High cutting force medical water jet scalpel and application thereof

A cutting force, medical technology, applied in the field of medical devices, to achieve the effect of wide use, reduce adverse reactions, and increase rapid healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

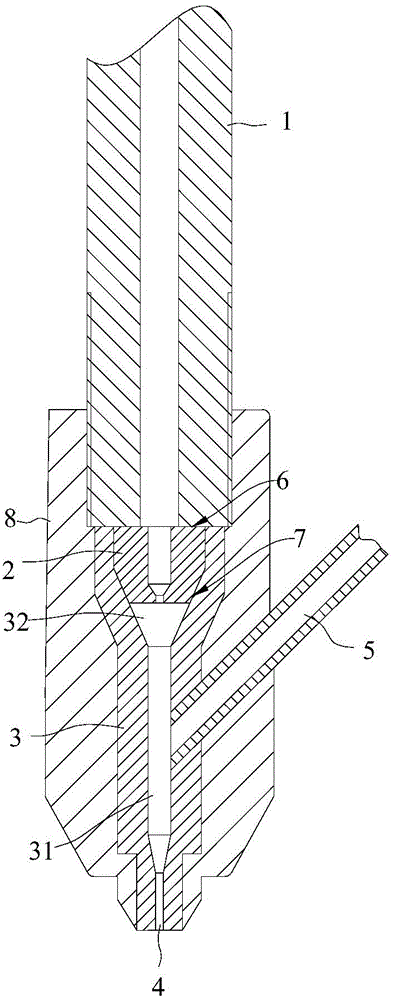

[0016] refer to figure 1 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 1 The structure shown is a reference description, but the actual application direction of the present invention is not limited thereto.

[0017] The present invention provides a high-cutting-force medical waterjet, which is used for cutting biological tissues, comprising a high-pressure pipe 1, a liquid nozzle 2 and a mixing pipe 3 connected in sequence, and the mixing pipe 3 is at an end away from the liquid nozzle 2 The aperture shrinks to form a mixing nozzle 4 which coincides with the axis of the liquid nozzle 2 . The mixing tube 3 forms a mixing chamber 31 between the liquid nozzle 2 and the mixing nozzle 4, and the side wall of the mixing cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com