Rapid conical head fusing machine for steel wire rope

A technology of conical head and steel wire rope, which is applied in the direction of resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unsatisfactory effect, laborious, inconvenient installation and use, and solve the problems of fixed-length head and cutting, Convenient and fast cutting to length, convenient and firm fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

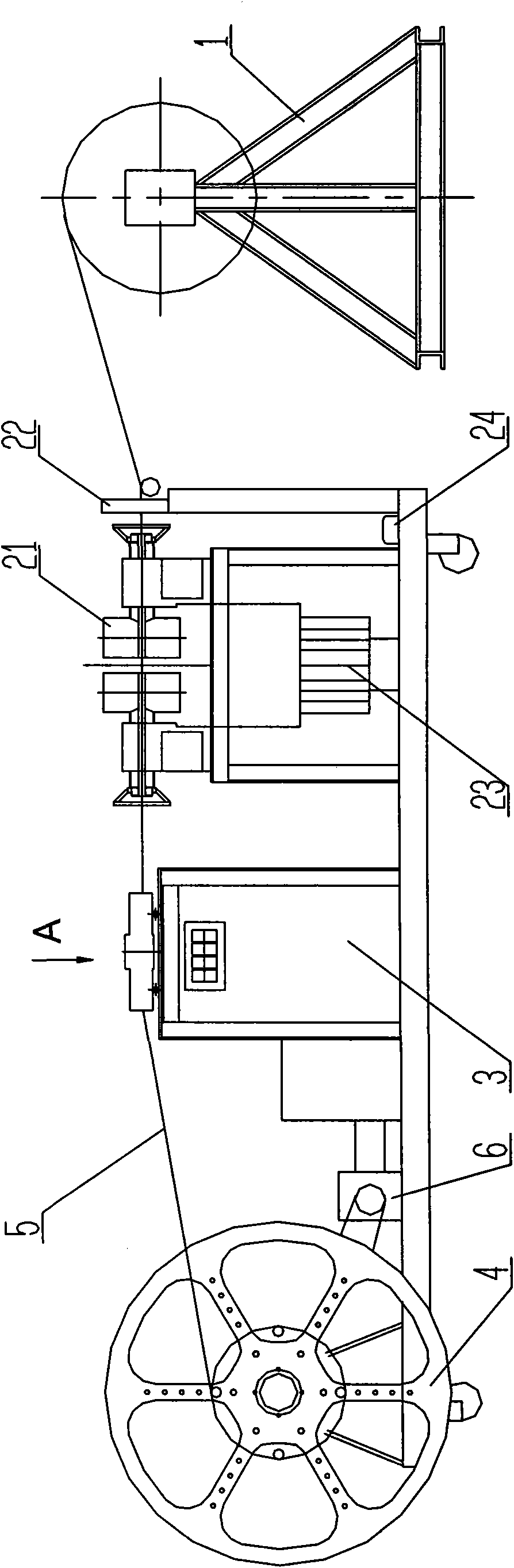

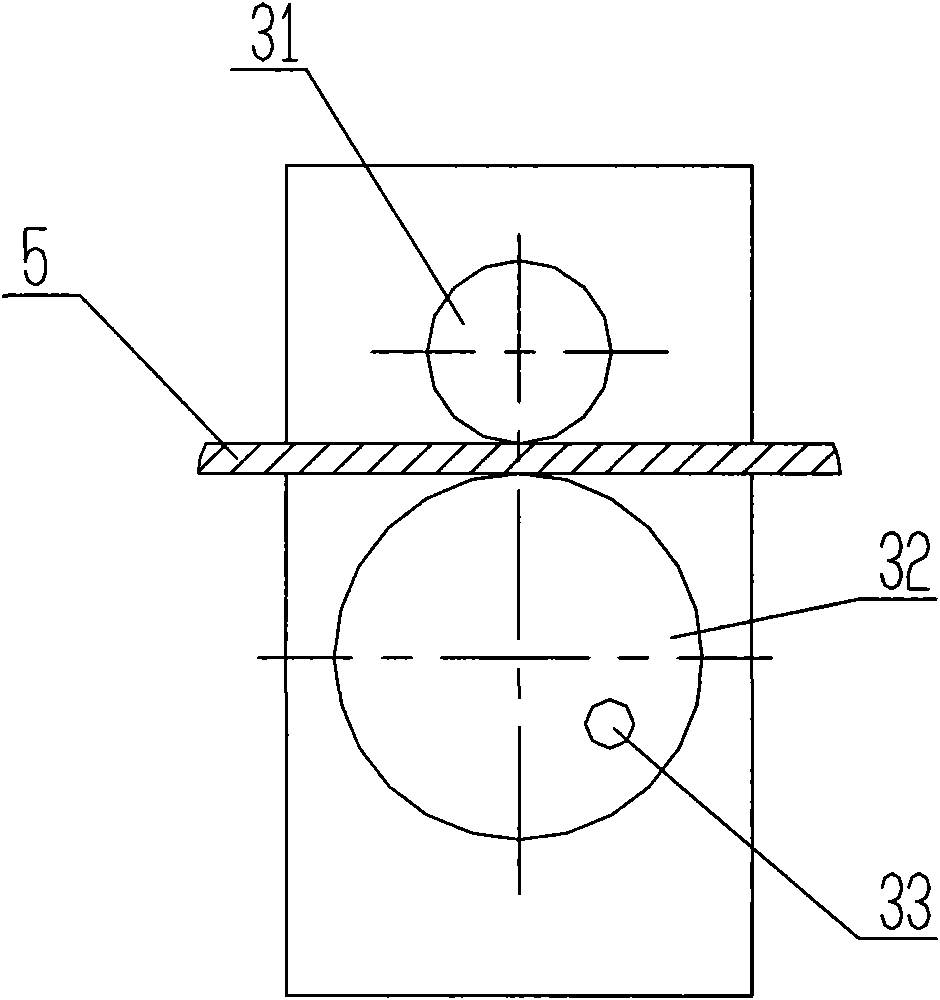

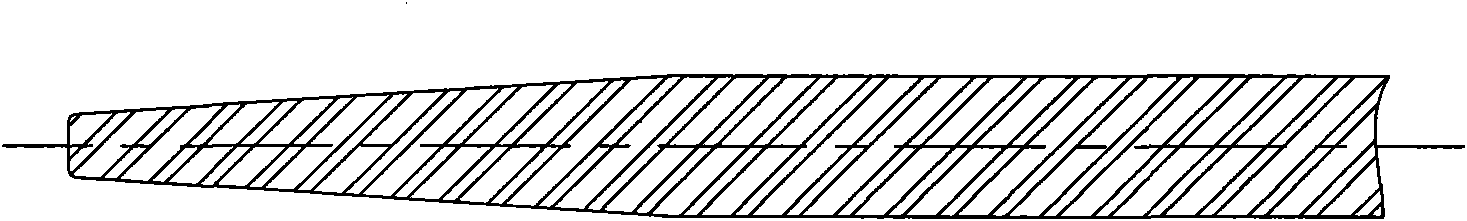

[0013] as attached figure 1 with 2 As shown, the structure schematic diagram of the rapid conical head fusing machine for steel wire rope of the present invention is given, including a pay-off frame 1, a take-up device 4, an automatic length-setting device 3 and a conical fusing device, the conical The fuse device consists of a transformer 23, a locking device 21 and a rotating handle 22, which can generate a large current to heat the wire rope 5 to a red state within the set fusing distance, and further unscrew it through the locking device 21 and the rotating handle 22. Wire rope 5 makes the rope end into a cone, and its shape is as image 3 Shown; Described automatic sizing device comprises pressure wheel 31 and the eccentric counting wheel 32 that Hall switch 33 is housed, can count the number of turns that meter counting wheel 32 rotates and be converted into the wire rope length that passes through, and the length of sizing counting device The technology adopts the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com