Automatic walking wheel type rice straw gathering bundler

A rice straw and baler technology, which is applied to the field of agricultural machinery, can solve the problems of easy heating of rice straw, poor flexibility, low operation efficiency, etc., and achieve the effects of reducing labor input and energy consumption, compact structure design, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

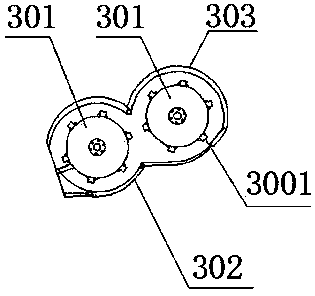

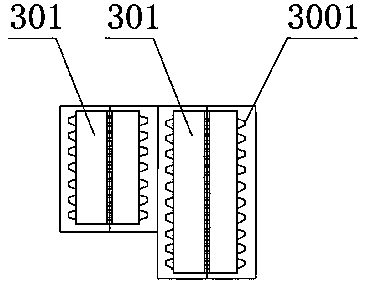

[0025] like figure 1 , figure 2 and image 3 As shown, a self-propelled wheeled rice straw picking and baling machine includes a straw picking and conveying system, a straw compressing and baling system, and a power walking system. The straw picking and conveying system includes a straw picking device 1 , an inclined straw conveying device 2 and a roller type straw conveying device 3 . The straw pick-up device 1 is composed of a sliding roller 101, spring teeth 102, a pipe shaft 103, a driving disc 104, a feeding auger device 105, a copy wheel 106, a pick-up device spindle 108, a casing 109, and a drum guard plate 1012; drum type straw The conveying device 3 is composed of a toothed bar type conveying roller 301, a smooth concave plate 302 and a roller top cover 303. The toothed bar type conveying roller 301 is located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com