Automatic foam cutting machine and cutting method

A cutting method and cutting machine technology, applied in the direction of metal processing, etc., can solve the problems of laboriousness, difficulty, and no replacement of special equipment, etc., and achieve the effect of convenient and rapid cutting, accurate and reliable operation of equipment, and adjustable working force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

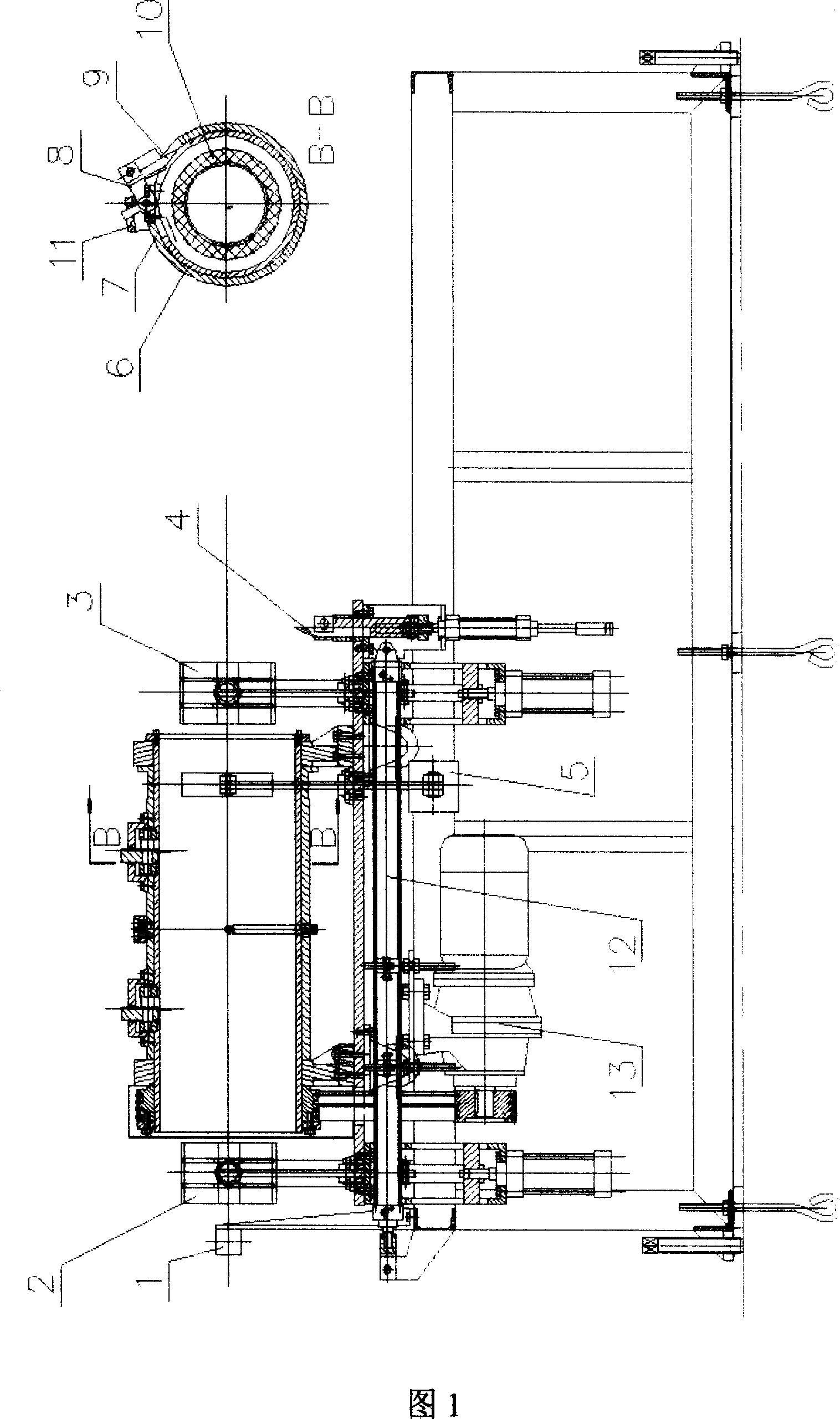

[0036] As shown in FIG. 1 , it is a structural diagram of the automatic foam jacket cutting machine according to the embodiment of the present invention. Including: steel pipe joint detector 1, clamps 2, 3, slitting knife 4, damping device 5, inner cylinder 6, outer cylinder 7, tool holder 8, ring cutter 9, online foam jacket tube 10, dead iron 11 , Cutting trolley 12 , motor 13 , connecting piece 14 , grab hook 15 , rocker arm manipulator 16 .

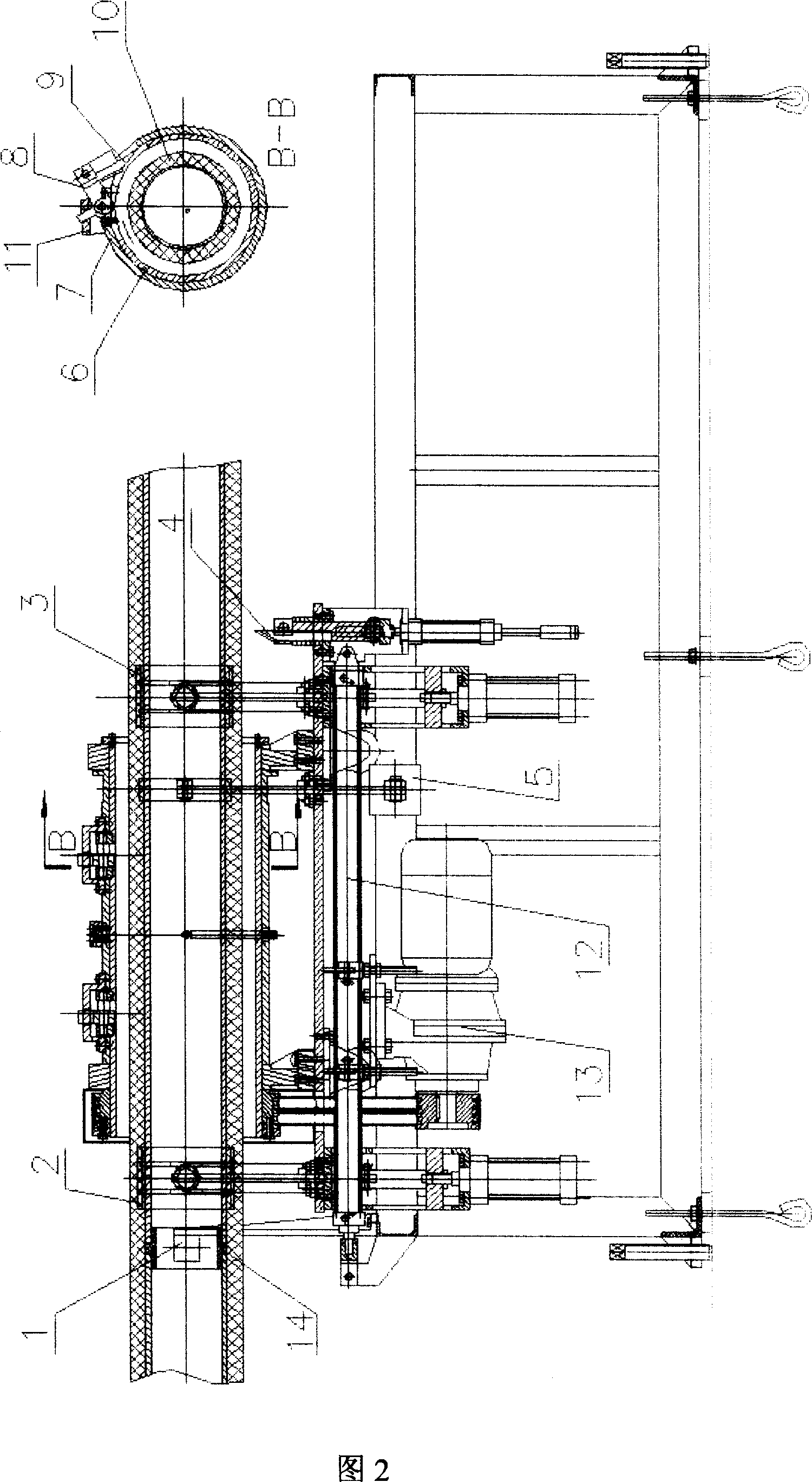

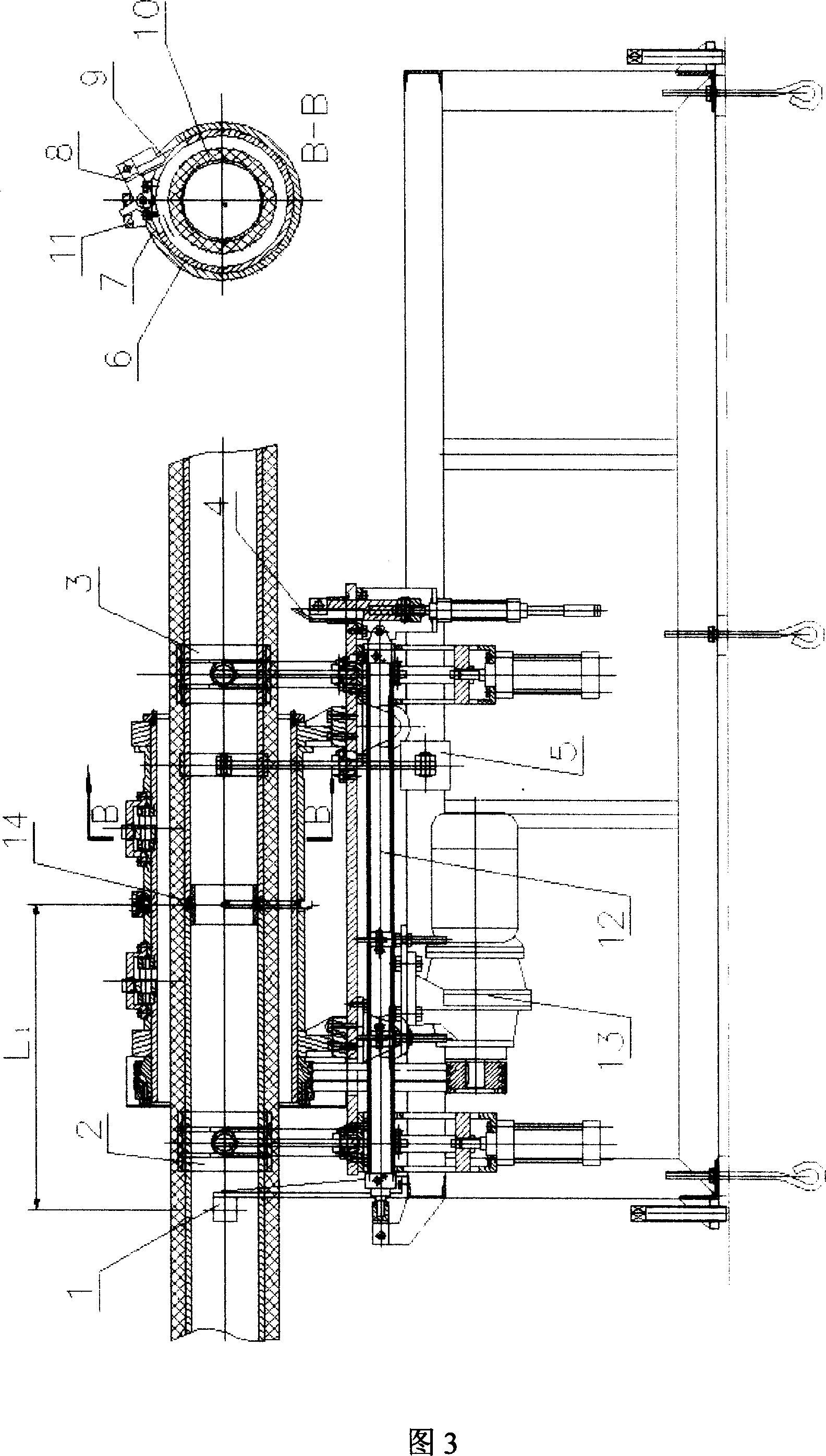

[0037] As shown in FIG. 2 to FIG. 9 , they are respectively state diagrams of the automatic foam jacket cutting machine according to the embodiment of the present invention in steps 1 to 8 of the cutting process. When the steel pipe joint covered by the foam jacket insulation layer in the previous process enters from one end of the equipment and passes through the steel pipe joint detector, a signal is sent from the detector. A series of actions are controlled by the microcomputer:

[0038] When the microcomputer detection data meet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com