Device for accurately cutting pre-cut seam of asphalt mixture semi-circular bending tensile test piece

A technology for asphalt mixtures and test pieces, which is applied in the direction of measuring devices, preparation of test samples, analysis of materials, etc., can solve the problems of irregular shape of test pieces, different pre-cut seams, etc., and meet cutting requirements, easy manipulation, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific working method of the present invention will be described in detail below in conjunction with the accompanying drawings.

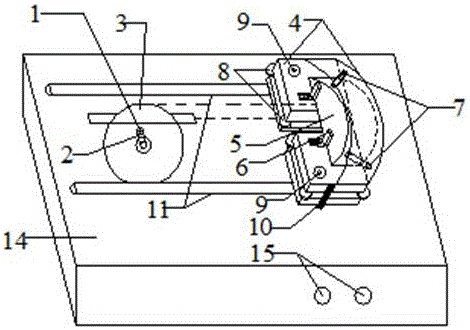

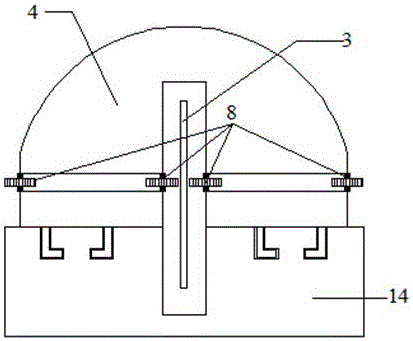

[0035] like figure 1 As shown in the figure, a device for pre-cutting semicircular curved tensile test pieces of asphalt mixture with precision, which includes a horizontal operating table 14, which is equipped with a motor 1 and a saw blade 3 inside, and the motor 1 and the saw blade 3 are connected through the connecting shaft 2 The transmission connection drives the rotation of the saw blade 3 through the motor 1, and a part of the saw blade leaks out of the horizontal operating table 14; on its upper surface is provided a fixed container 4 for an asphalt mixture semicircular curved tensile test piece and two "T"-shaped slide rails 11, The specimen holder 4 can slide in the "T" type sliding track 11.

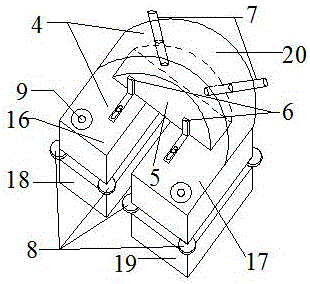

[0036] like figure 2 As shown, a special fixed container 4 for asphalt mixture semicircle bending tensile test piece, it includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com