Numerical-control single-plate bilateral synchronous edging machine

An edge trimming machine and bilateral technology, which is applied in the field of CNC veneer bilateral synchronous edge trimming machine, can solve the problems of large changes in metallographic structure, low efficiency, and no new process flow, etc., and achieve the effect of continuous processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

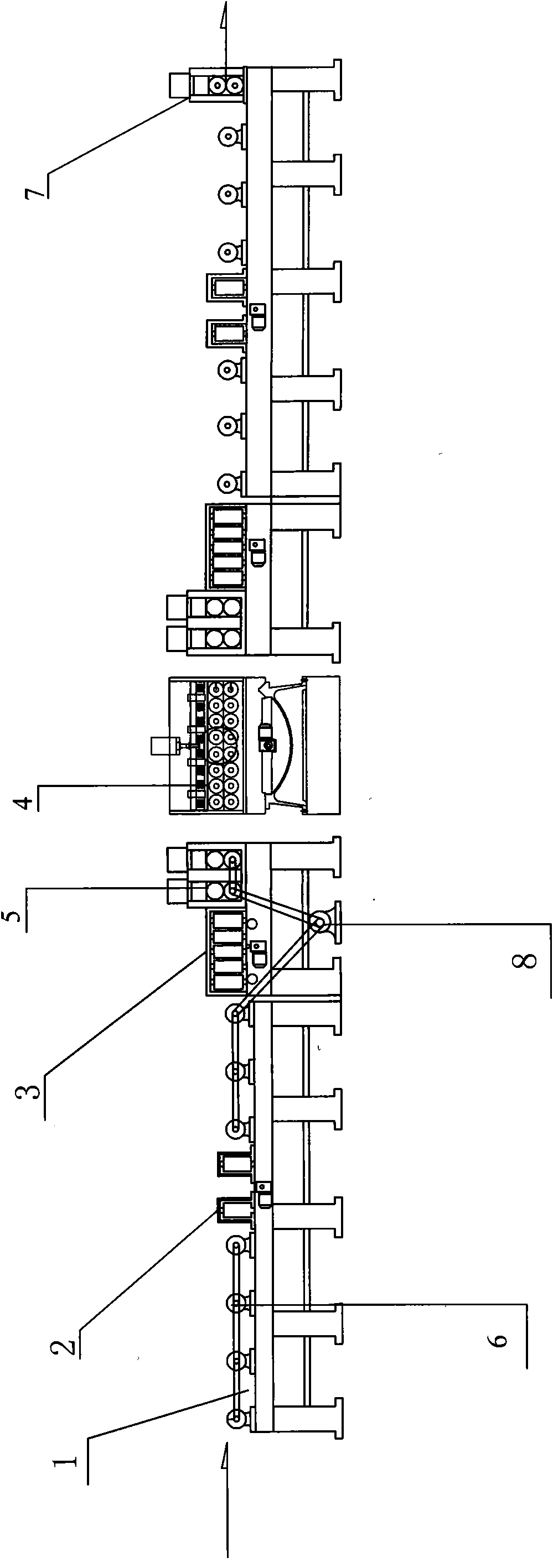

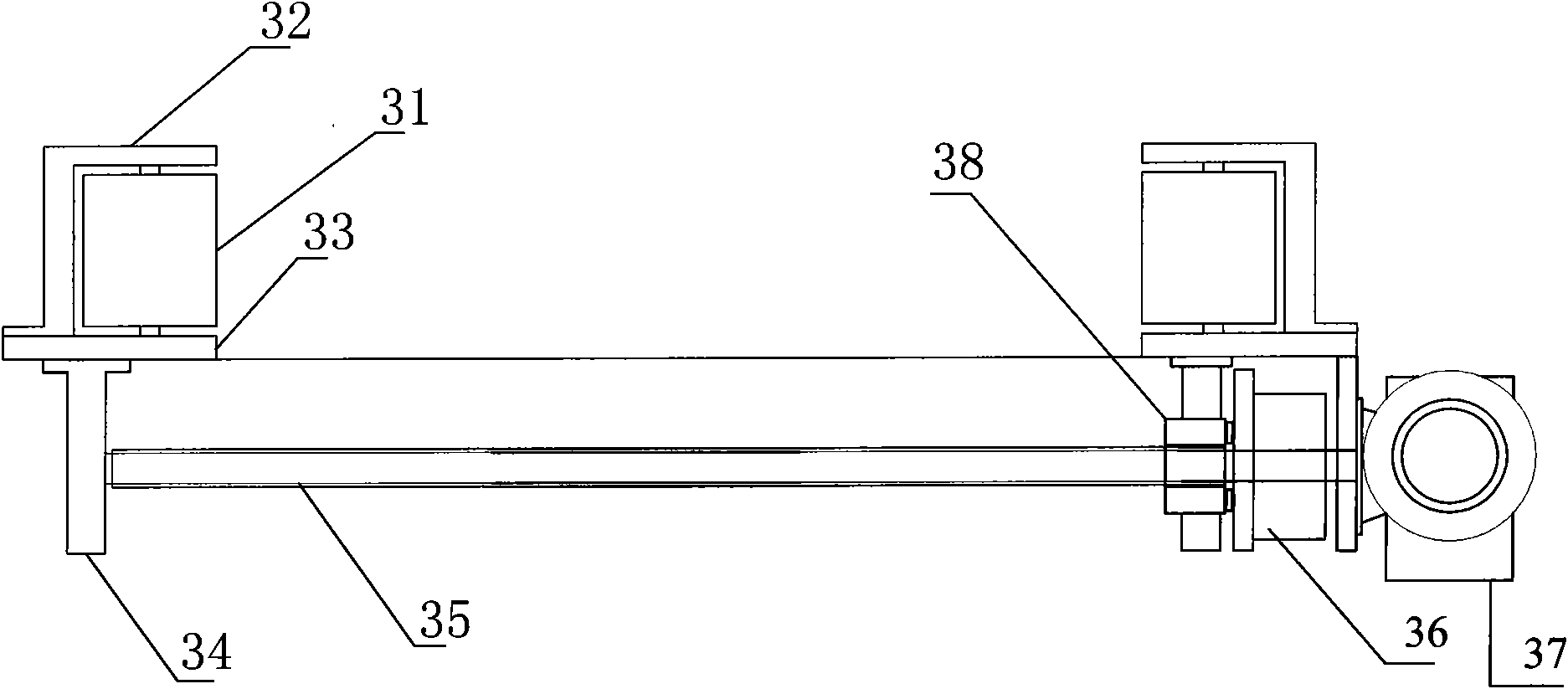

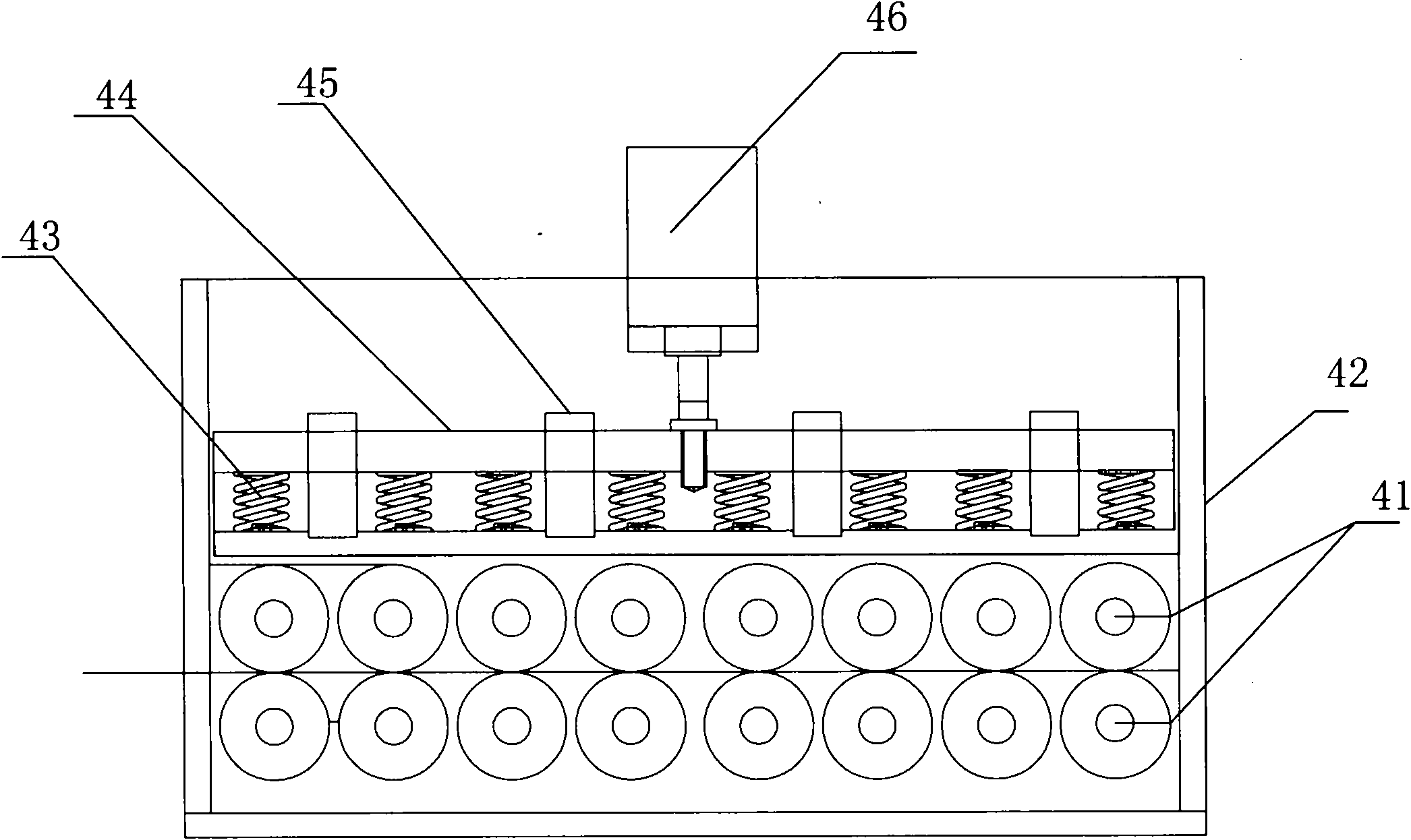

[0012] Such as figure 1 As shown, it includes various equipment set on the workbench 1 and the connected numerical control system, including the double-roller two-point correction mechanism 2, the feeding roller 6 and its transmission system 8, the pressing roller 5 and the throwing mechanism 7 Connected in sequence, between the double-roller two-point correction mechanism 2 and the feeding roller 6, a close-roller multi-point correction mechanism 3 and a flexible pressure roller device 4 are arranged, and a circle is arranged on the bottom plate of the double-roller two-point correction mechanism 2 Shaped strong sheathed wheels.

[0013] The numerical control system is a control system composed of PRC, servo system, frequency converter and touch screen. The signal acquisition of each system is completed by digital modules, which realizes the start, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com