Electric goods taking trolley

An electric and cargo platform technology, applied in the direction of lifting devices, can solve the problems of inconvenient handling of large items, workers falling, and being unable to use, so as to improve operability and convenience, reduce collision loss, and increase safety distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

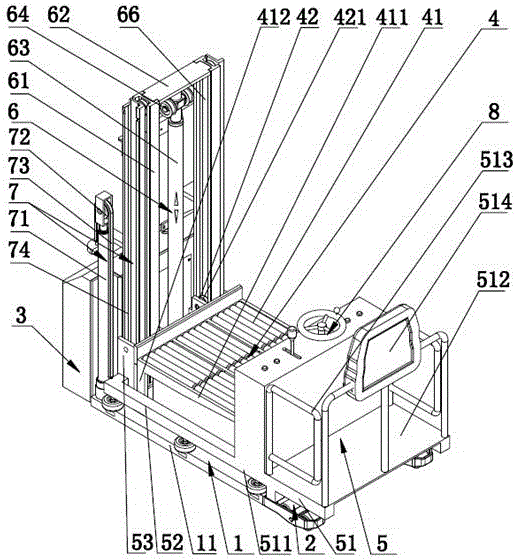

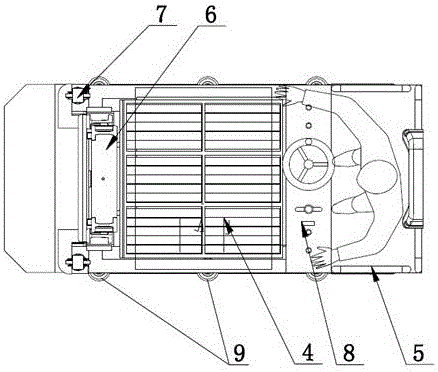

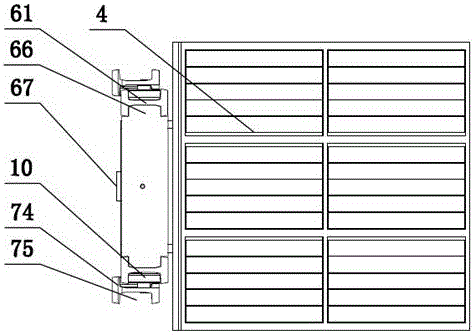

[0029] An electric pick-up cart disclosed by the present invention, as attached figure 1 - attached figure 2 Shown, comprise support chassis 1, the shape and the structure of described support chassis 1 can be the shape and the structure of existing various feasible automobile chassis, do not repeat them here; Described support chassis 1 is provided with protruding from described The guide wheel set 9 supporting the poles 11 on both sides in the long side direction of the chassis 1, the guide wheel set 9 can effectively buffer the collision between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com