Rectangular section bamboo forming device and method

A rectangular cross-section and forming device technology, which is applied in wood compression, wood processing equipment, reed/straw treatment, etc., can solve the problems of large differences in bamboo size and bamboo size, and achieve easy industrial amplification, good effect, and improved utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

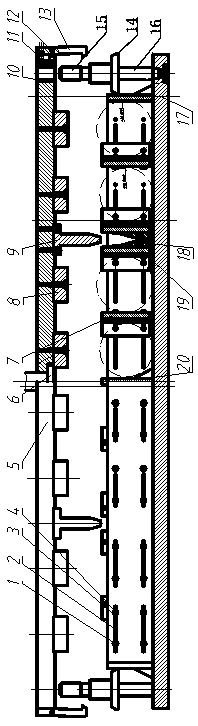

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments.

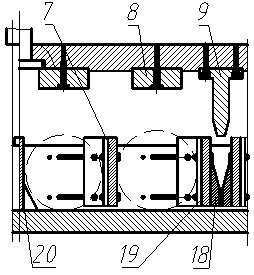

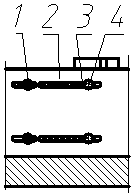

[0030] The rectangular-section bamboo molding device is characterized in that it includes several molding units arranged side by side, and each molding unit includes an upper mold structure and a lower mold structure;

[0031] The upper mold structure includes a pressing plate 5, the central position of the lower surface of the pressing plate 5 is provided with a vertically downward part upper wedge 9, and two pressing parts are arranged on both sides of the part upper wedge 9. Block 8, the lower mold structure includes a bottom plate 17, two parts lower wedges 18 are arranged at the central position of the bottom plate 17, and the two parts lower wedges 18 are arranged oppositely, and the outer parts of each part lower wedge 18 The sides are all fixedly installed on the side walls of the powered movable plate 19, the left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com