Separation and purification method of valine

A purification method and valine technology, which are applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficult separation, unsatisfactory separation effect and valine yield, etc., so as to reduce sewage , Obvious effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for separating and purifying valine, comprising the steps of:

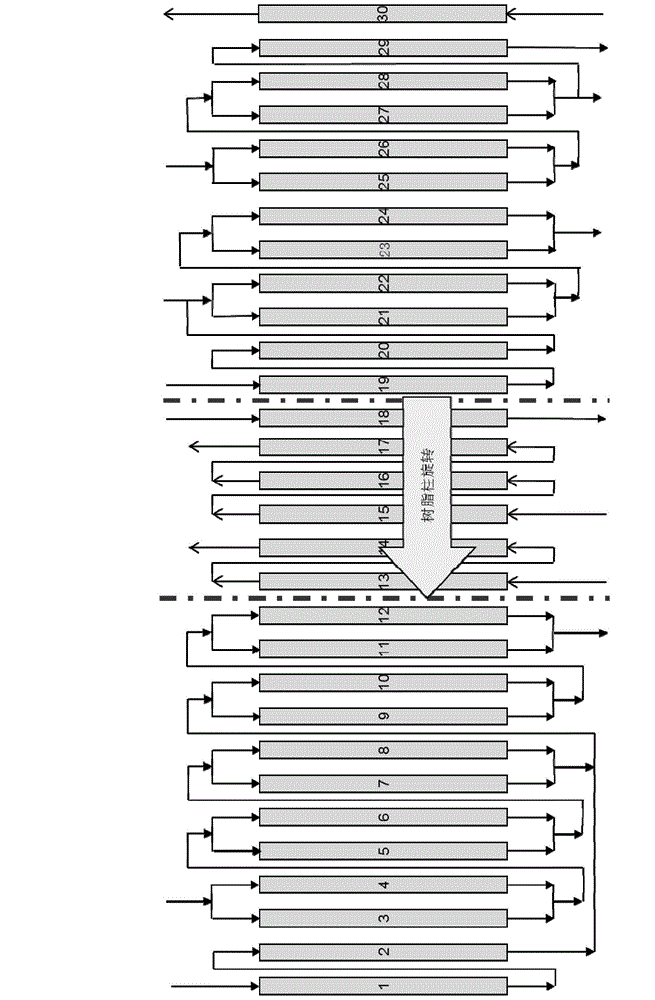

[0032] (1) After the valine fermentation broth is filtered through a plate frame, the filtrate is obtained, the pH of the filtrate is 2.0-2.5, the valine content is 2-3%, and the leucine content is 0.5-1.5%. , send the filtrate to such as figure 1 In the feed zone of the continuous moving bed of the cation exchange resin column rotating from right to left shown, the rotation period is 32h;

[0033] (2) if figure 1 As shown, the cation exchange resin column of the continuous moving bed is divided into feed area, water washing area, backwash area, product top water area, first analysis area, second analysis area, analysis liquid recovery area, The acid regeneration area and the washing acid area collect the analysis solution of the first analysis area and the second analysis area, which are used to produce pharmaceutical grade valine products and food grade valine products respectively;

[0034] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com