Plastic packaging bag cutting equipment

A cutting device and packaging bag technology, applied in packaging and other directions, can solve the problem of not having a mechanism that can automatically change sides, and achieve the effect of reducing settings and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

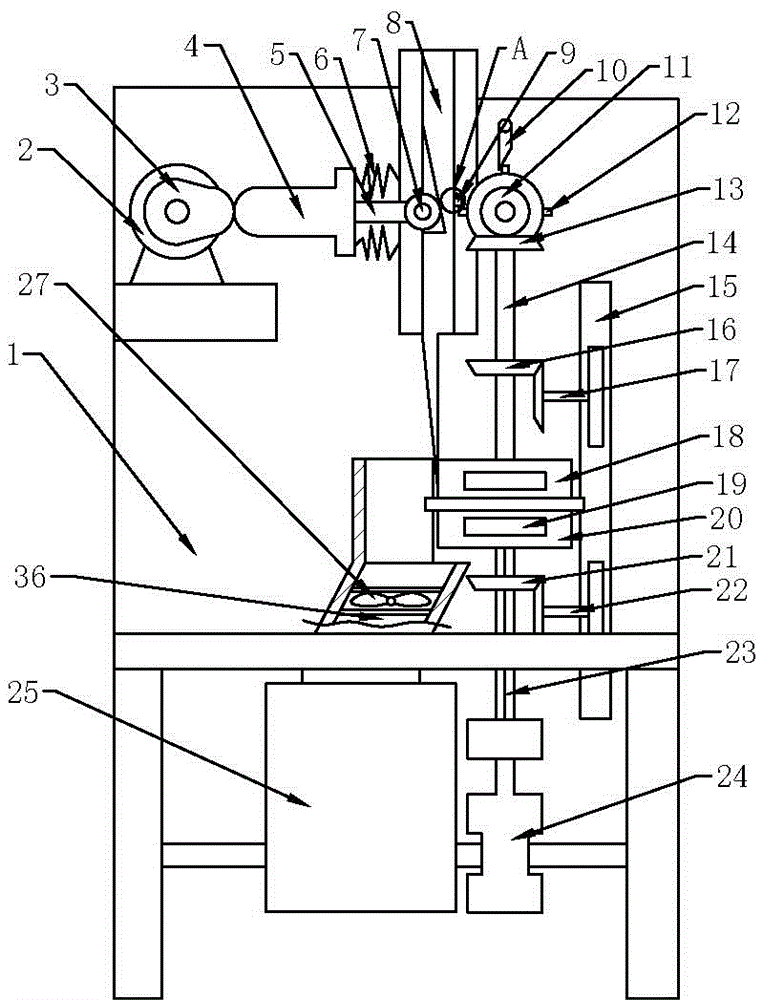

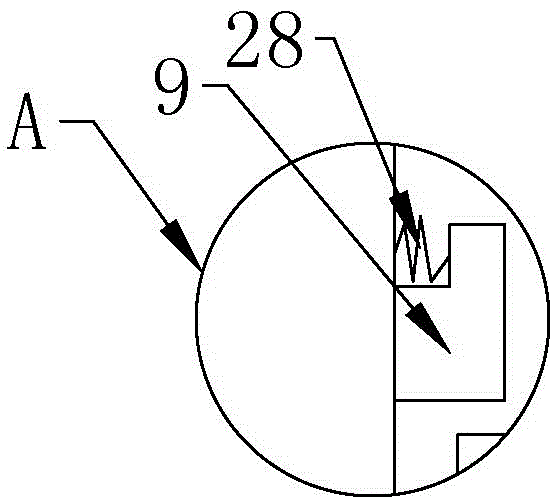

[0019] The reference signs in the drawings of the description include: frame 1, second motor 2, cam 3, ejector rod 4, output rod 5, second spring 6, roller 7, cutting knife 8, telescopic pressing block 9, stop rod 10 , second bevel gear 11, angle rod 12, first bevel gear 13, first rotating shaft 14, rack 15, third bevel gear 16, first duplex gear 17, upper platen 18, cooler 19, lower platen 20 , the fourth bevel gear 21, the second duplex gear 22, the second rotating shaft 23, the cylinder 24, the cloth bag 25, the collection pipeline 26, the negative pressure blade 27, the first spring 28.

[0020] Example figure 1 and figure 2 As shown, the plastic packaging bag cutting device includes a frame 1, a cutting knife 8 is slidingly connected to the frame 1, a telescopic pressing block 9 is slidingly connected in the cutting knife 8, and a second telescopic pressing block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com