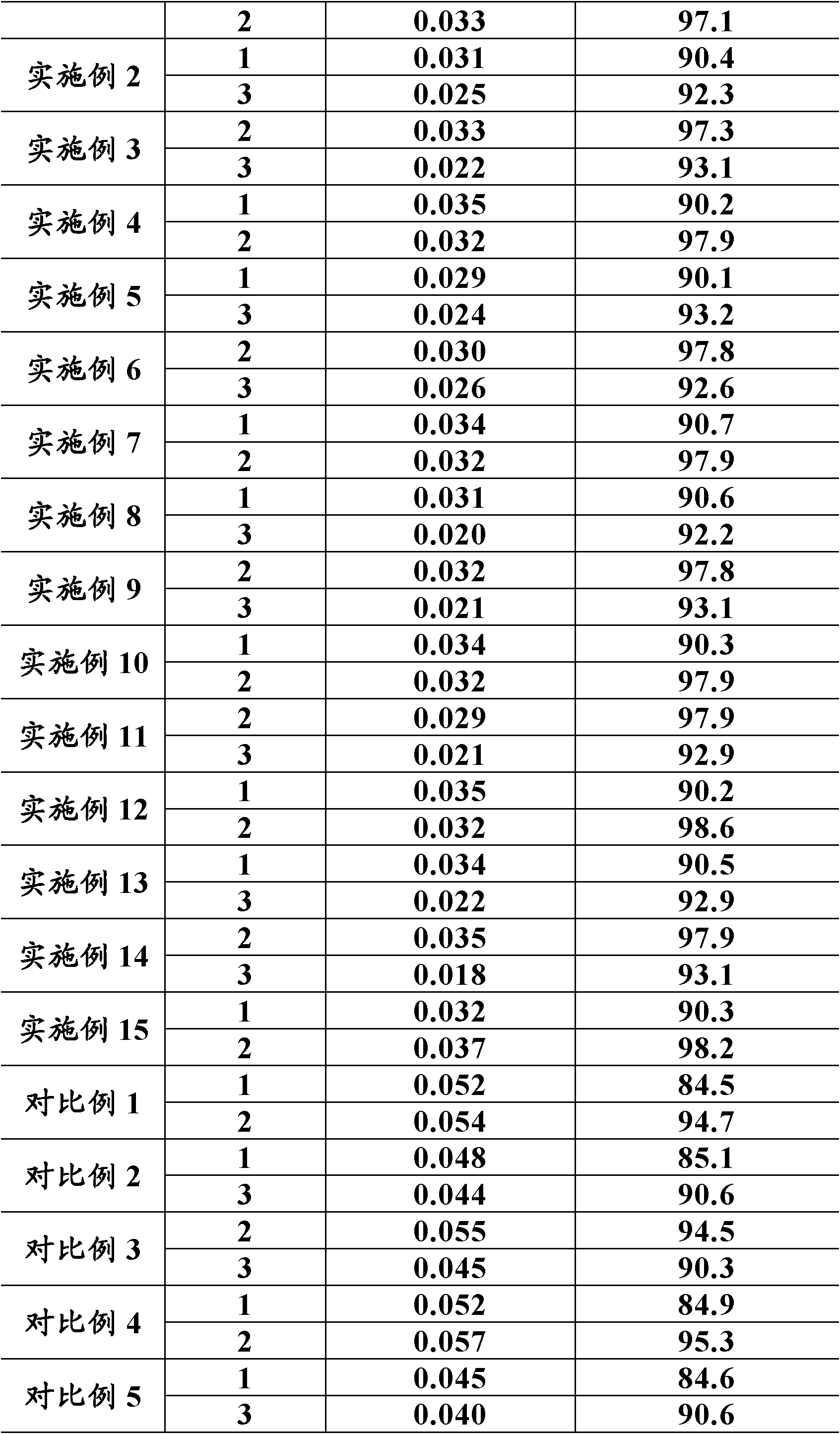

Embodiment 1

[0047] Preparation of scale and corrosion inhibitors: Weigh 147.4g sodium tetraborate decahydrate (containing B 4 o 7 2- 60.0 g) was added to 215.3 g of deionized water and stirred evenly, 24.0 g of hydroxyethylidene diphosphonic acid with an active ingredient of 50% was added, and acrylic acid / acrylic acid ester / 2-methyl-2'-propylene with a solid content of 30% was added Amidopropanesulfonic acid copolymer 13.3g (the mass ratio of acrylic acid, acrylate and 2-methyl-2'-acrylamidopropanesulfonic acid in the copolymer is 3:1:1, and the limiting viscosity number at 30°C is 0.065dl / g), with corrosion inhibitor 400.0g of the present invention. When the prepared scale and corrosion inhibitor solution is added to the test water 1 and 2 at a concentration of 400 mg / L, the decahydrate sodium tetraborate, hydroxyethylidene diphosphonic acid and acrylic acid / acrylic acid The effective concentrations of 2-methyl-2'-acrylamidopropanesulfonic acid copolymer are 60.0mg / L, 12.0mg / L and 4m...

Embodiment 2

[0050] Preparation of scale and corrosion inhibitors: Weigh 284.6g of anhydrous sodium metasilicate (containing SiO 2 140.0g) was added to 77.4g deionized water and stirred evenly, 8.0g of aminotrimethylene phosphonic acid with an active ingredient of 50% was added, and acrylic acid / maleic acid / 2-methyl-2'- Acrylamido propane sulfonic acid copolymer 16.7g (the mass ratio of acrylic acid, maleic acid and 2-methyl-2'-acrylamido propane sulfonic acid in the copolymer is 3: 1: 1, the limit viscosity at 30 ℃ number is 0.075dl / g), and acrylic acid / hydroxypropyl acrylate / methyl acrylate copolymer 13.3g (the mass ratio of acrylic acid, hydroxypropyl acrylate and methyl acrylate in the copolymer is 3: 1: 1, when 30 ℃ The limiting viscosity number is 0.068dl / g), is equipped with corrosion inhibitor 400.0g of the present invention. When the prepared scale and corrosion inhibitor solution is added to the test water 1 and 3 at a concentration of 400 mg / L, the anhydrous sodium metasilicate...

Embodiment 3

[0053] Preparation of scale and corrosion inhibitor: Weigh 95.0g of sodium gluconate and add it to 240.2g of deionized water and stir evenly, then add 16.0g of 2-phosphonic acid-1,2,4-tricarboxylic acid butyl with 50% active ingredient alkane, add 40.0 g of acrylic acid / acrylamide / 2-methyl-2'-acrylamidopropanesulfonic acid copolymer with a solid content of 30% (acrylic acid, acrylamide and 2-methyl-2'-acrylic acid in the copolymer The mass ratio of acrylamido propane sulfonic acid is 3: 1: 1, and the limiting viscosity number when 30 ℃ is 0.071dl / g), adds zinc sulfate heptahydrate 8.8g, stirs evenly, mixes corrosion inhibitor 400.0g of the present invention . When the prepared scale and corrosion inhibitor solution is added to the test water 2 and 3 at a concentration of 400 mg / L, the sodium gluconate and 2-phosphonic acid group-1,2,4-tri Butane carboxylate, acrylic acid / acrylamide / 2-methyl-2′-acrylamidopropanesulfonic acid copolymer and Zn 2+ The effective concentrations ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com