Preparation method of high-attenuation backing material

A high-attenuation, backing technology, applied in the field of preparation of high-attenuation backing materials, can solve the problems of tungsten powder volume ratio limitation, high-attenuation metal backing cutting, difficult bonding, and sound attenuation coefficient cannot be achieved, etc. Effect of Sound Attenuation Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

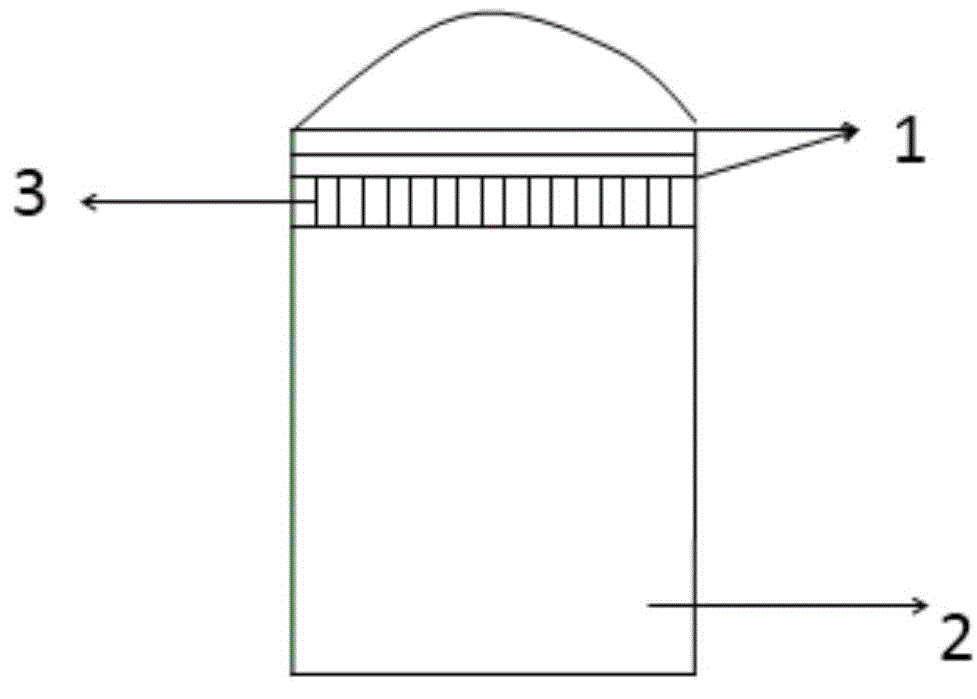

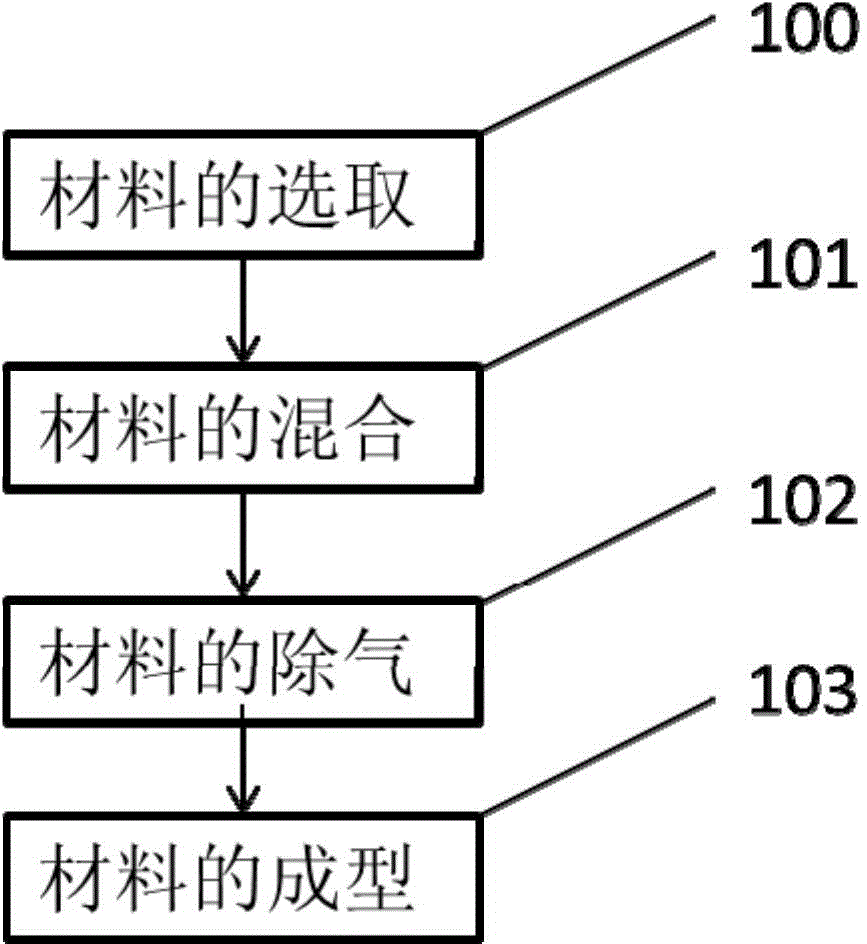

[0041] A high attenuation backing preparation method, comprising the following steps, please refer to figure 2 -4 shows:

[0042] 100. Material selection: select micron-scale tungsten powder that accounts for 10% to 60% of the total volume of the backing and polyester powder that accounts for 40% to 90% of the total volume of the backing; the micron-scale refers to 2 microns to 7 microns . The polyester is preferably one of polyurethane powder, soft polyvinyl chloride and polyamide or a mixture thereof in any proportion. The glass transition temperature of the polyester material is greater than 65°C, preferably 70-150°C.

[0043] 101. Mixing of materials: put the powder selected above into the mixing machine and mix it evenly;

[0044] In addition, in order to avoid that the particle size of the formed granule polymer is too large to meet the requirements of preparation due to the cohesion between the powder particles, the materials can also be screened after mixing. Mixe...

Embodiment 1

[0052] Embodiment 1 A high attenuation backing preparation method, comprising the following steps, please refer to figure 2 -4 shows:

[0053] 100. Material selection: choose 20% tungsten powder in the total volume of the micron-level backing and 80% polyester powder in the total volume of the backing;

[0054] 101. Mixing of materials: put the powder selected above into the mixing machine and mix it evenly;

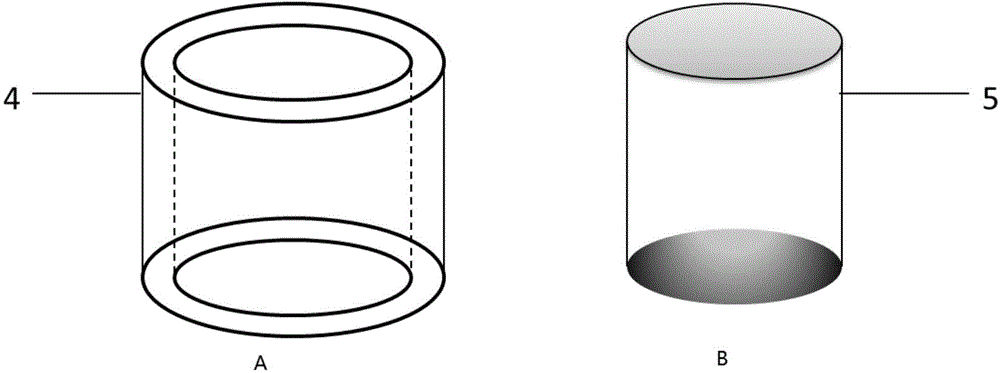

[0055] 102. Degassing of materials: place the uniformly mixed powder in the container (4), and use a vacuuming instrument to extract the air to remove the air in it;

[0056] 103. Hot pressing of materials: the hot pressing part (5) is connected to the container (4), the hot pressing part (5) is matched with the shape of the inner wall of the container (4), and the mixed powder that has been sieved and screened is uniformly put into the container (4), the hot-pressed part (5) is heated to 70°C, the interior of the container (4) is pressurized to 5MPa, and the hot-pres...

Embodiment 2

[0058] Embodiment 2 A high attenuation backing preparation method, comprising the following steps, please refer to figure 2 -4 shows:

[0059] 100. Material selection: choose 30% tungsten powder in the total volume of the micron-level backing and 70% polyester powder in the total volume of the backing;

[0060] 101. Mixing of materials: put the powder selected above into the mixing machine and mix it evenly;

[0061] 102. Degassing of materials: place the uniformly mixed powder in the container (4), and use a vacuuming instrument to extract the air to remove the air in it;

[0062] 103. Hot pressing of materials: the hot pressing part (5) is connected to the container (4), the hot pressing part (5) is matched with the shape of the inner wall of the container (4), and the mixed powder that has been sieved and screened is uniformly put into the container (4), the hot pressing part (5) is heated to 150°C, the interior of the container (4) is pressurized to 15MPa, and the hot p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com