Substrate transportation method and apparatus

一种基板搬送、基板的技术,应用在清洁方法和用具、运输和包装、化学仪器和方法等方向,能够解决复杂、去除异物、昂贵等问题,达到紧凑结构、可能性小、低廉结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now, the structure and operation of preferred embodiments of the substrate transfer method and apparatus according to the present invention will be described in detail with reference to the accompanying drawings.

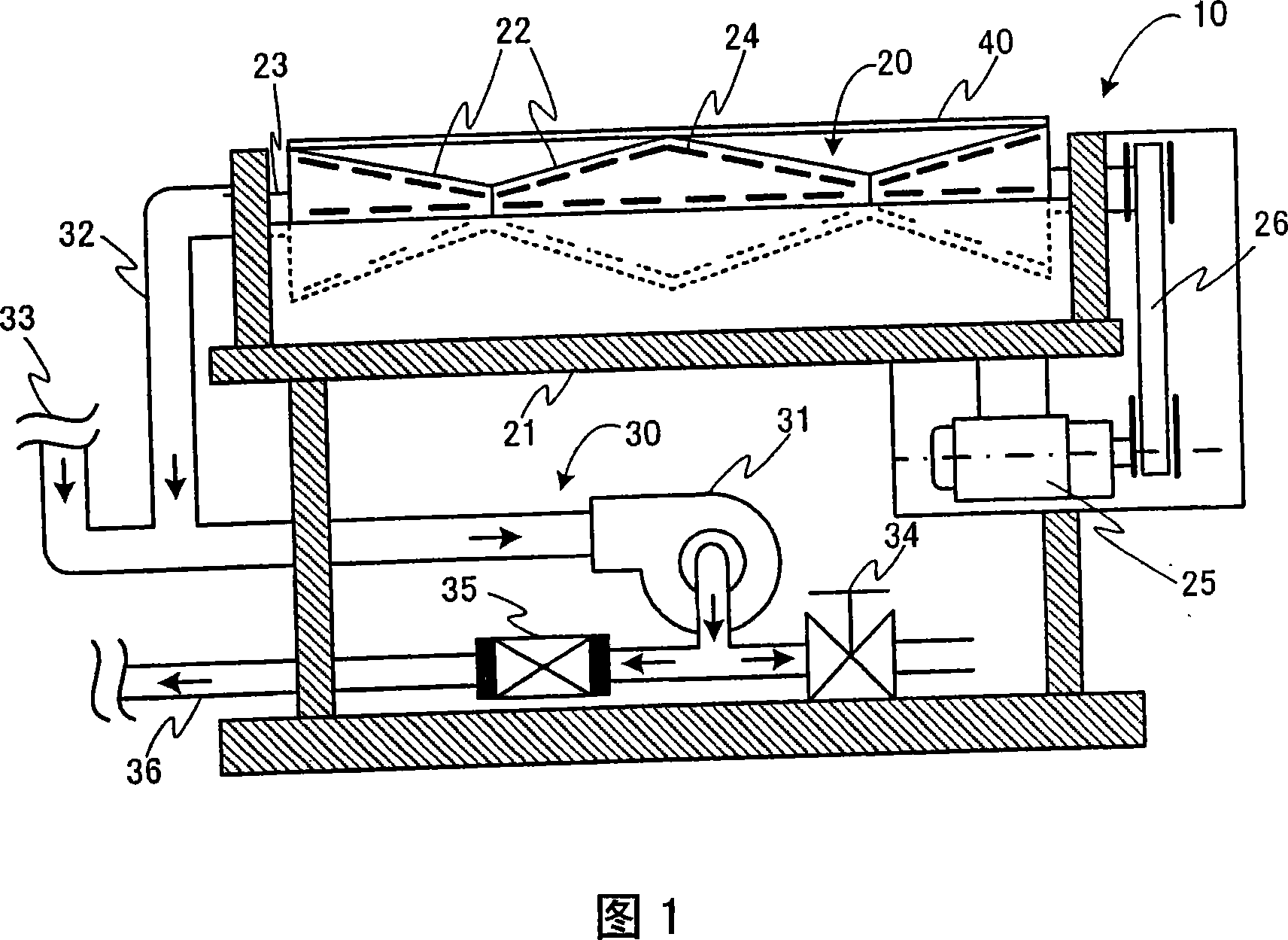

[0025] First, referring to FIG. 1, FIG. 1 illustrates a partial cutaway side view of a preferred embodiment of a substrate transfer device according to the present invention. The substrate transfer device 10 mainly includes a substrate transfer unit 20 and an air blowing / suction unit (hereinafter referred to as an air blowing / suction unit) 30 . As will be described in detail below, the substrate 40 , that is, a thin plate such as a glass substrate is conveyed in a direction perpendicular to the paper surface of FIG. 1 .

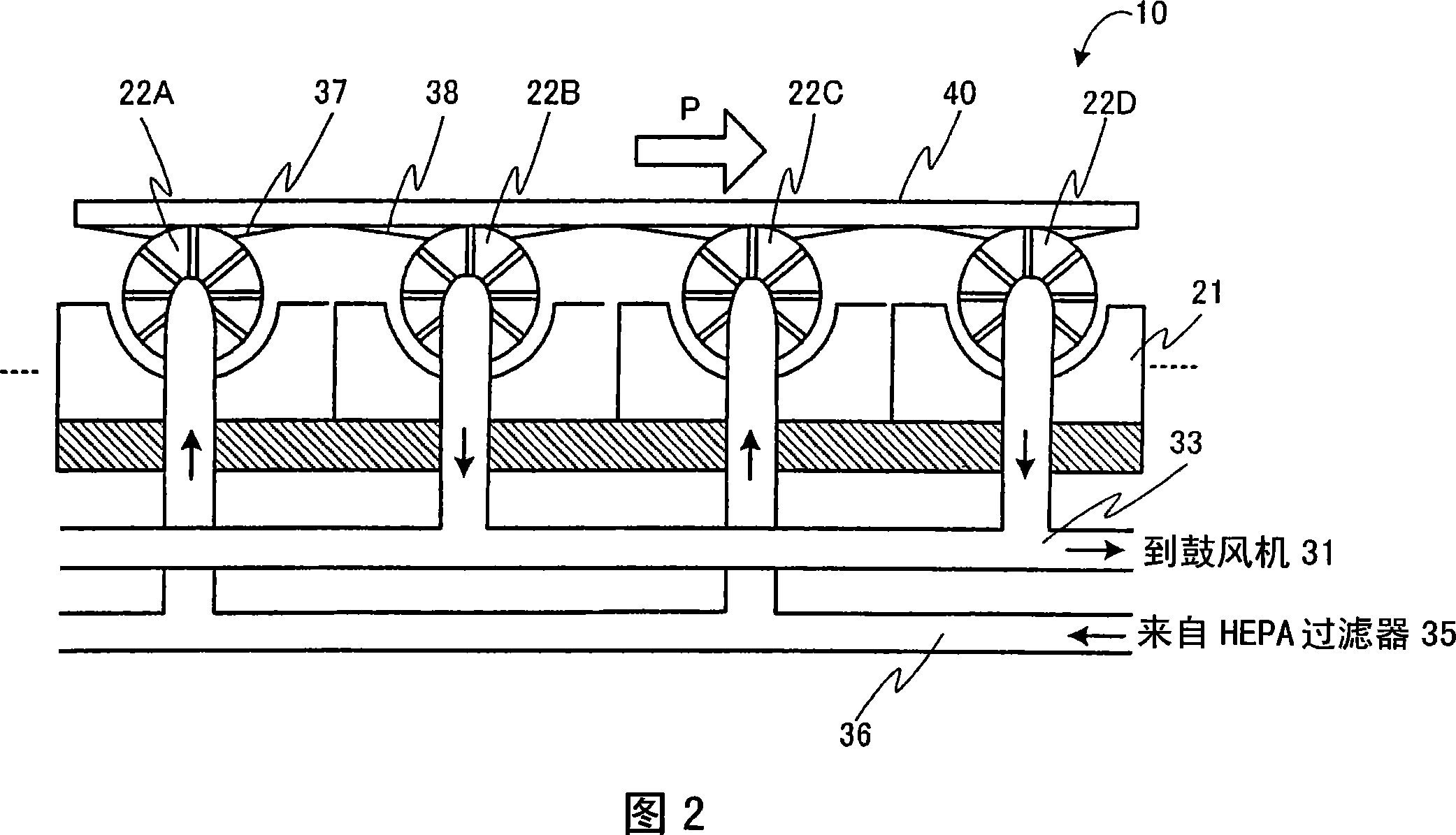

[0026] The substrate conveying section 20 includes a plurality of conveying rollers 22 through which respective rotating shafts 23 extend. Each rotating shaft 23 extends through both side walls of a frame (or block) 21 that covers the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com