Discharging device of belt conveyor

A belt conveyor and unloading device technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of uneven unloading, wear of the belt surface of the belt conveyor, uneven friction between the scraper and the belt surface, etc., and achieve unloading Thoroughly, the effect of improving the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

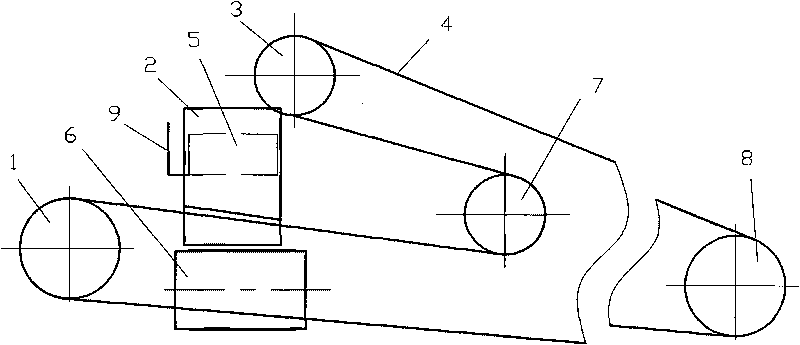

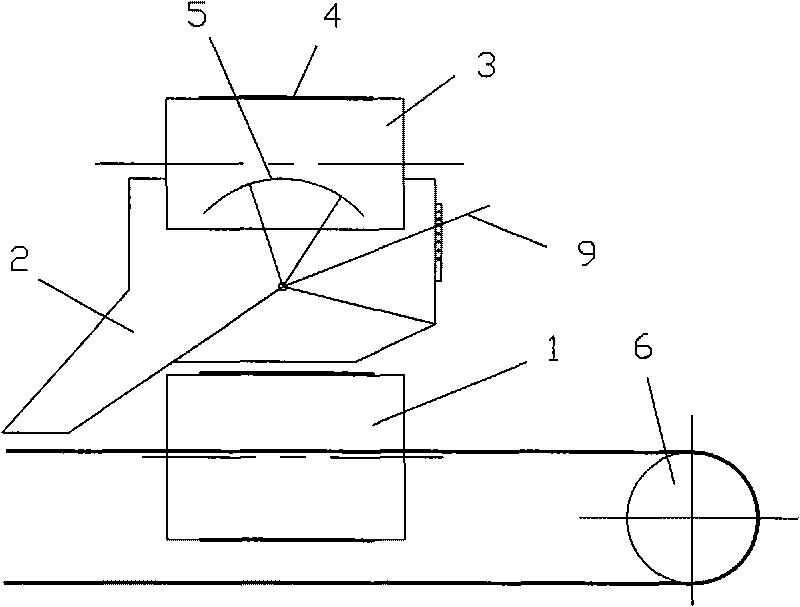

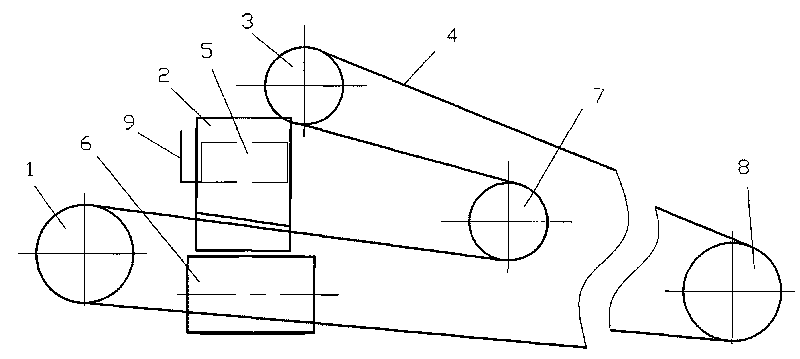

[0009] As shown in the drawings, it includes stockyard drum 8, discharge drum 3, reversing drum 7, drum 1 of belt conveyor one, belt conveyor two 6, discharge funnel 2, movable material distribution plate 5 and belt 4. The unloading drum 3, the reversing drum 7, and the drum 1 of the belt conveyor 1 are distributed in a triangle, the unloading drum 3 is on the top, and the belt 4 sequentially passes from the stockyard drum 8, the unloading drum 3, the reversing drum 7, and the belt conveyor 1. Drum 1 is bypassed, and the belt 4 between the stockyard drum 8 and the unloading drum 3 is a climbing section, which can raise the material level to facilitate unloading and material distribution. Belt 4 is a material distribution conveyor belt. There is a discharge funnel 2 on the lower left of the discharge drum 3, and there is a movable material distribution plate 5 at the entrance of the discharge funnel 2. The movable material distribution plate 5 is hinged with the discharge funne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com