Concentric bidirectional-rotation feed stirring machine

A two-way rotation, mixer technology, applied in mixer accessories, mixers with rotating containers, mixers and other directions, can solve the problems of low mixing efficiency, incomplete discharge, and layered feed mixing, and achieves simple structure and feeding. Convenience and complete discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

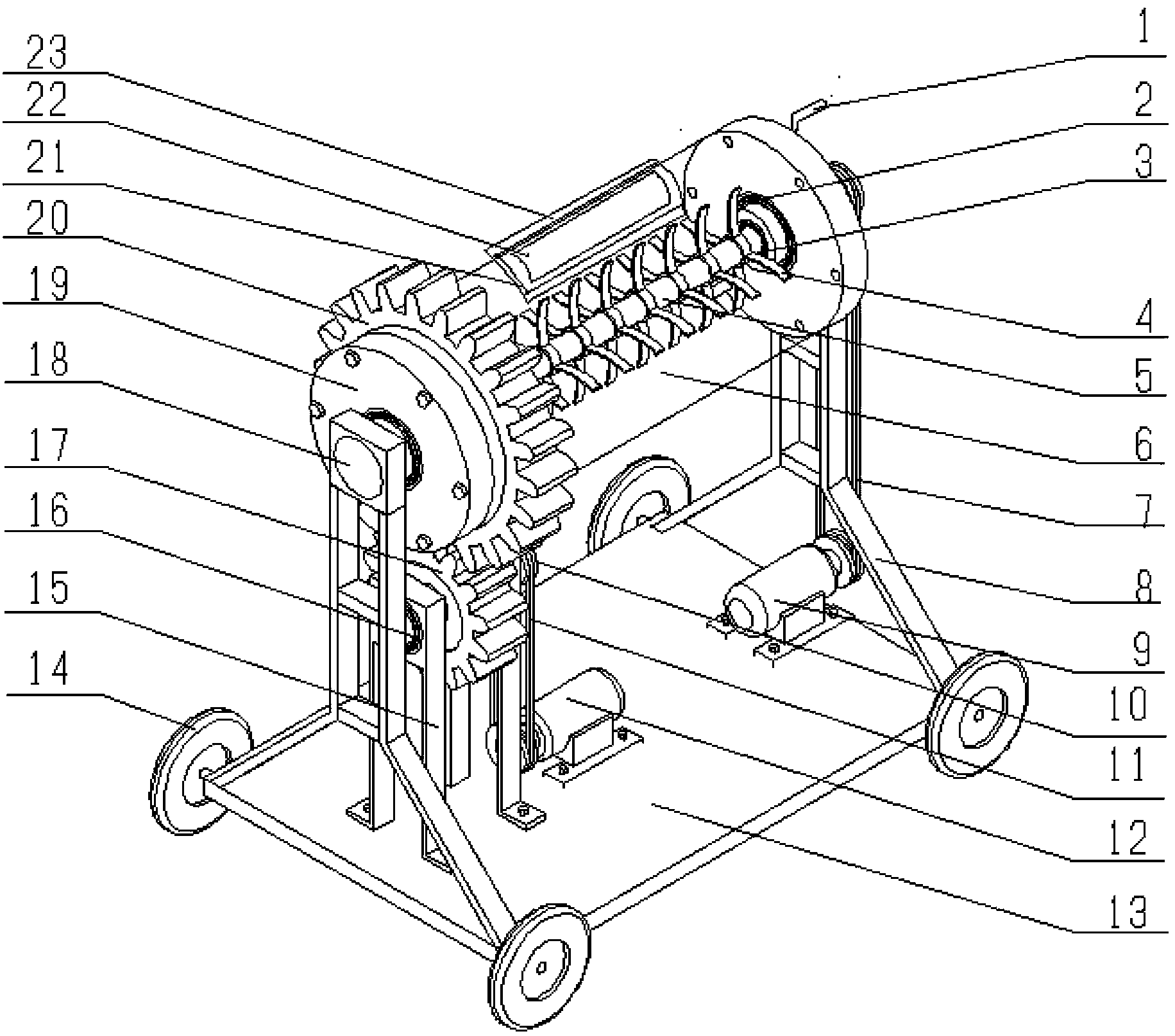

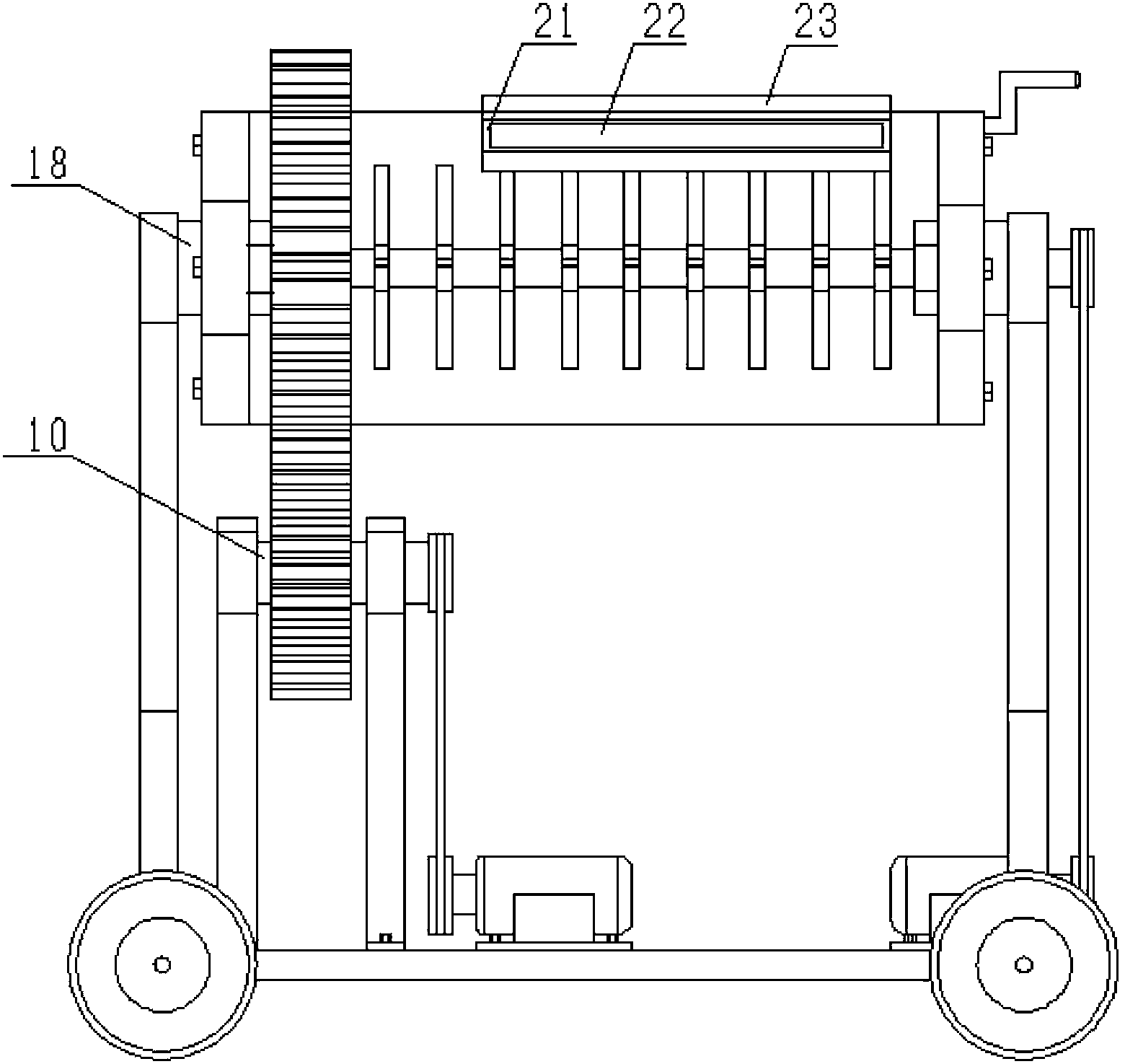

[0020] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a coaxial two-way rotating feed mixer, including a mixing shaft 5 in the mixing drum 6, the mixing drum 6 is set on the support shaft 18 through the large bearing 2, and the mixing drum 6 is provided with a mixing drum on both sides The end cover 19; the stirring shaft 5 is driven by the motor I9 through the transmission belt I7, and the stirring shaft 5 is set on the supporting shaft 18 through the small bearing 3; The gear transmission shaft 10 is fixedly connected, driven by the motor II 12 through the transmission belt II 11 , and the gear transmission shaft 10 is arranged on the gear transmission shaft supporting frame 15 through the bearing 16 .

[0021] The mixing drum 6 is provided with a feed / discharge port 22, and the feed port and the discharge port share the same port.

[0022] Described feed / discharge port 22 is provided with feed / discharge port cover 21, and feed / discharge por...

Embodiment 2

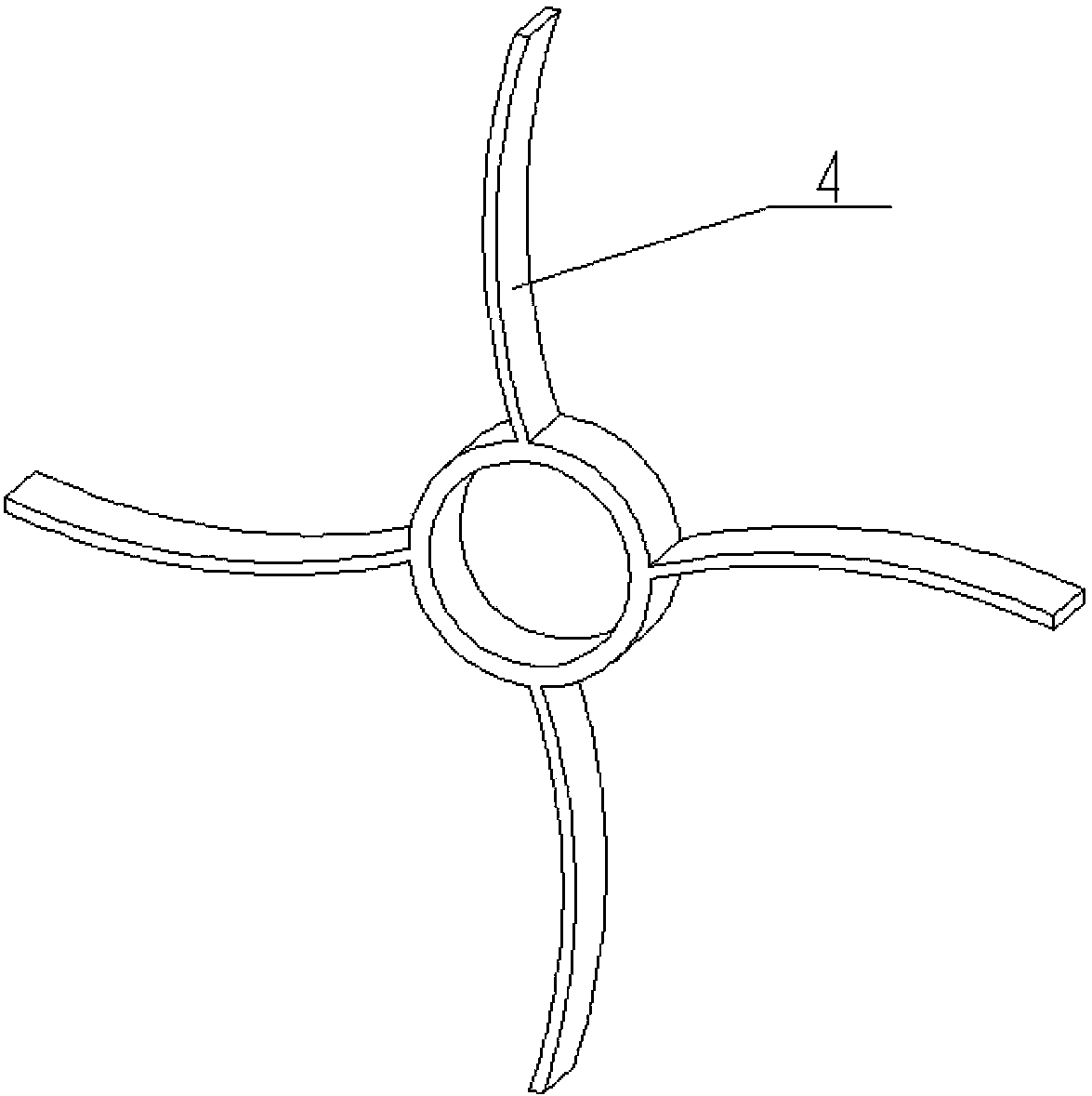

[0026] Embodiment 2: see figure 1 , figure 2 , image 3 , Figure 4 Four arc-shaped blades are welded on the stirring blade 4, the width of each blade is 150-200mm, the large bearing 2, the small bearing 3 and the bearing 16 are roller bearings, and the diameter of the mixing drum 6 is 1.1-1.3m. The optimum ratio of the diameter of the mixing drum 6 to the diameter of the stirring shaft 5 should be 3-4. The overall dimensions of the mixer are about: 4.0-4.5m in length; 1.8-2.0m in width; 1.7-1.9m in height. 6 The capacity is 7-11m 3 , the best amount of feed in the mixing drum 6 is 40%-55% of its capacity, that is, the best filling factor of the mixing drum 6 is 0.40-0.55, and the rotating speed of the stirring shaft 5 should be 2.2-55% of the rotating speed of the mixing drum 6. 2.5 times, the rotating speed of the stirring shaft 5 is 50-60 rpm, the rotating speed of the mixing drum 6 is 20-30 rpm, the stirring time is about 2 minutes, and the unloading time is about 0.5...

Embodiment 3

[0036] Embodiment 3: see Figure 5 , a coaxial two-way rotating feed mixer, basically the same structure as Embodiment 1 and Example 2, the difference is that the middle of the mixing drum 6 is cylindrical, and the two ends are tapered. The volume of the mixing drum makes the discharge more smooth.

[0037] By adopting the above-mentioned embodiment, the concentric two-way rotating feed mixer of the present invention has good mobility, high mixing efficiency, uniform feed mixing, no layering, more convenient feeding, more thorough feeding, reduced labor intensity, and realized farm feed Stirring mechanization and automation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com