Peanut combine harvester

A combined harvester and peanut technology, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of increasing difficulty in drying and shelling processing, increasing transportation and processing costs, reducing device picking rates, and achieving power transmission. High efficiency and reliability, increase the reliability of the mechanism, and the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

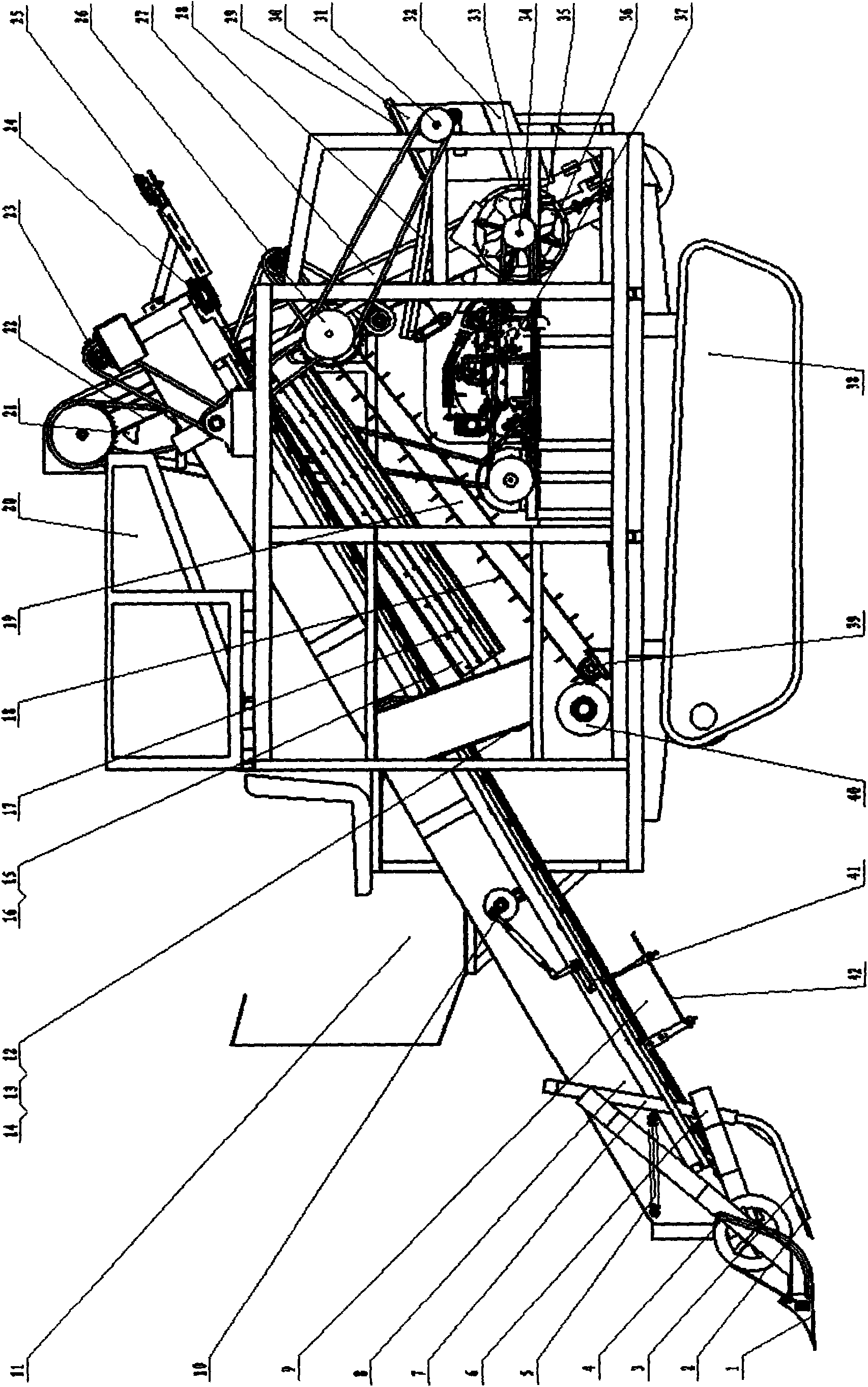

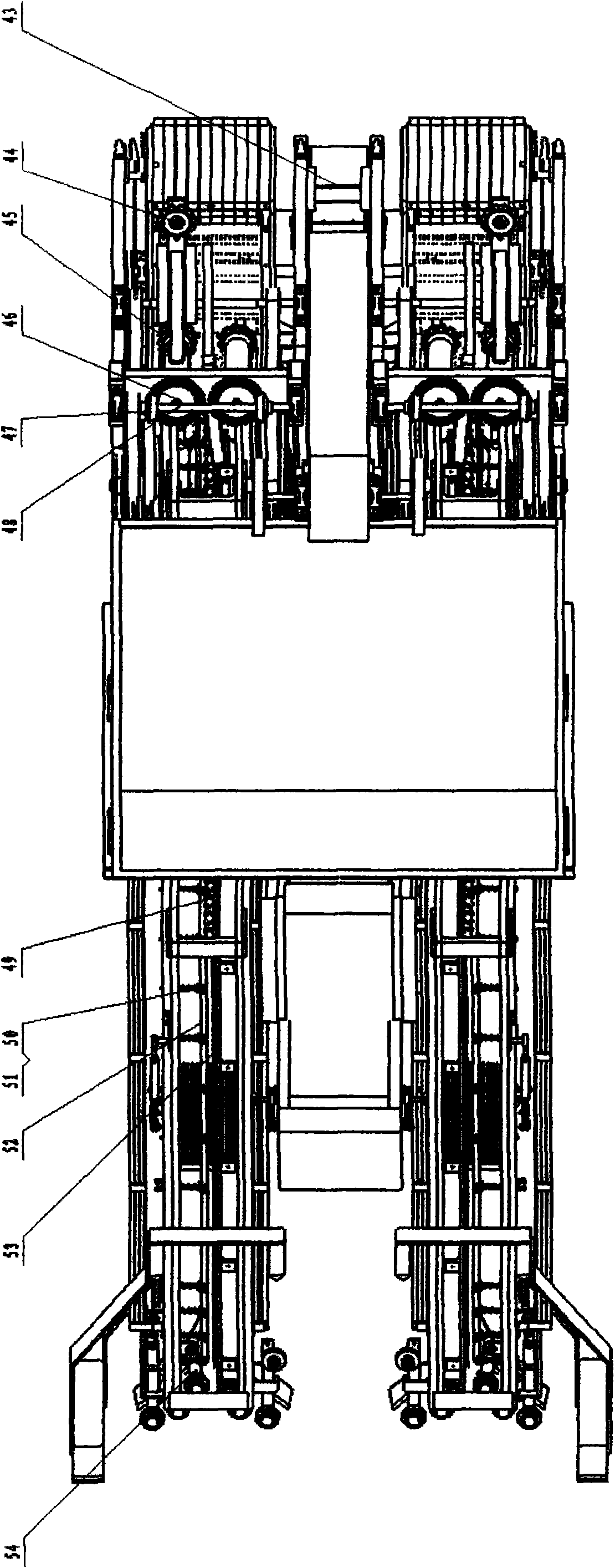

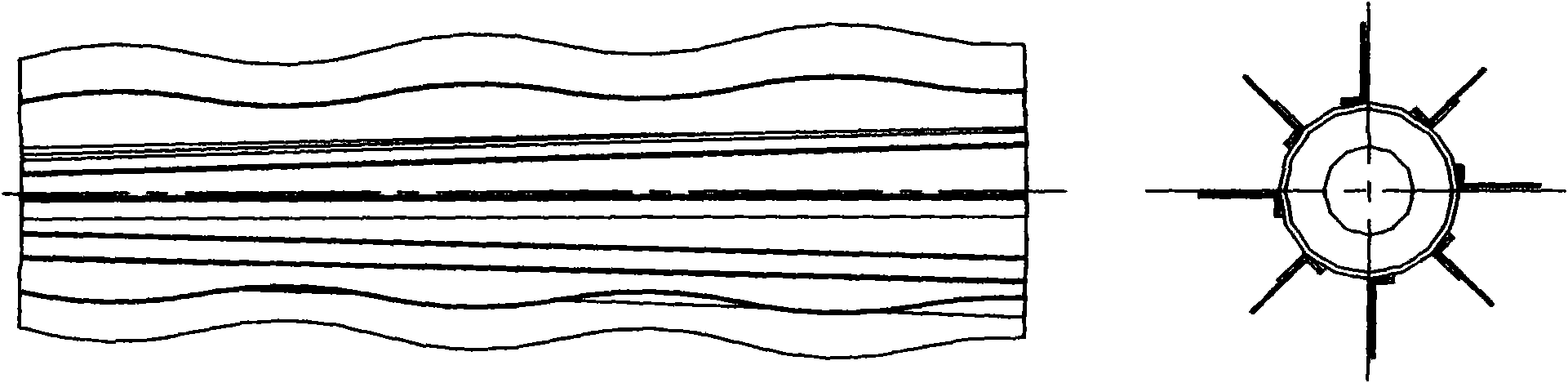

[0017] A peanut combine harvester, the body is provided with a power walking mechanism, an excavating mechanism 6, a clamping and conveying mechanism, a fruit picking mechanism 17, a cleaning mechanism 30, and a lifting storage mechanism 27, and the lower part of the body is provided with a power walking mechanism. Mechanism, the upper part of the body is provided with a clamping and conveying mechanism, the front end of the clamping and conveying mechanism is provided with an excavating mechanism 6, the lower part of the clamping and conveying mechanism is provided with a soil-beating mechanism 9 and a fruit picking mechanism 17 in sequence, and the rear of the clamping and conveying mechanism The part is provided with cleaning mechanism 30, and one side of the body is provided with lifting storage mechanism 27; The power input shaft of described gripping conveying mechanism, fruit picking mechanism 17, cleaning mechanism 30 links to each other with power mechanism 37 through p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com