Crawler self walking type garlic harvesting machine

A self-propelled harvester technology, applied to digging harvesters, harvesters, excavators, etc., can solve the problems of garlic damage, increased difficulty in sorting and selection, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

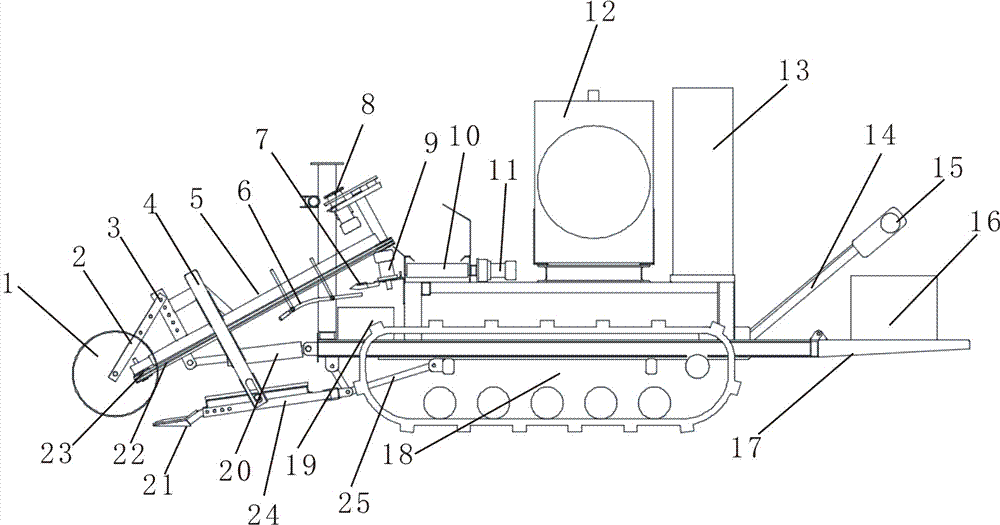

[0022] Now refer to the attached figure 1 , combined with the embodiment description as follows: The crawler self-propelled garlic harvester includes a clamping transmission cutting part, a digging part, a power walking part, and a transmission, transportation and collection part. The clamping, conveying and cutting part is the main working unit of the crawler self-propelled garlic harvester of the present invention, and a power walking part is connected behind the clamping, conveying and cutting part, and the power walking part is controlled by the vehicle chassis and driving system, fuel tank 13, engine 12 and crawler belt running mechanism 18. The power running mechanism described here adopts the mature technology of existing agricultural machinery to ensure the running and control of the equipment. The vehicle chassis of the power running part is provided with a transmission Shipping collection part.

[0023] The clamping and conveying cutting part includes header 5, clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com