Method for production of hydroxylammonium phosphate in the synthesis of caprolactam

A technology of caprolactam and oxygen, which is applied to the preparation of lactam, oxime preparation, chemical instruments and methods, etc., can solve the problems of increased production capacity, large capital investment, etc., and achieve the effect of reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

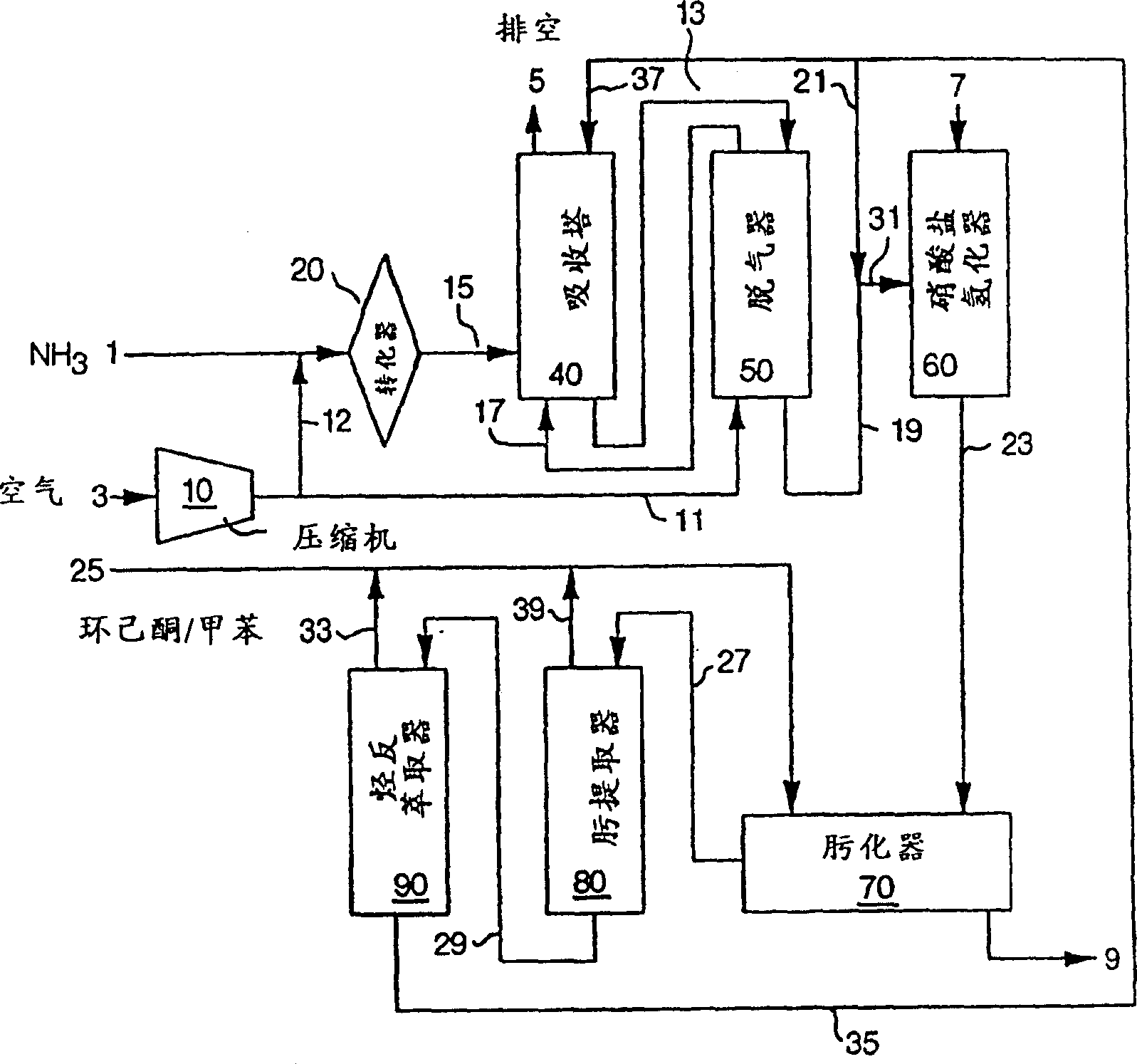

Method used

Image

Examples

Embodiment

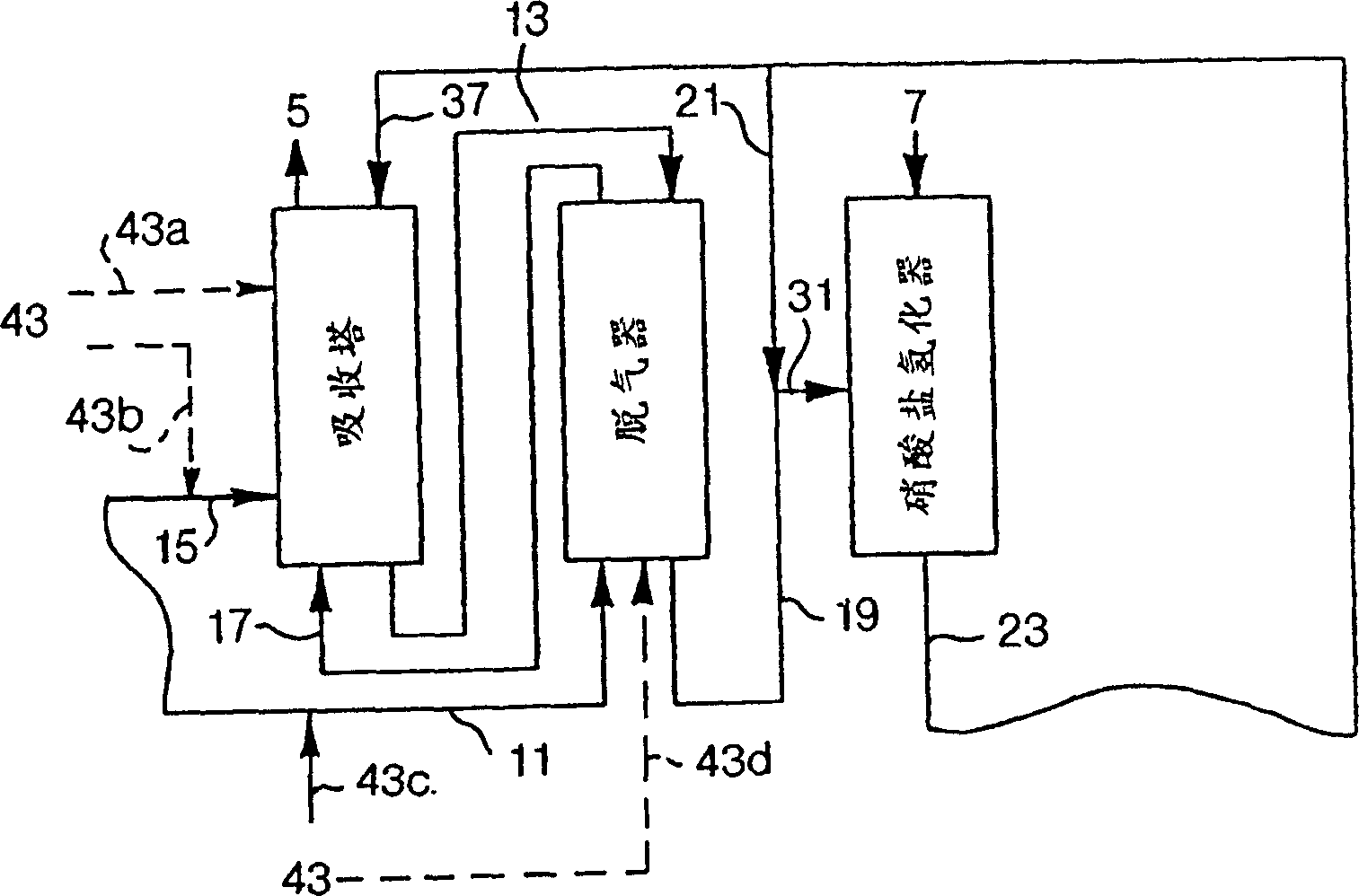

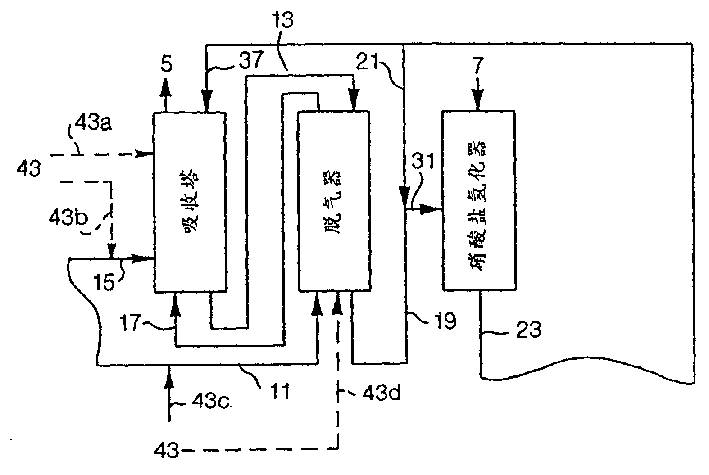

[0060] The process of the present invention is used to retrofit an existing caprolactam production plant using the DSM-HPO process, where the upper part of the absorption tower has been damaged. This in turn reduces the reoxidation of NO to NO by the absorber 2 and the ability to absorb nitrate ions. As a result, production is limited and nitrogen oxide emissions increase.

[0061] test

[0062] Therefore, in these tests, about 50-100% of the secondary air stream was diverted from the deaerator to the converter. Oxygen is added at a rate of 3.2-3.8 moles per mole of ammonia added. Oxygen addition removes dissolved NO from nitrate-rich stream 2 , thereby helping to increase NO to NO 2 oxidation and an increase in hydroxylammonium phosphate production of up to 9.8%. Furthermore, said increase in the production of hydroxylammonium phosphate is obtained without an increase in the nitrogen oxide content of the exhaust gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com