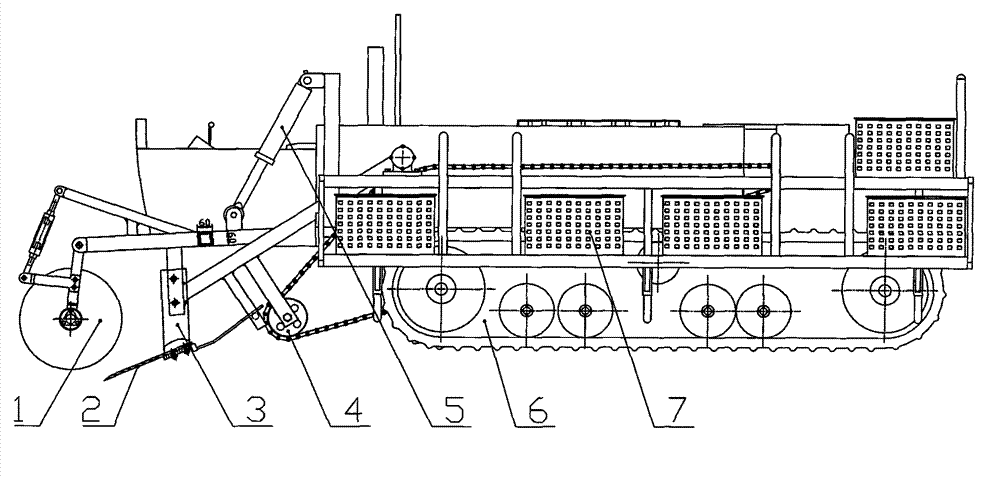

Small crawler type tuber combine harvester

A combine harvester and crawler-type technology, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of unfavorable use of small plots and large volumes, and achieve miniaturization and compactness. High safety factor , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

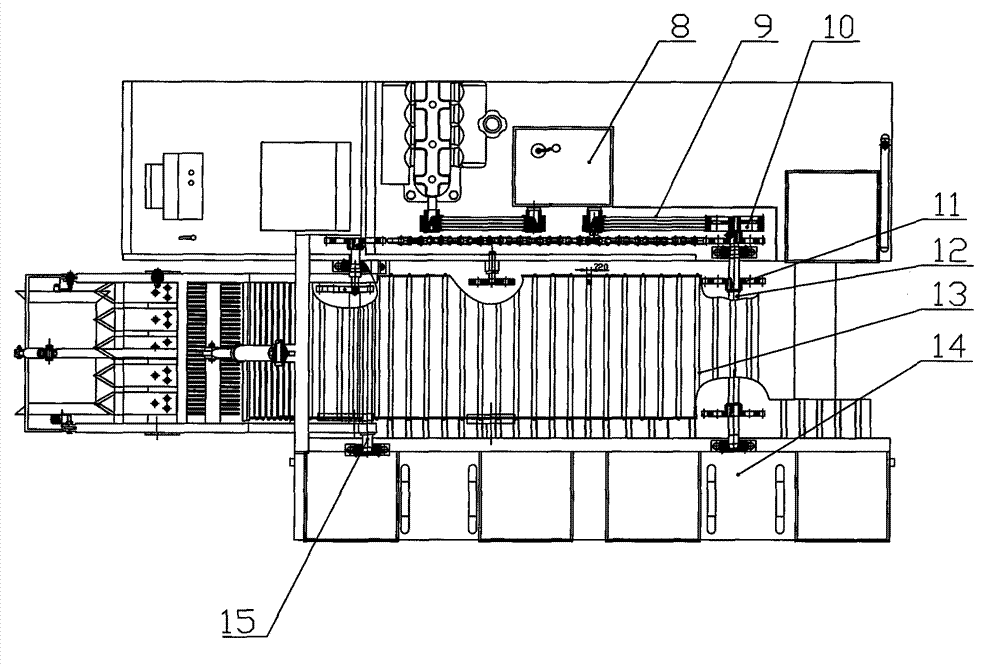

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] The small crawler-type potato combine harvester includes a power traveling mechanism, and the power traveling mechanism is provided with an excavation structure and a conveying and cleaning mechanism. The excavating mechanism is located in front of the conveying and cleaning mechanism and is fixedly connected to the conveying and cleaning mechanism . Described power walking mechanism comprises crawler-type walking chassis 6, and described crawler-type walking chassis 6 is provided with gearbox 8, and described gearbox 8 is connected with pulley 10 by belt 9, and described pulley 10 is connected with drive wheel 11 and The drive shaft 12 is connected. The conveying and cleaning mechanism includes a conveying device, a support wheel 4 and an intermediate shaft 15, the supporting wheel 4 and the intermediate shaft 15 carry a conveying device, and the conveying dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com