System and method for powder transportation

A transportation method and technology of transportation system, applied in the field of material transportation, can solve the problems of affecting the loading speed, high cost of human resources, harsh working environment, etc., so as to reduce the staff and workload, prevent the problem of loose sealing, and improve the market. The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

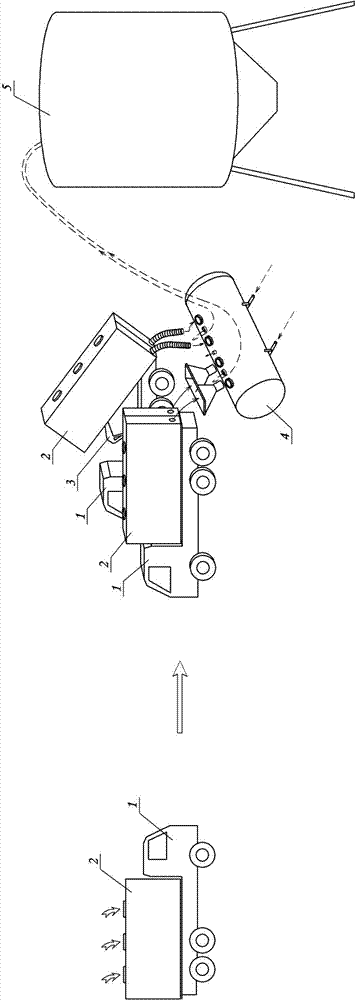

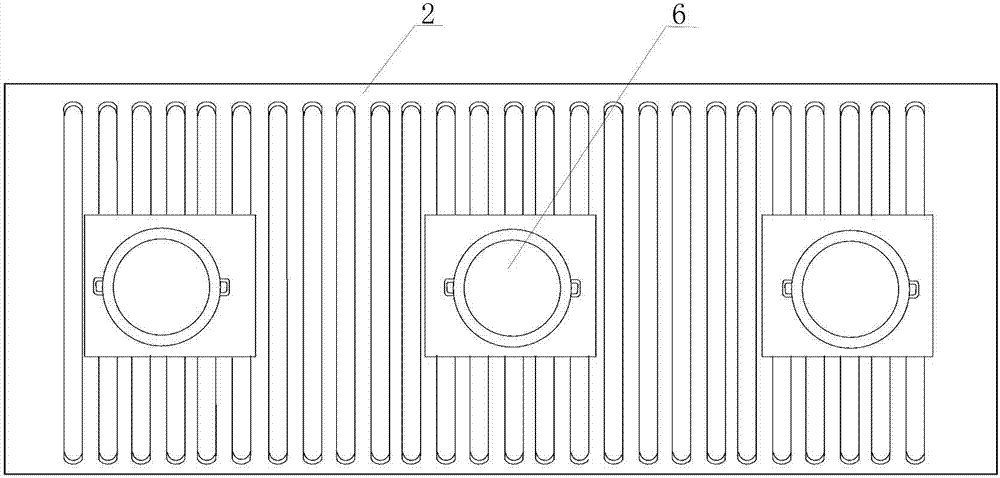

[0019] Example 1: A powder transportation method, see figure 1 , Use international standard containers to transform international general containers, such as Figure 2 ~ Figure 5 As shown, the modified structure is relatively simple, but it is suitable for powder loading and unloading, and the effect is significant. The top of the transformed container is provided with a feed port 6 and a sealing cover, and the bottom of the rear door at the rear end of the container 2 is provided with a discharge port 8, and a pushing mechanism 3 capable of turning the container 2 is also provided. Load the powder without pressure through the feed port at the origin, and then seal the feed port. Use containers as a multimodal transportation tool to transport powder to the destination. It can be installed on the car body 1 together, and the whole process can be completed only by the driver alone, and the shipping speed is very fast. Discharge naturally through the discharge port 8 at the dest...

Embodiment 2

[0020] Example 2: see figure 1 , The content is basically the same as that of Example 1. On the basis of Example 1, pipes or combined funnels can also be used as auxiliary tools, especially when the car body 1 is not moved in place or the container outlet and fluidized bed feed tank When the inlets are not aligned, pipes are used to connect the container outlet and the inlet of the fluidized bed feed tank, so that the powder will slide down the funnel into the fluidized bed feed tank under its own gravity.

Embodiment 3

[0021] Example 3: See figure 1 , Figure 8 with Picture 9 The content is basically the same as that of Example 1. On the basis of Example 1, the combined funnel is used to connect the container discharge port and the fluidized bed feed tank inlet, so that the powder will slide down the funnel to the fluidized bed under its own gravity. Inside the tank. Conjoined funnel see Figure 8 with Picture 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com