Round pipe cutting and end face grinding integrated machine

An all-in-one machine and round tube technology, applied in the direction of pipe shearing device, shearing device, other manufacturing equipment/tools, etc., can solve the problems of increasing labor cost, cutting human body, wasting time, etc., and achieving the effect of reducing manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

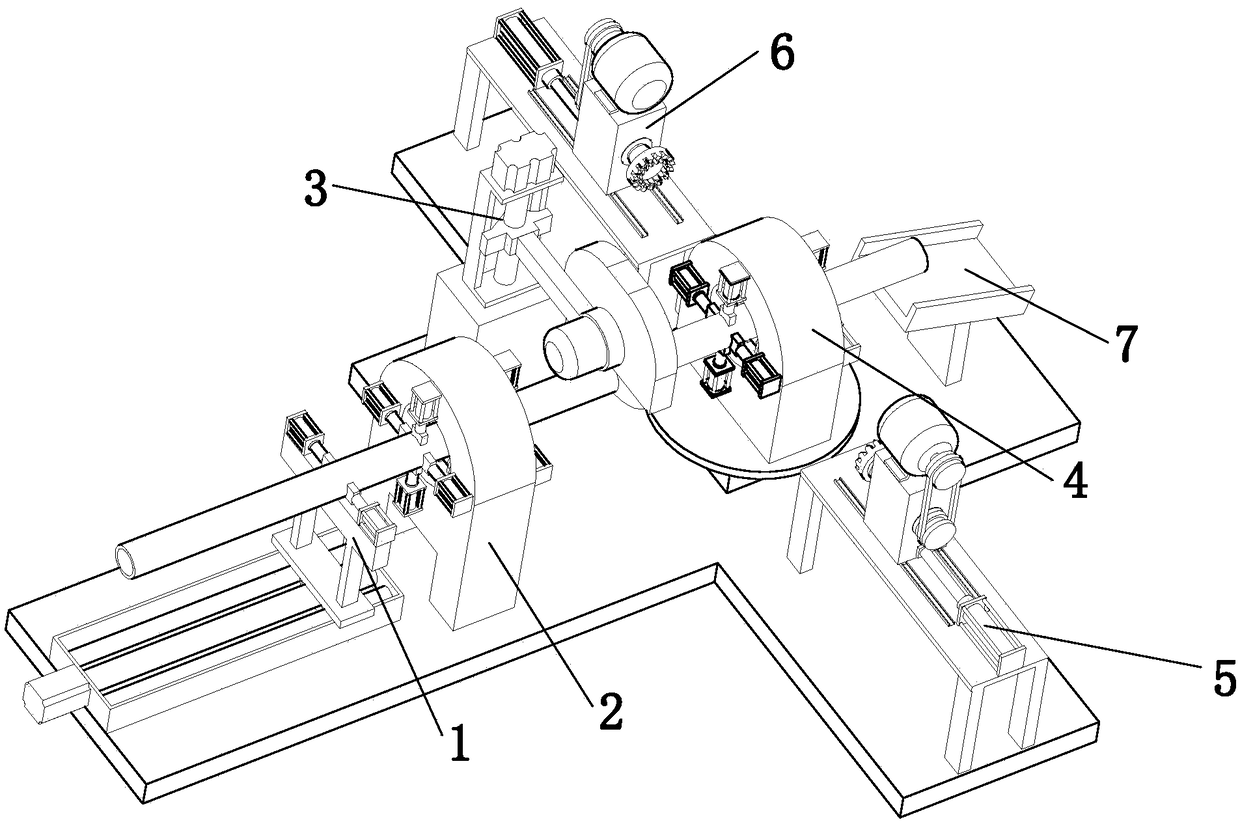

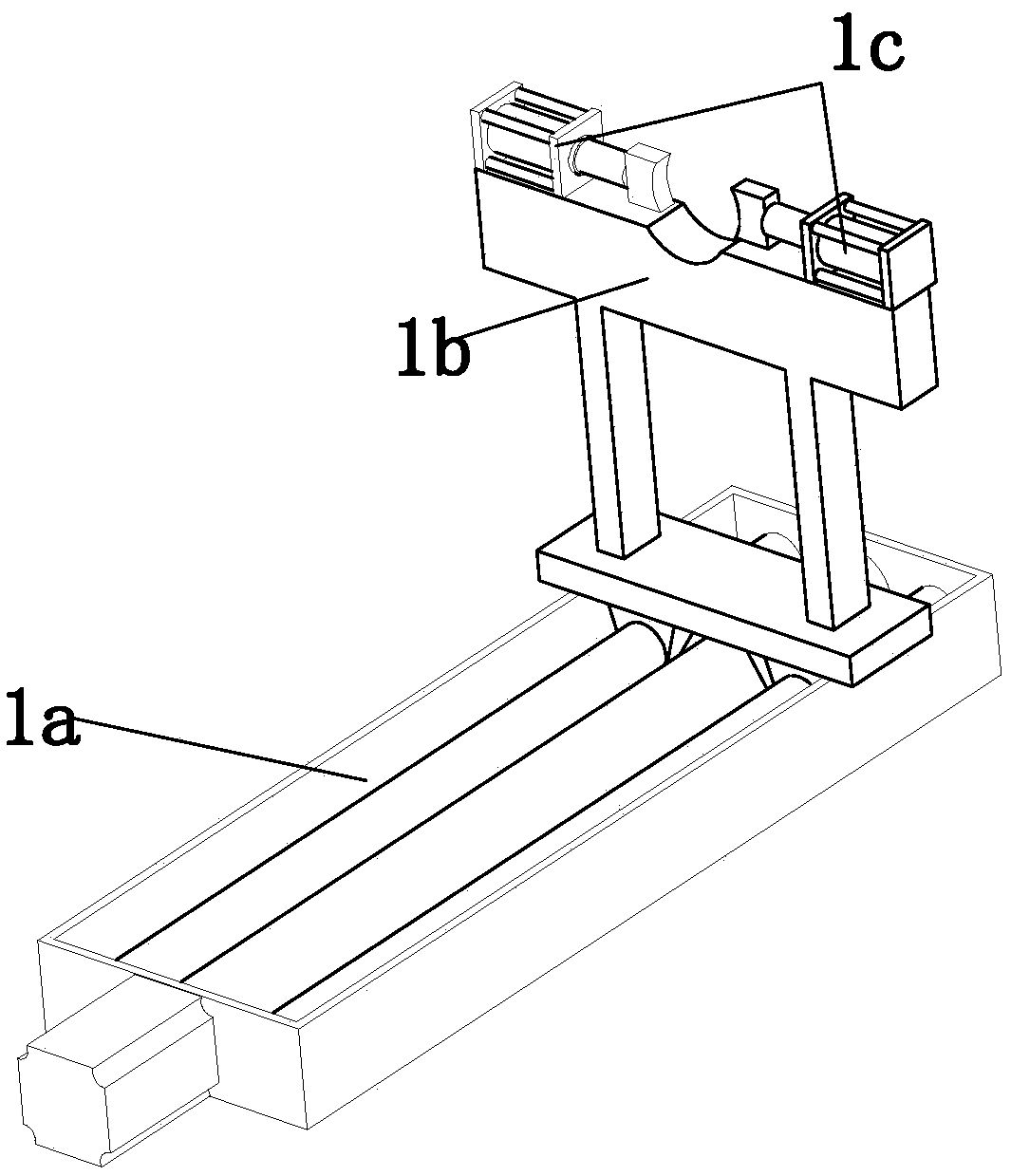

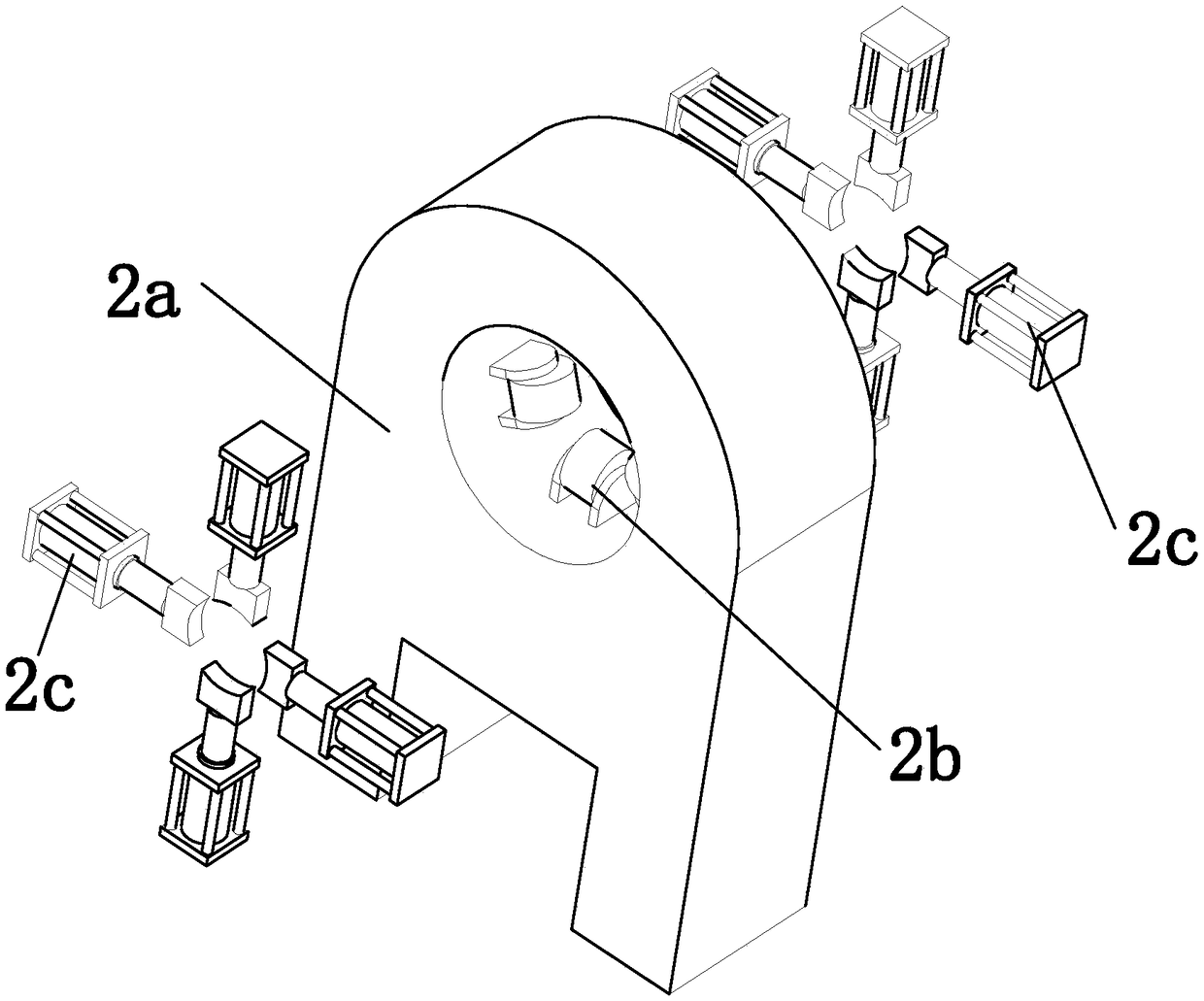

[0023] refer to Figure 1 to Figure 6 A round pipe cutting and end face grinding machine shown in the figure includes a bottom plate, and also includes a feeding assembly 1, a first clamping assembly 2, a cutting assembly 3, a second clamping assembly 4, a first grinding assembly 5 and a second grinding assembly Assembly 6, the second clamping assembly 4 includes a rotary table 4a, a second fixed seat 4b, a second pulley 4c and several second clamping cylinders 4d, the rotary table 4a includes a rotary motor, a motor mounting shell 4a2 and a turntable 4a3, The motor mounting shell 4a2 is installed on the base plate, the rotating motor is arranged inside the motor mounting shell 4a2 and the output end is set upwards, the rotating disk 4a3 is connected to the output end of the rotating motor in a horizontal state, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com