Automatic cleaning method of food processor

A food processing machine and automatic cleaning technology, which is applied in beverage preparation devices, household utensils, applications, etc., can solve the problems of poor cleaning effect and achieve the effect of improving the automatic cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the accompanying drawings.

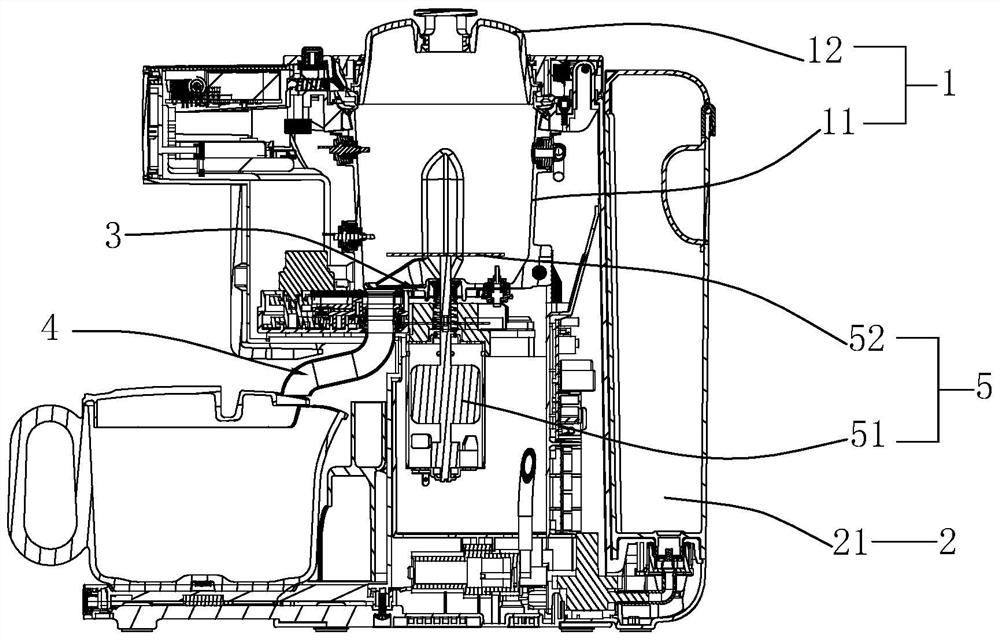

[0028] see figure 1 , is a schematic diagram of the structure of the food processor in the invention. The food processor includes a pulverizing cavity 1 and a water supply component 2 for supplying water to the pulverizing cavity 1. The pulverizing cavity 1 is provided with a pulverizing component 5, a heating component 3 and a slurry discharging component 4. The crushing chamber 1 is formed by the cooperation of the crushing cup 11 and the cup cover 12; the crushing part 5 includes the crushing blade 52 and the motor 51 located in the crushing cup 11, and the crushing blade 52 is installed on the main shaft of the motor 51; the water supply part 2 is the water tank 21 through the pipe The road communicates with the crushing chamber 1; the heating component 3 is a heating pipe arranged on the crushing cup 11;

[0029] The food processing machine automatically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com