Preparation method of oxidized graphene polypropylene functional fiber

A functional fiber and acrylic fiber technology, applied in the field of fiber materials, can solve the problems of limited dispersion, large influence of graphene oxide dispersion, accelerated graphene oxide stacking, etc., achieve sufficient modification effect, low preparation cost, and close The effect of fast branch rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

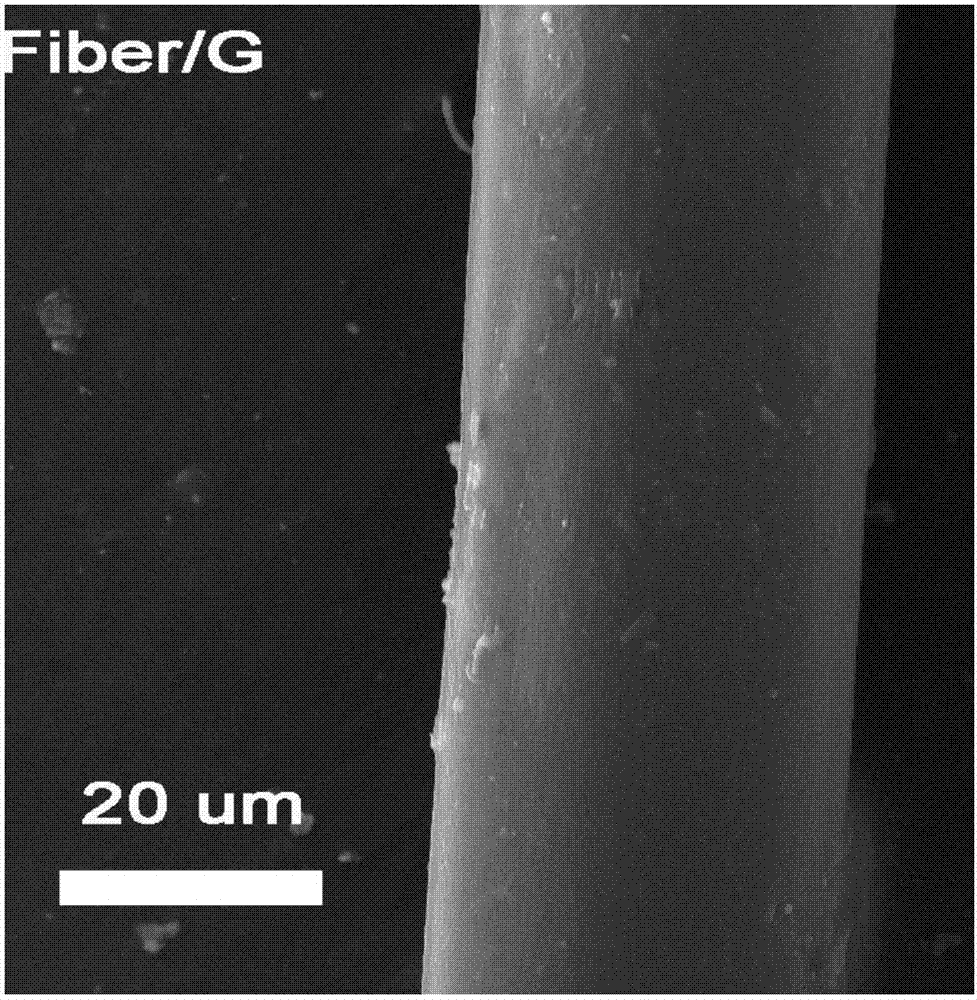

[0033] This embodiment relates to a preparation method of graphene oxide polypropylene functional fiber; the specific implementation steps are as follows:

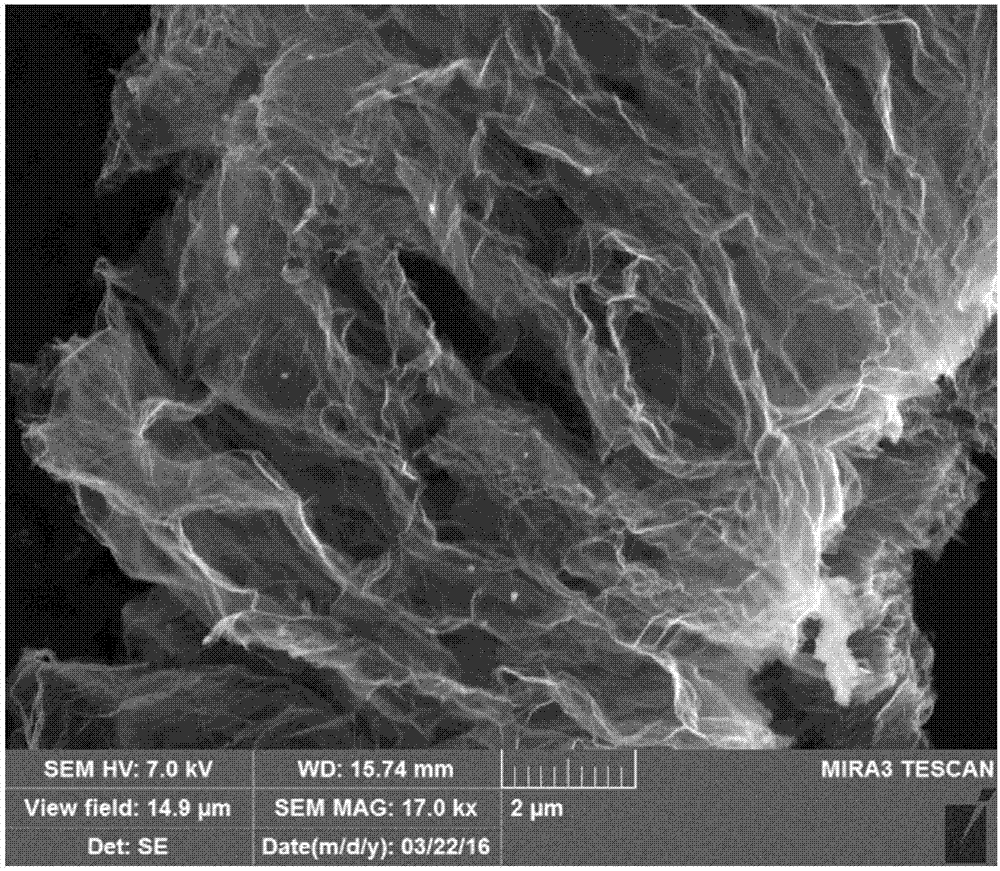

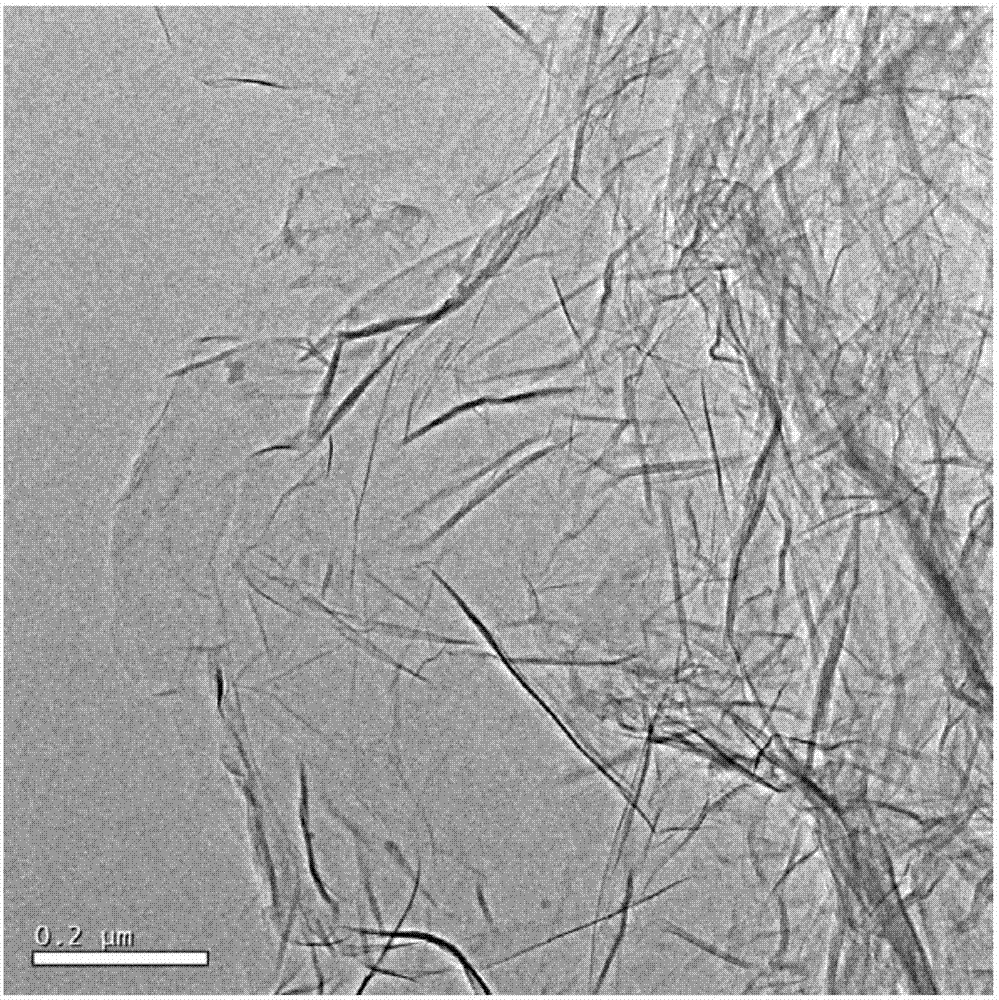

[0034]1) Surface modification modification and functionalized graphene oxide with high degree of sufficient pre-exfoliation (surface alkylation modification and modified graphene oxide) are obtained by combining graphene oxide with a modifier (octadecyl dihydroxyethyl amine oxide) through weak interactions such as hydrogen bonds and van der Waals forces and chemical bonds; the specific modification steps are: add deionized water to the graphene oxide dispersion after multiple washings and dilute it to a concentration of 1-10mg / ml, After ultrasonic treatment for 20-50 minutes, add a modifier (the mass ratio of modifier to graphene oxide is 1), control the system temperature at 10-60 degrees, stir mechanically, and wait for the graphene oxide to be completely separated from the water phase and precipitated. , suction filtrat...

Embodiment 2~4

[0039] The present embodiment 2~4 relates to a kind of preparation method of graphene oxide polypropylene fiber functional fiber; Its preparation method is the same as embodiment 1, the difference is: the dosage ratio of dry functionalized graphene oxide and polypropylene chip is respectively 0.5%wt, 1%wt, 3%wt.

Embodiment 5

[0041] This embodiment relates to a preparation method of graphene oxide polypropylene fiber functional fiber; its preparation method is the same as that of Example 1, except that:

[0042] The modifier is cetyl dimethyl amine oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com