Technical method of pigment wash, dye, and general finish for ready-made clothes in pure cotton

A process method, the technology of blue-grain washing, which is applied in dyeing, liquid/gas/steam finished product treatment, textiles and papermaking, etc., can solve the problems of poor air permeability, complexity, and low utilization rate of dyes, etc., and achieve long-lasting hand feeling Suppleness, energy consumption reduction effect, and drapability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

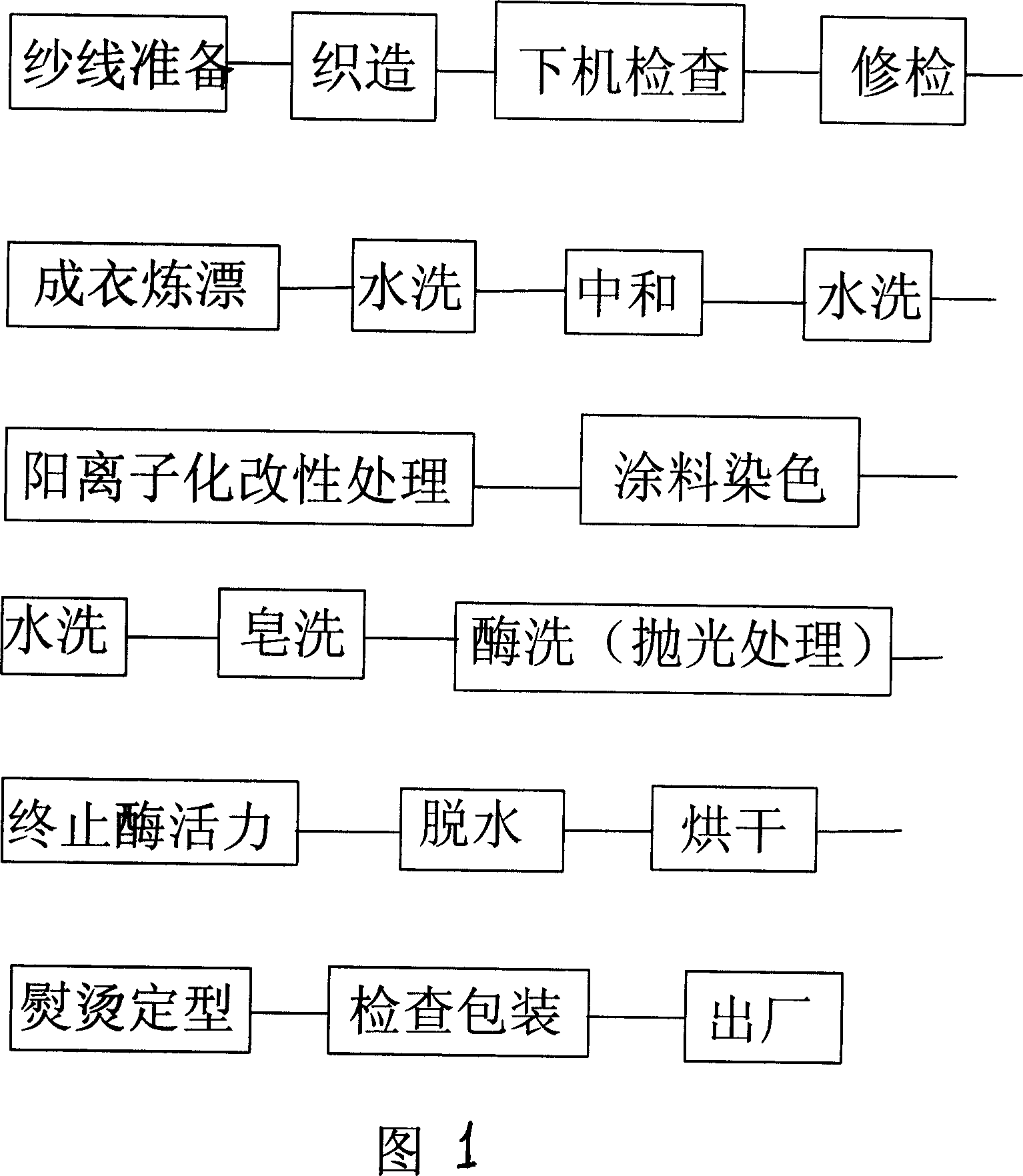

Method used

Image

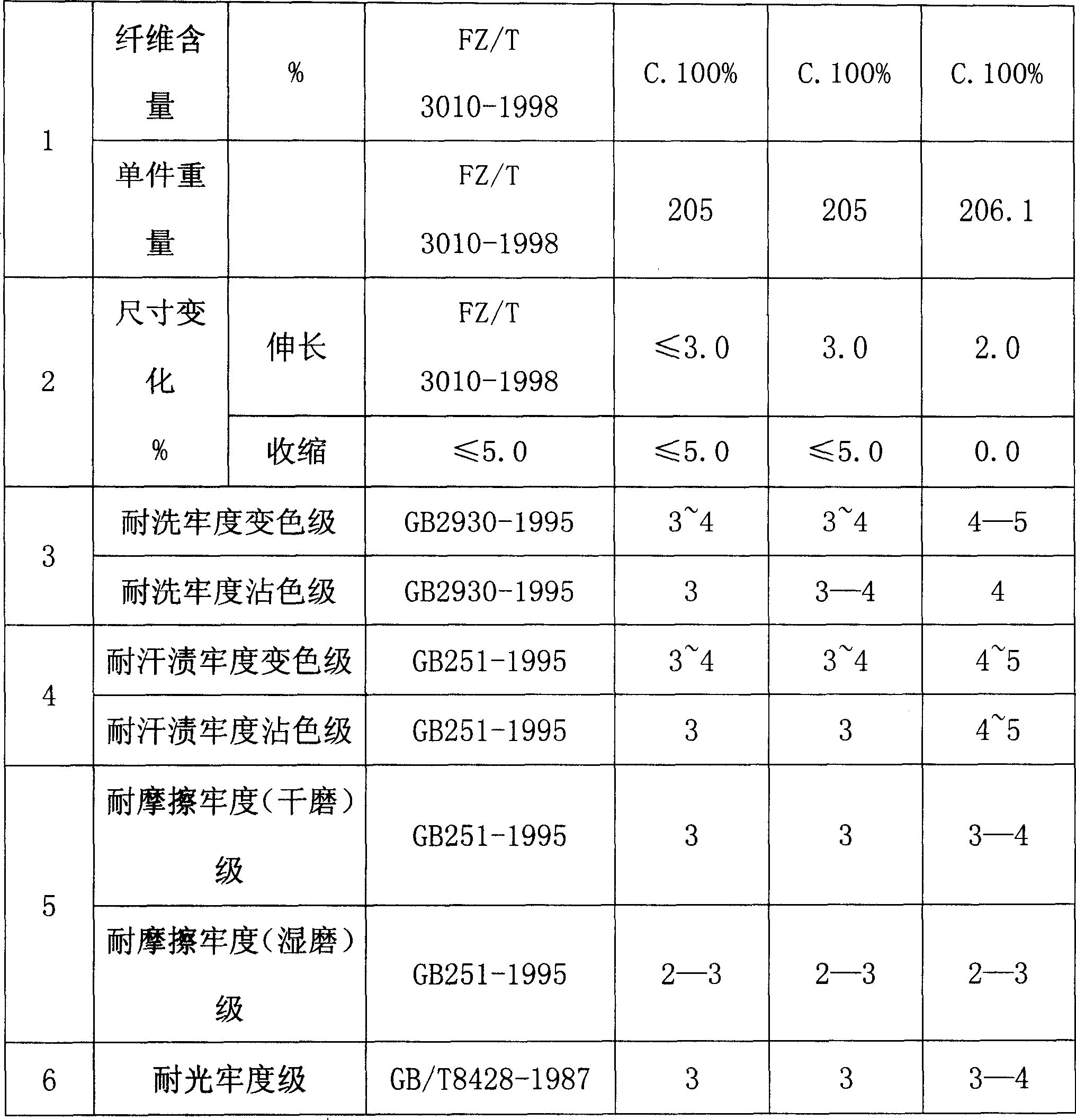

Examples

Embodiment 1

[0026] 32 counts / 2 strands of pure cotton are weaved and put into the P400 garment dyeing machine for garment refining and bleaching. The refining and bleaching solution is formulated with 1ml of penetrant red oil, 2ml of stabilizer, 9ml of hydrogen peroxide, 2g of sodium carbonate, and 1L of water. Refining and bleaching for 30 minutes at a bath ratio of 1:10-15, 95°C, and PH10.5-11. After passing the inspection, wash with water, and use 0.6% by weight of 96% acetic acid at room temperature with a bath ratio of 1:15. Under the condition of neutralization pH5.5-6.0, 30 minutes, wash with water; use cationic modifier Biwengu 1-2% by weight, at 40 ℃, bath ratio 1:10-15, PH10 for 30 minutes , and the cationic blue 54# dye M-RL and the cationic dye 29# dye X-GL are respectively made into a 0.05% dye solution, and the color is uniform and uniform on the treated fiber before proceeding to the next process; Exhaust dyeing, to be dyed pink, take 1% of the K BL type of paint purple red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com