Winding tube cutting apparatus and method

A cutting device and winding tube technology, which is applied to sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of strip winding tubes with thicker steel strips that cannot be cut.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

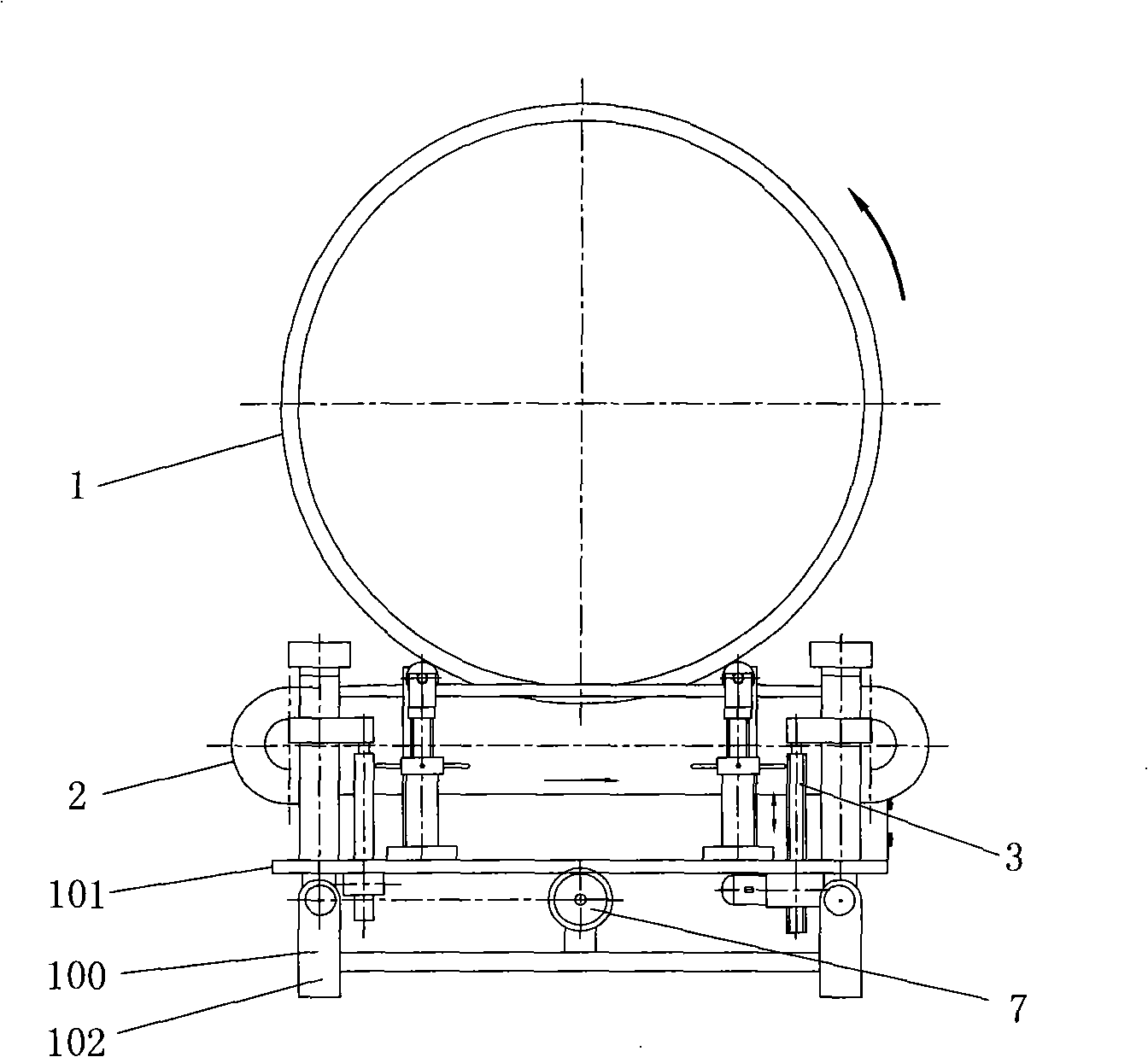

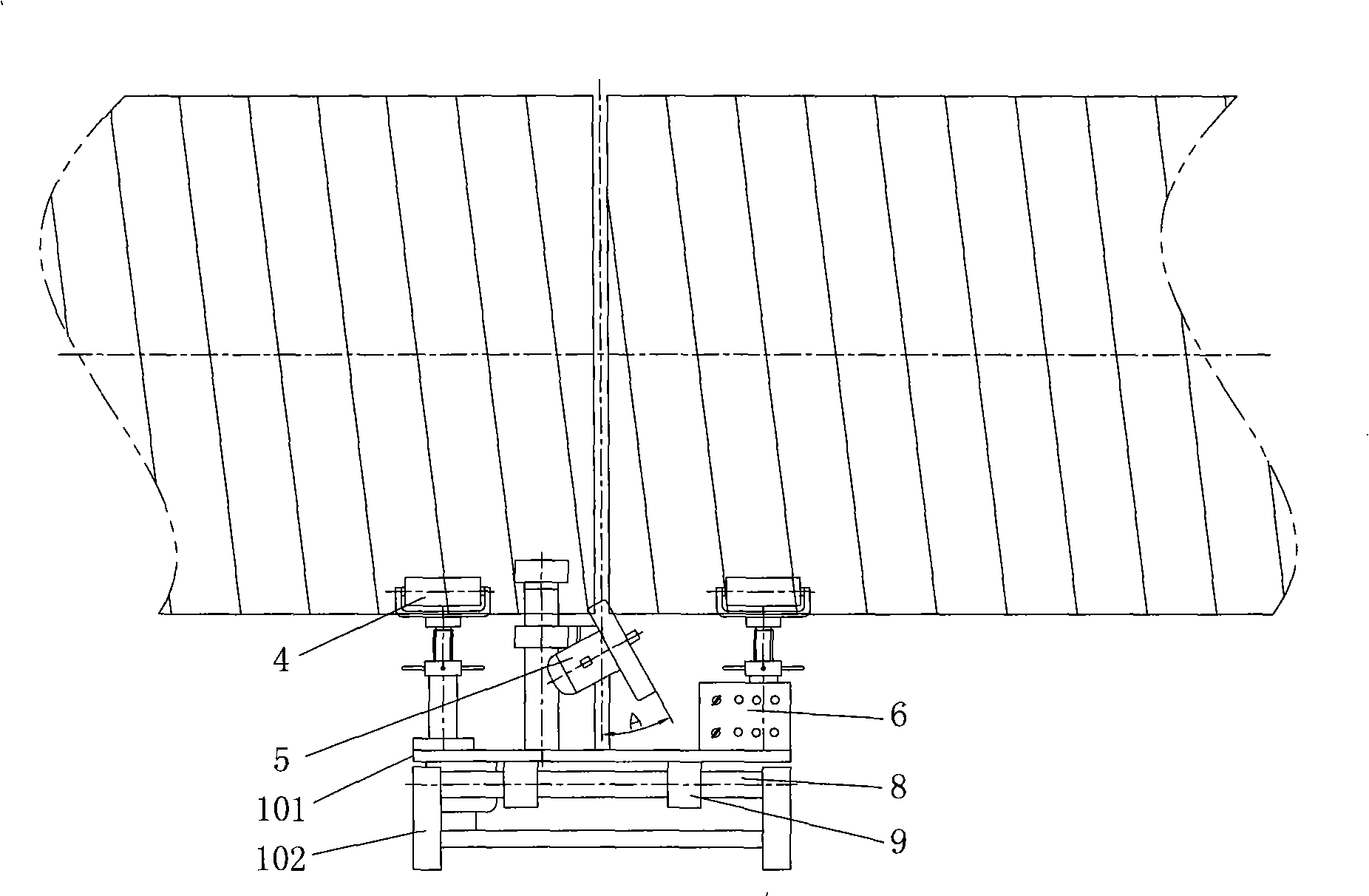

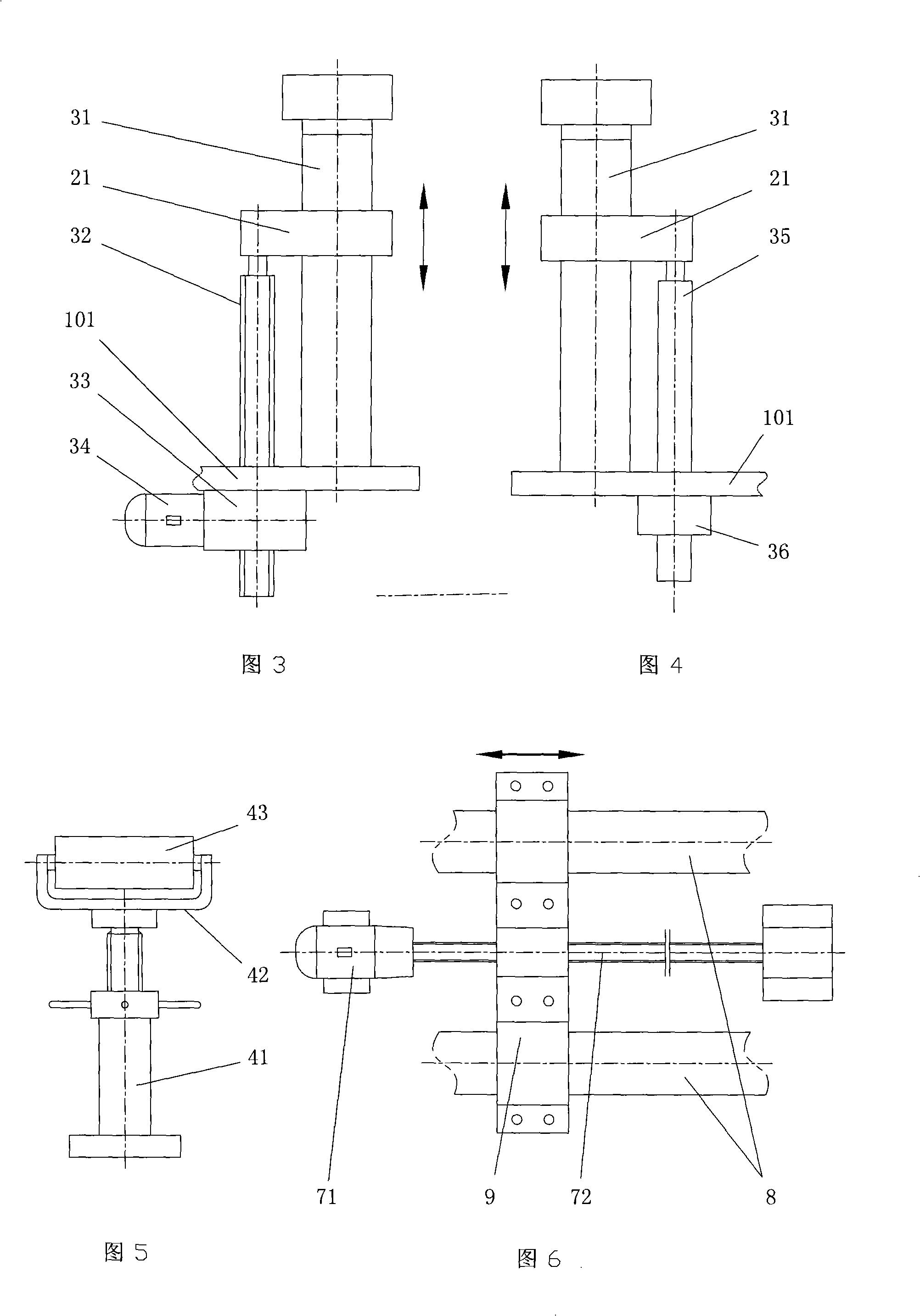

[0033] Such as figure 1 , figure 2 As shown, the winding pipe cutting device of the present invention includes a frame 100, a winding pipe support frame 4, a cutting device 5, and a moving device 7. The frame 100 includes a fixed frame 102 and a movable frame slidably connected to the fixed frame 102 along the axis of the winding pipe. The winding pipe support frame 4 is connected to the moving frame 101 along the axis of the winding pipe to support the winding pipe 1. The cutting device 5 is connected to the moving frame 101, and the moving device 7 is connected to the fixed frame 102 and the moving frame 101, respectively. The device 7 drives the relative moving speed of the moving frame 101 and the fixed frame 102 to be equal to the moving speed of the winding tube 1 along its own axial direction, that is, ensuring that the moving frame 101 and the winding tube 1 move synchronously along the axial direction of the winding tube 1.

[0034] The cutting device 5 includes a band s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com