Tea fixation and stripping method

A technology for clearing green strips and tea leaves, which is applied in the direction of tea treatment before extraction, which can solve problems such as poor efficiency and effect of clearing green strips, uneven cloth, etc., and achieve the effect of improving effect and efficiency, improving efficiency and effect, and concise steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the embodiment of the present invention, a method for finishing tea leaves is proposed. When the tea leaves are finished in the trough, the tea leaves to be finished are evenly distributed on the cloth mechanism on the upper side of the trough, and the trough After the inner tea strips are finished and removed and reset, start the distribution mechanism and put the tea evenly distributed on the distribution mechanism directly into the bottom slots, and then the slots will be stripped again and evenly distributed in the distribution mechanism The tea leaves that are ready to be finished are repeated in this way until all the tea leaves are finished.

[0035] In the method of the present invention, firstly, when the tea strips are finished in the strip trough, the tea leaves to be finished are evenly distributed on the cloth mechanism on the upper side of the strip trough. The mechanism puts the uniformly distributed tea leaves on the cloth mechanism directly into the ...

Embodiment 2

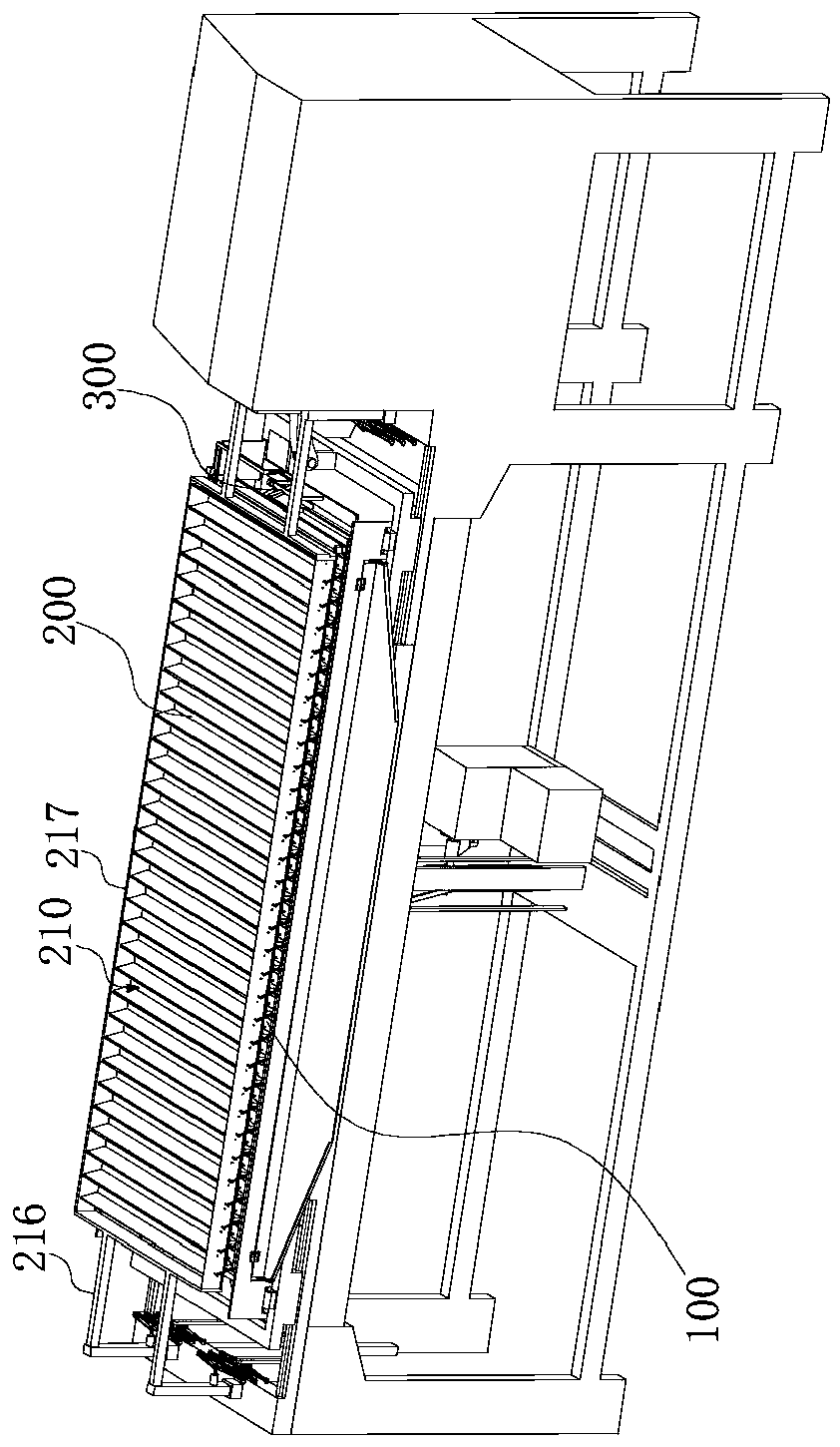

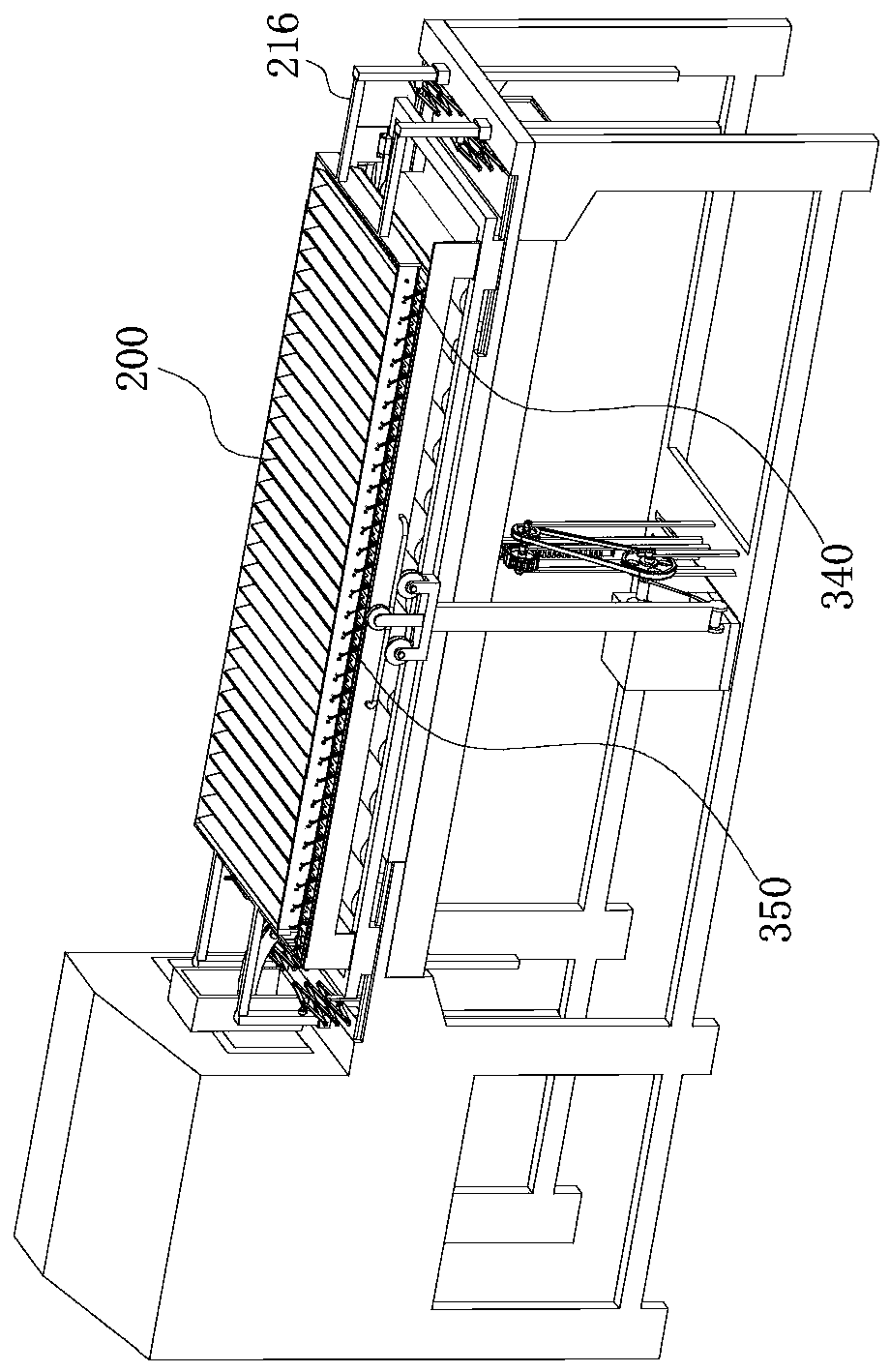

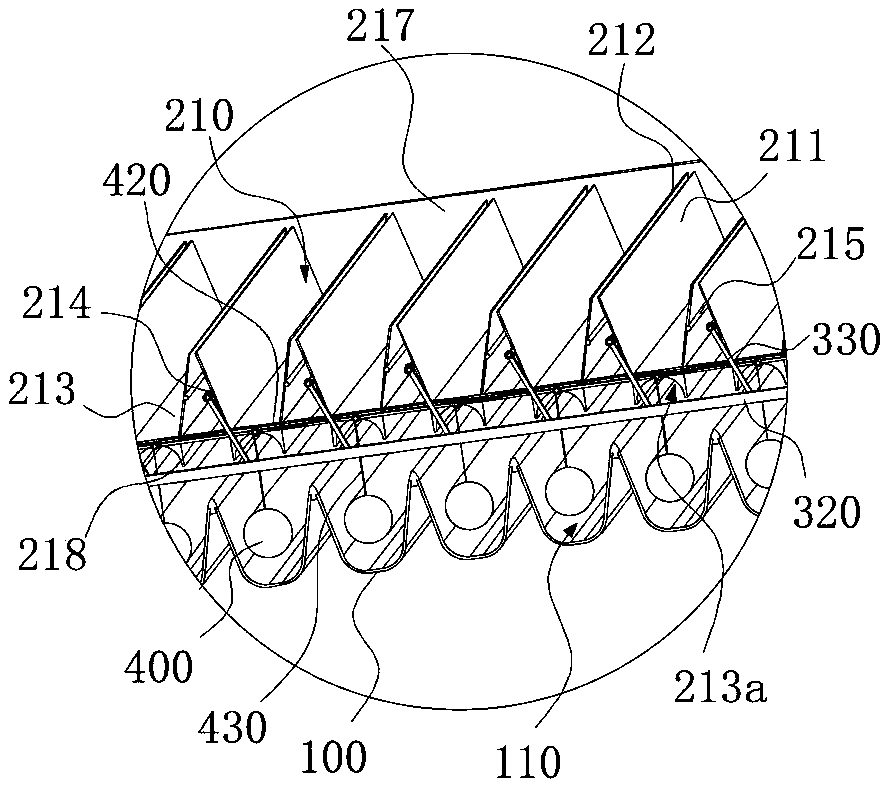

[0056] refer to Figure 1-4 , according to a kind of method for finishing tea leaves proposed by the present invention, in the embodiment of the present invention, a kind of tea stripping machine is proposed, comprising a slot pan 100 composed of various strip slots 110, the top of the slot pan 100 is provided with Distributing device 200, distributing device 200 comprises the distributing trough 210 that is used to hold material correspondingly arranged with each strip trough 110 respectively, and the distribution trough 210 is connected with the adjustment mechanism 300, and the adjustment mechanism 300 is used for adjusting the distribution chute 210 to the strip arrangement chute. 110 inner fabric.

[0057] The tank pot 100 is used for finishing and organizing the tea leaves. Through the setting of the distributing device 200, the function of distributing materials to each of the organizing tanks 110 in the tank pot 100 is realized. Each distributing trough 210 can distri...

Embodiment 3

[0084] refer to Figure 2-7 , according to a kind of method and embodiment 2 of the present invention to fix the green tea leaves, in the embodiment of the present invention, a kind of adjustment mechanism for adjusting the distribution trough on the tea leaf machine to add fresh tea leaves is proposed, including a horizontally moving Push rod 310 and push sleeve 360, the middle part of push rod 310 is connected with each distributing groove bottom 213, the other end of push rod 310 is installed with push sleeve 360, and push sleeve 360 is slidably installed on push rod 310, and push sleeve 360 slide stroke The two ends of the push sleeve 360 and the push rod 310 are respectively provided with stoppers 363 for preventing the separation of the push sleeve 360 and the push rod 310, and the push sleeve 360 is also provided with an elastic member 380, and the elastic member 380 and the push rod 310 are respectively placed at the two ends of the push sleeve 360; The A1 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com