Improved simulated moving bed separation method

A technology for simulating moving bed and separation methods, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve problems such as increasing system operating pressure and solvent consumption, and achieve the goal of reducing consumption and system operating pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

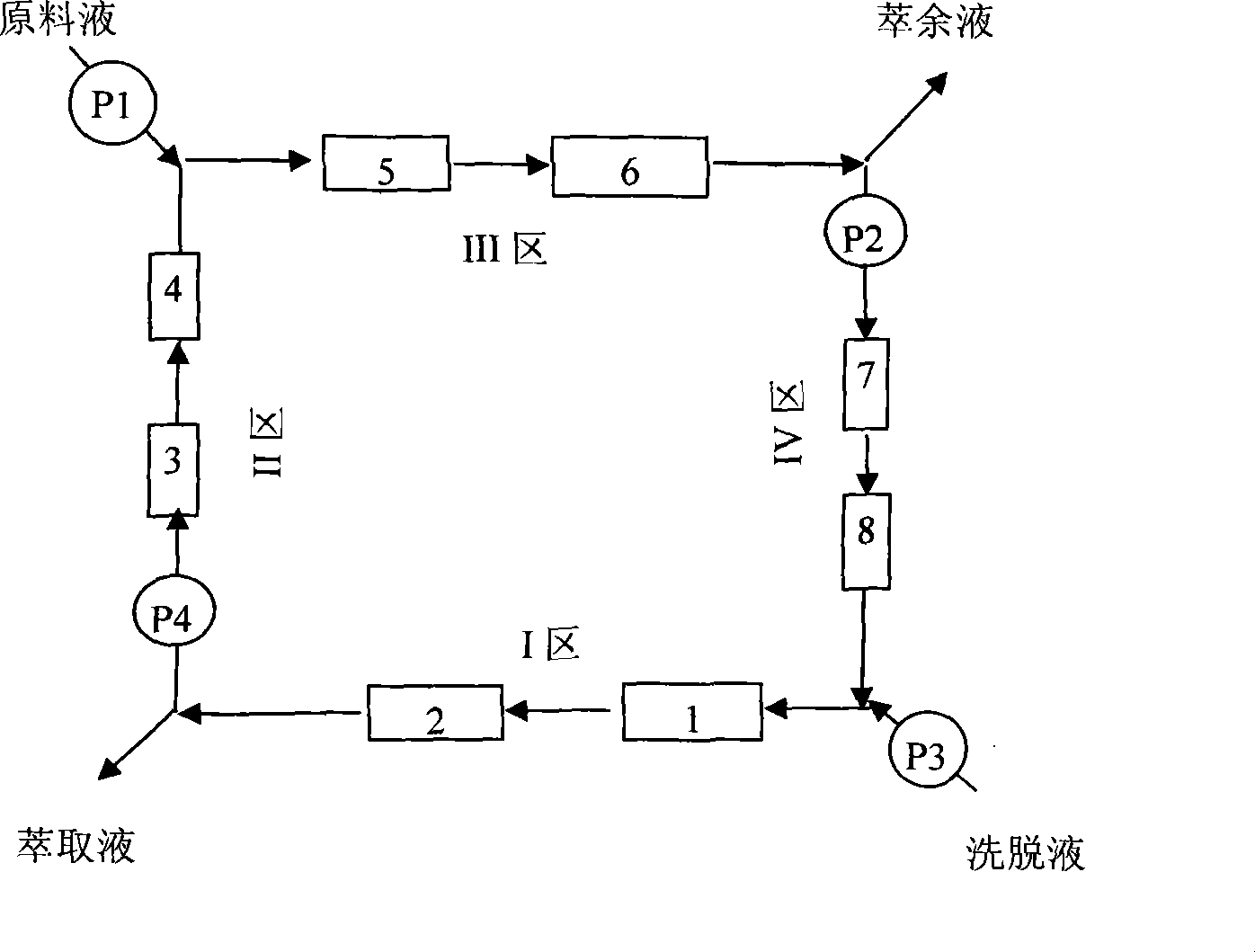

[0041] Improved Simulated Moving Bed Separation Method A

[0042] use as figure 2 In the separation system shown, prepare a saturated racemic omeprazole raw material solution with a concentration of 2 mg / mL with n-hexane / absolute ethanol (volume ratio 80 / 20), and inject it at a flow rate of 17.5 mL / min. The pump P1 is directly pumped into the III area formed by the chromatographic column 5 and the chromatographic column 6, and then flows through the IV area formed by the chromatographic column 7, 8 and the IV area circulation pump P2, and normal hexane / dehydrated alcohol (volume ratio is 80 / 20) At a flow rate of 7mL / min, pump the eluent through the eluent pump P3 from the eluent inlet between the IV zone and the I zone composed of chromatographic columns 1 and 2, and then flow through the chromatographic column 3, 4 and II zone circulation pump Zone II composed of P4. The flow rates in areas I to IV were set at 23, 14.5, 17.5, and 12 mL / min, respectively. According to the...

Embodiment 2

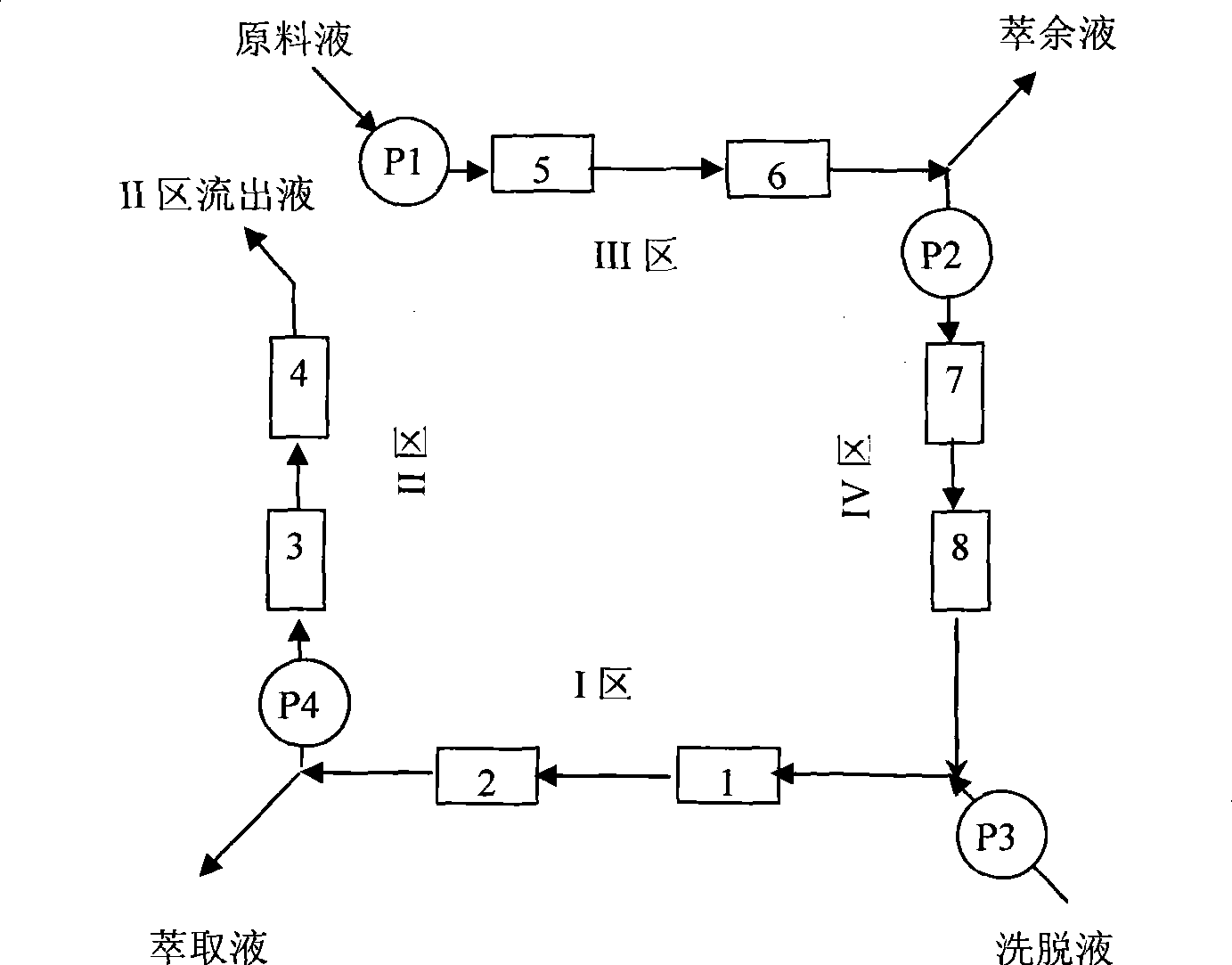

[0045] Improved Simulated Moving Bed Separation Method B

[0046] use as image 3 In the separation system shown, prepare a saturated racemic omeprazole raw material solution with a concentration of 2 mg / mL with n-hexane / absolute ethanol (volume ratio 80 / 20), and inject it at a flow rate of 17.5 mL / min. Pump P1 directly pumps into the III area composed of chromatographic column 5 and chromatographic column 6, and then flows through the IV area composed of chromatographic column 7, 8 and IV area circulation pump P2, and flows pure absolute ethanol from The eluent inlet is directly pumped into zone I composed of chromatographic column 1 and chromatographic column 2 through eluent pump P3, and then flows through zone II composed of chromatographic column 3, 4 and zone II circulation pump P4. The flow rates in areas I to IV were set at 3.1, 2.4, 17.5, and 12 mL / min, respectively. According to the material balance of the mobile phase, the flow rates of the extract and raffinate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com