Patents

Literature

47results about How to "Unload clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

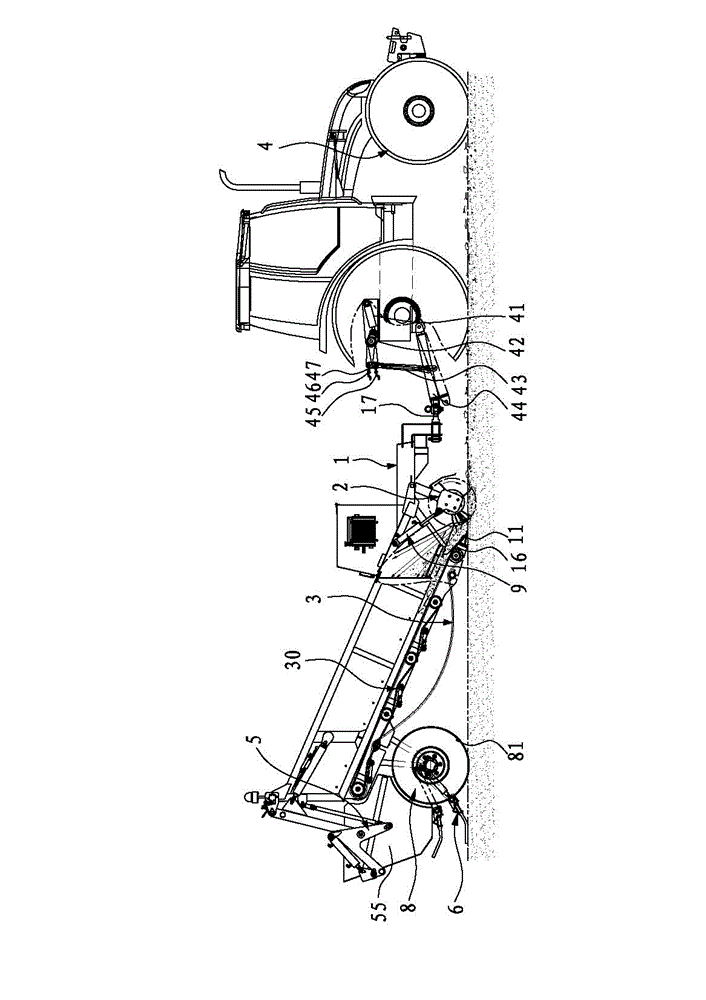

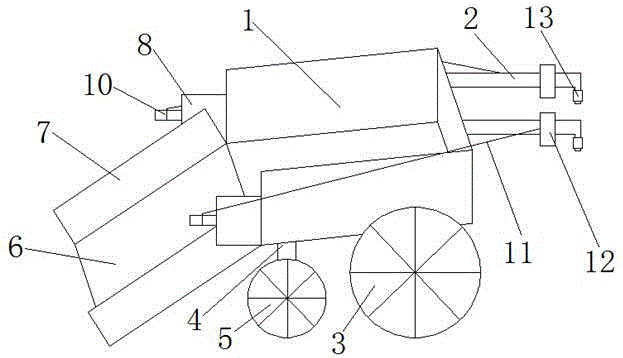

Sand beach cleaning vehicle and cleaning operation method thereof

InactiveCN102747704AReduce weightNot easy to sinkConstructionsCleaning bleachesOperation modeEngineering

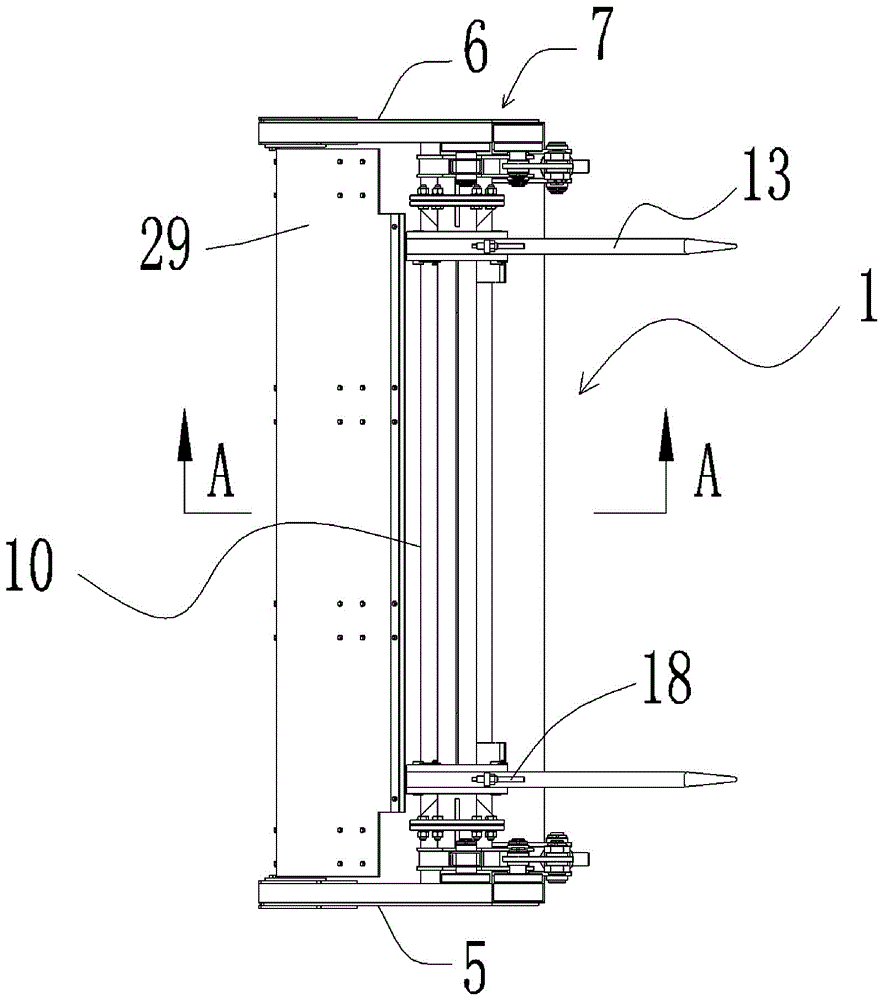

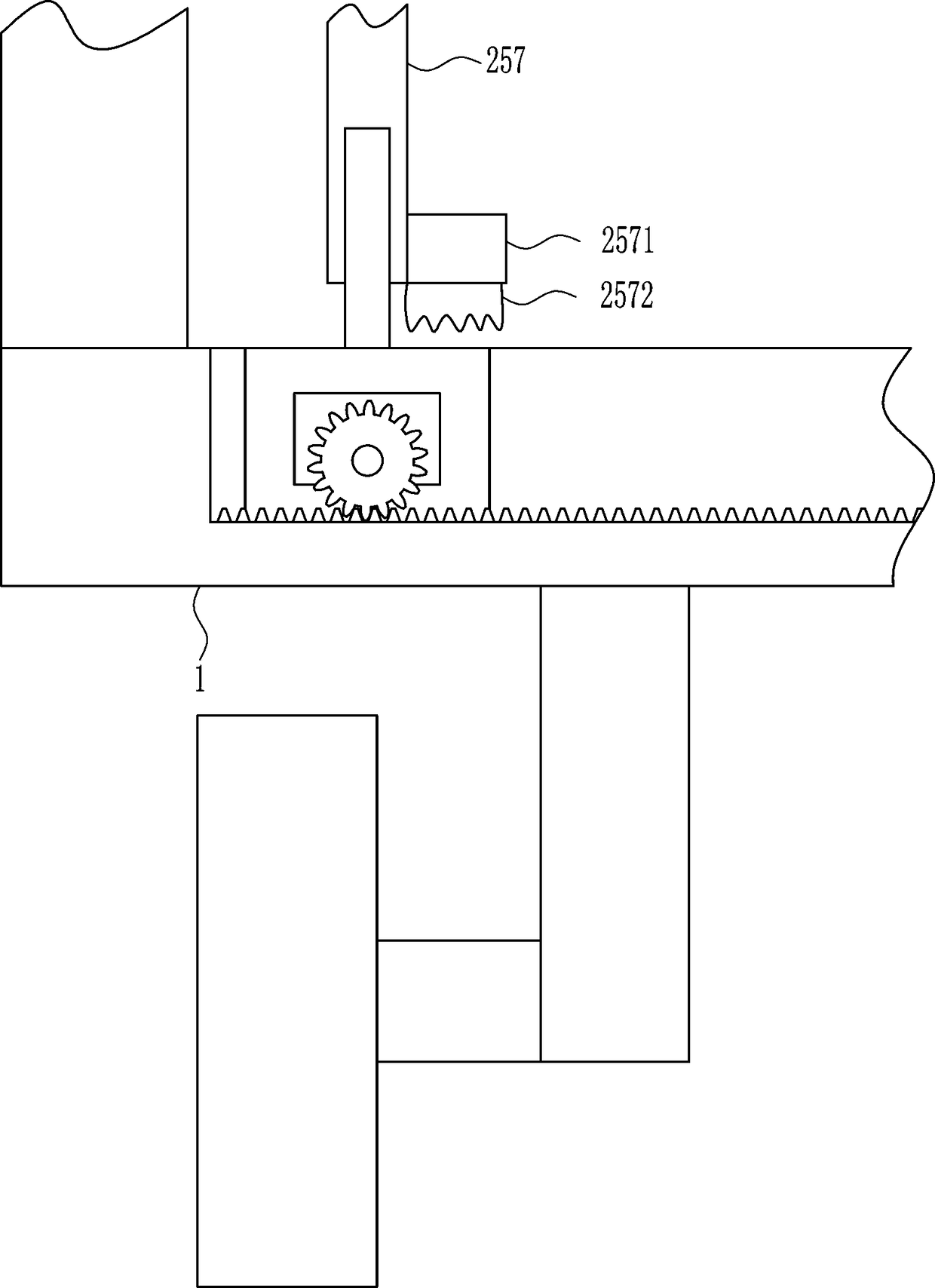

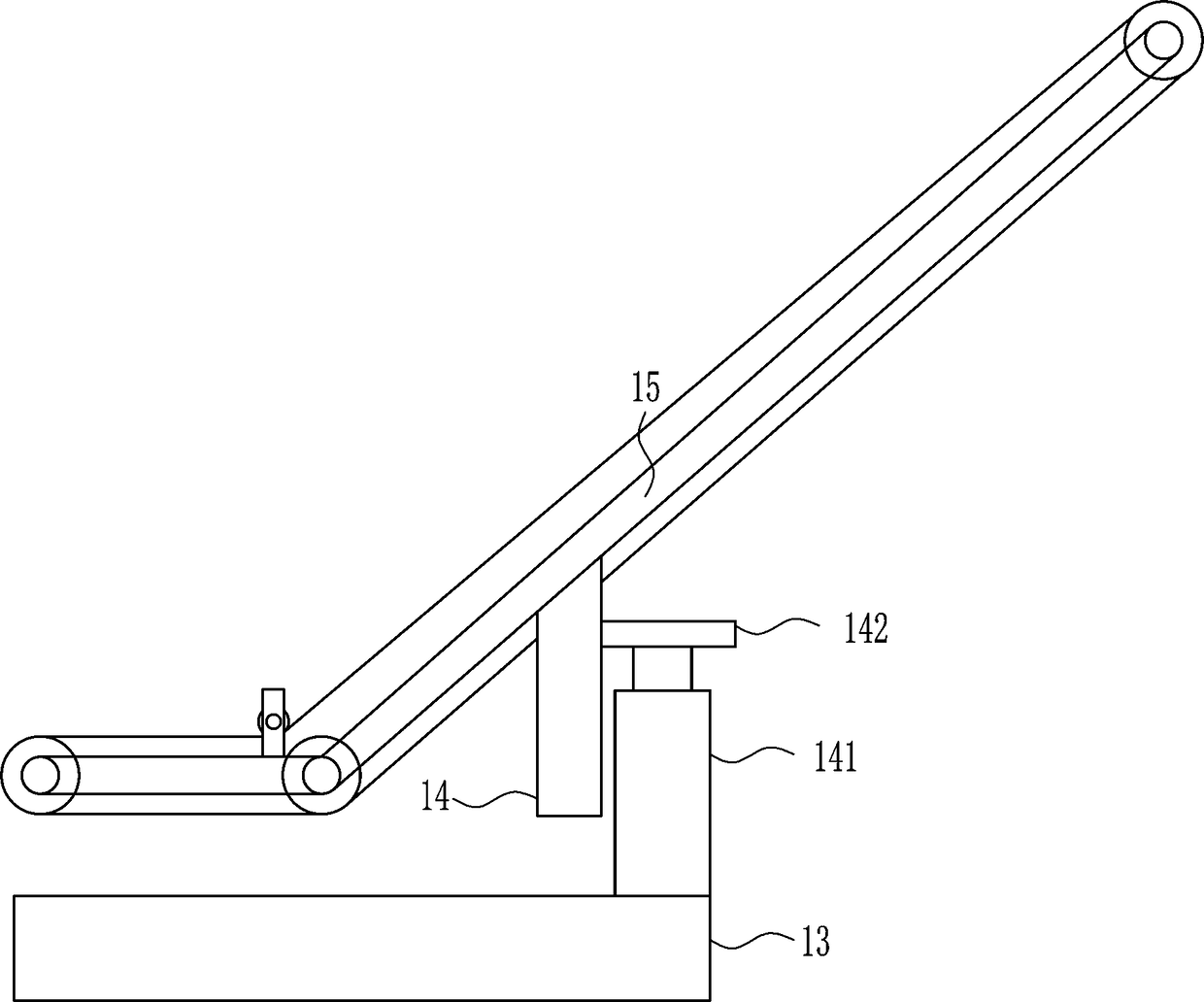

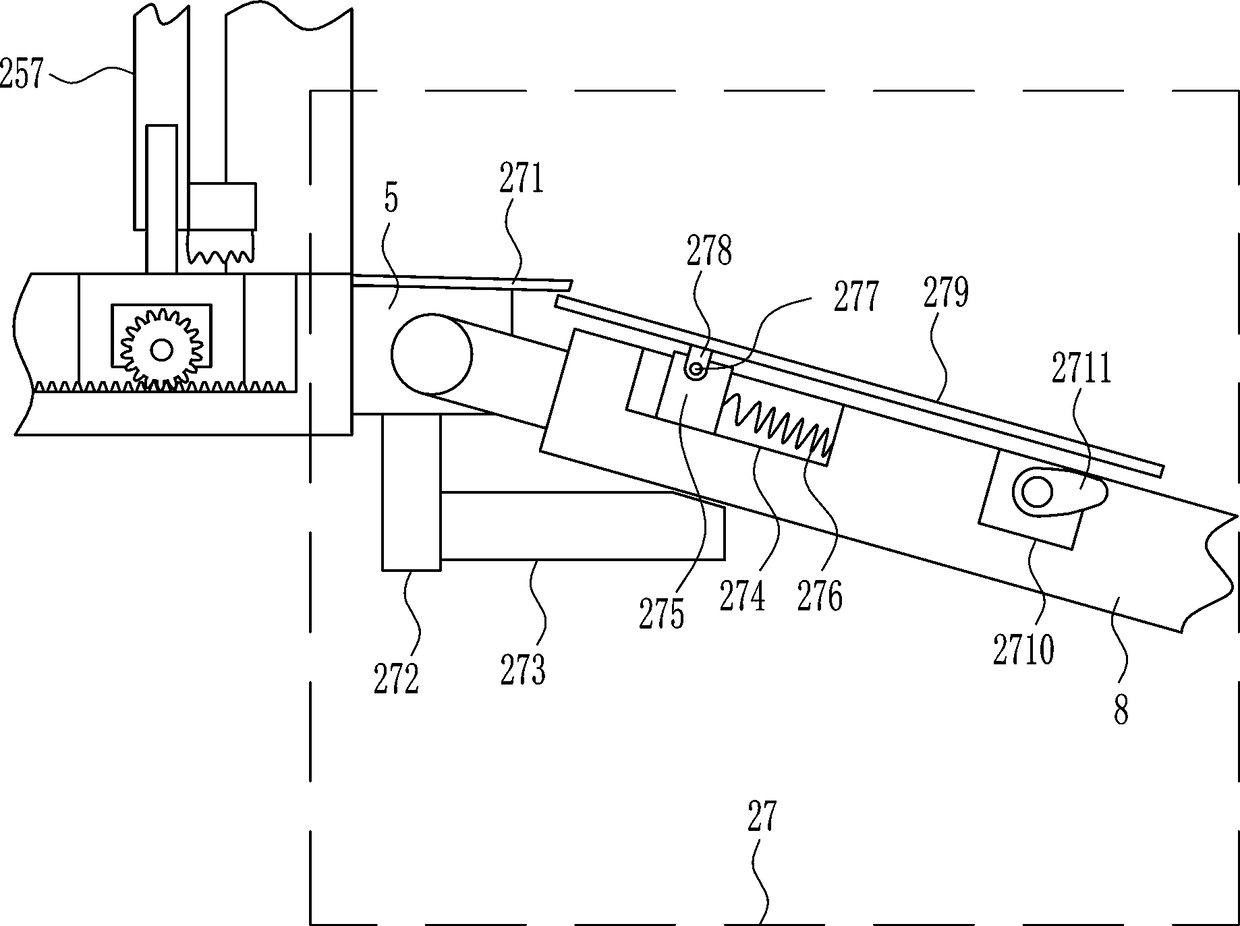

The invention relates to a sand beach cleaning vehicle and a cleaning operation method thereof. The sand beach cleaning vehicle comprises a frame, wherein a sand-stirring idler wheel device is mounted on the front part of the frame; a screening conveying device is mounted on the middle part of the frame; a garbage can and a garbage can lifting turning mechanism are mounted on the rear part of the frame; a push shovel is fixed behind the sand-stirring idler wheel device and on the front lower part of the frame; a sand-guiding plate is fixed on the push shovel; the sand-guiding plate is connected with the screening conveying device; a loading bridge with a wheel is mounted on the rear lower part of the frame; a flattening mechanism which is used for flattening a sand beach is mounted on the loading bridge; a dragging device at the front end of the frame is dragged by a hanging mechanism of a tractor; and the hanging mechanism can control the sand-shoveling depth of the push shovel. When the sand beach cleaning vehicle operates on the dry sand beach, an operation mode of deeply cleaning garbage is adopted; when the sand beach cleaning vehicle operates on the wet sand beach, the operation mode of only cleaning surface garbage is adopted; and during the operation process on the dry and wet sand beaches, the sand beach cleaning vehicle is difficult to sink, has a small running resistance, is high in operation efficiency and can flatten the sand beaches.

Owner:厦门威迪思汽车设计服务有限公司

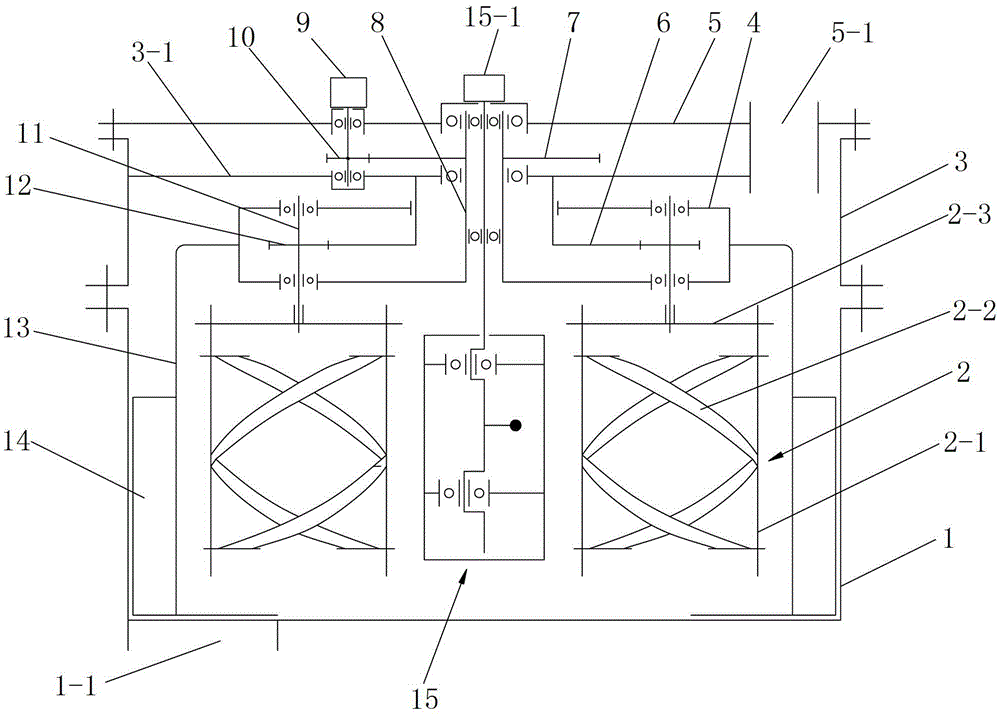

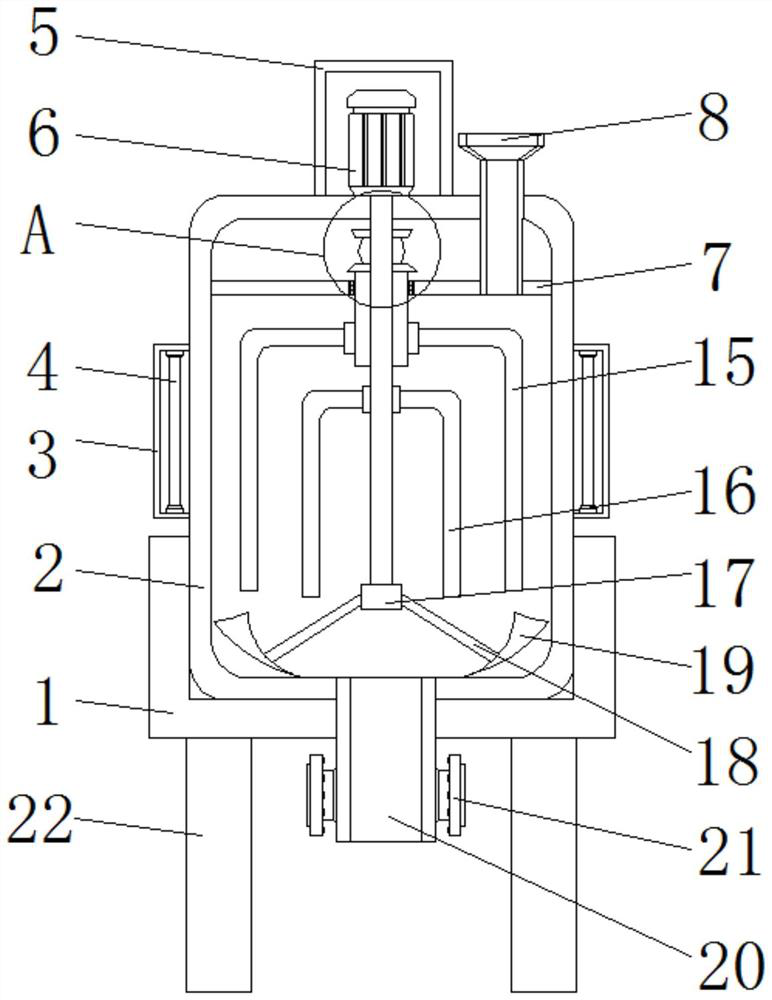

Planetary concrete mixer

InactiveCN102975287ASimple structureNovel and reasonable designCement mixing apparatusGear wheelEpicyclic gearing

The invention discloses a planetary concrete mixer, which comprises a lower barrel body and a plurality of helical ribbon mixing devices, wherein a middle barrel body is connected to the upper part of the lower barrel body; a planetary gear mechanism is arranged in the middle barrel body; a cover plate is arranged at the upper end of the middle barrel body; a mixing drive device is arranged on the cover plate; a mixing input shaft is rotationally connected in the middle of the cover plate; the planetary gear mechanism comprises planetary racks, sun wheels and a plurality of planetary wheels; the planetary racks are connected to the lower end of the mixing input shaft; the sun wheels are sleeved on the mixing input shaft; the upper ends of the sun wheels are connected with the middle barrel body; planetary wheel shafts are arranged on the planetary racks; the planetary wheels are mounted on the planetary wheel shafts; each helical ribbon mixing device comprises two mixing arms; mixing helical ribbons are connected on the inner side surfaces of the two mixing arms; the upper parts of the two mixing arms are connected through a connecting plate; the lower ends of the planetary wheel shafts are connected with the connecting plates; and a vibration mechanism is arranged in the lower barrel body. According to the planetary concrete mixer, the microcosmic uniformity of concrete can be effectively improved.

Owner:CHANGAN UNIV

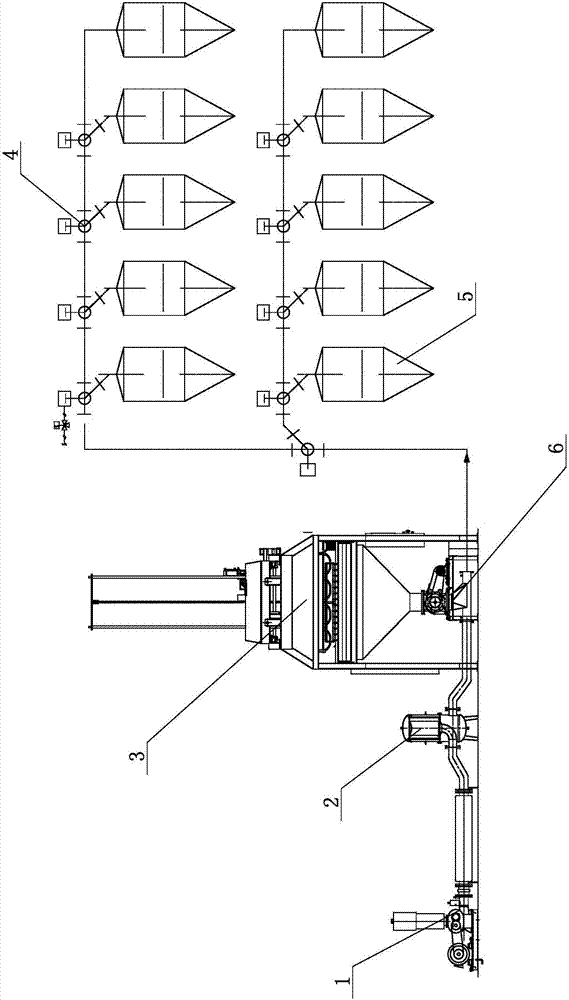

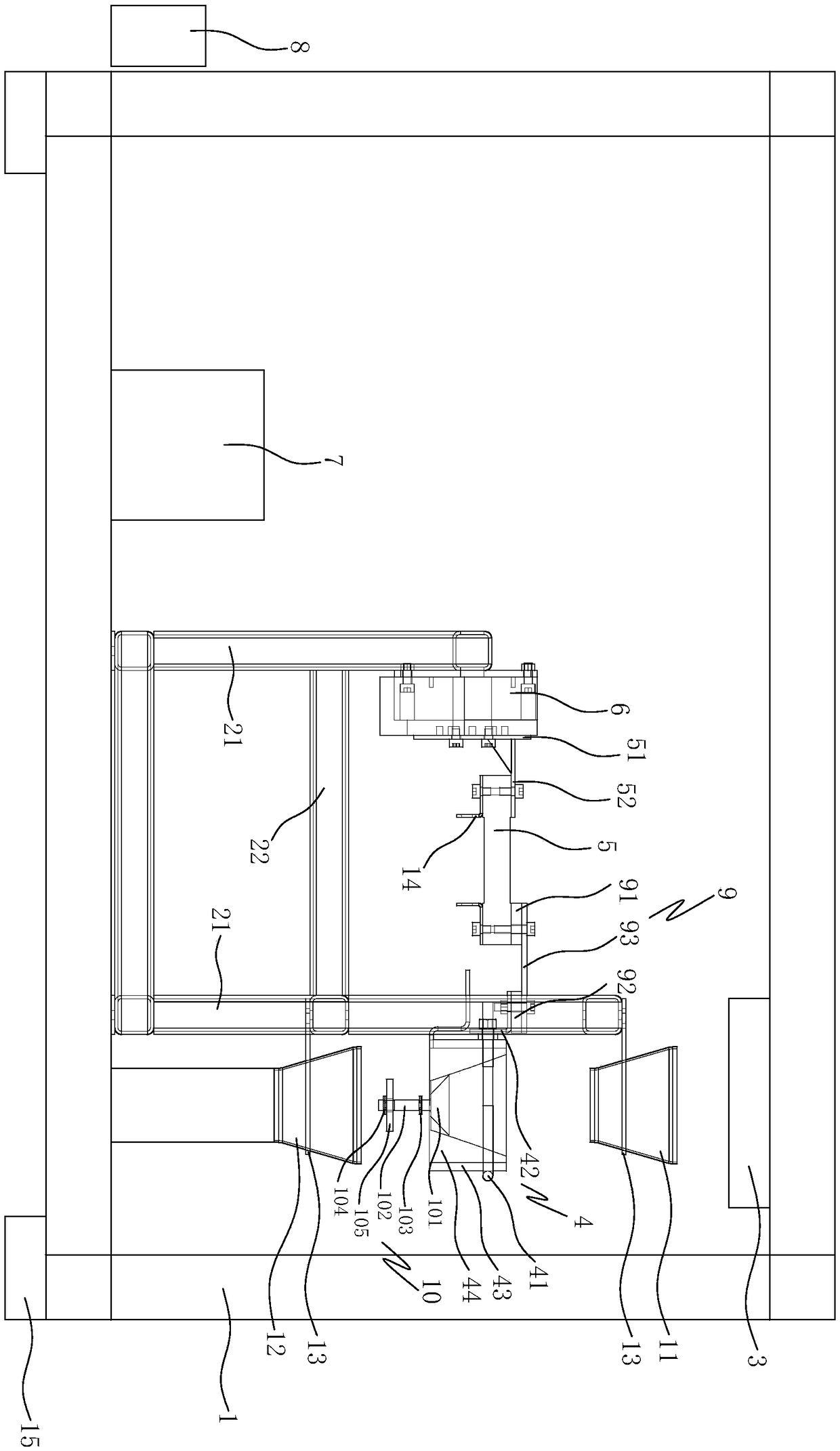

Full-automatic bag breaking feeding system

InactiveCN107089392AHigh degree of automationSave human effortStacking articlesDe-stacking articlesAutomationWhole systems

The invention relates to the technical field of bag breaking and feeding, in particular to a fully automatic bag breaking and feeding system, which includes a bag breaking unloading machine and an air supply device. The discharge port of the discharge machine is connected to the material conveying pipeline, the left end of the material conveying pipeline is connected with the air supply device, and the right end of the material conveying pipeline is connected with multiple groups of silos; the whole system has a high degree of automation, greatly reducing the manpower required and saving Reduce labor costs and improve production efficiency.

Owner:山东兴玉机械科技有限公司

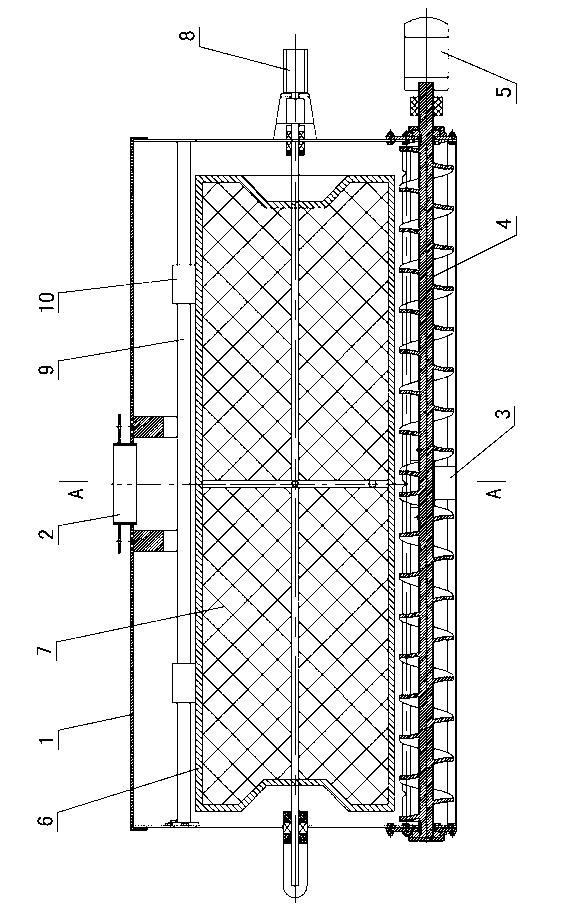

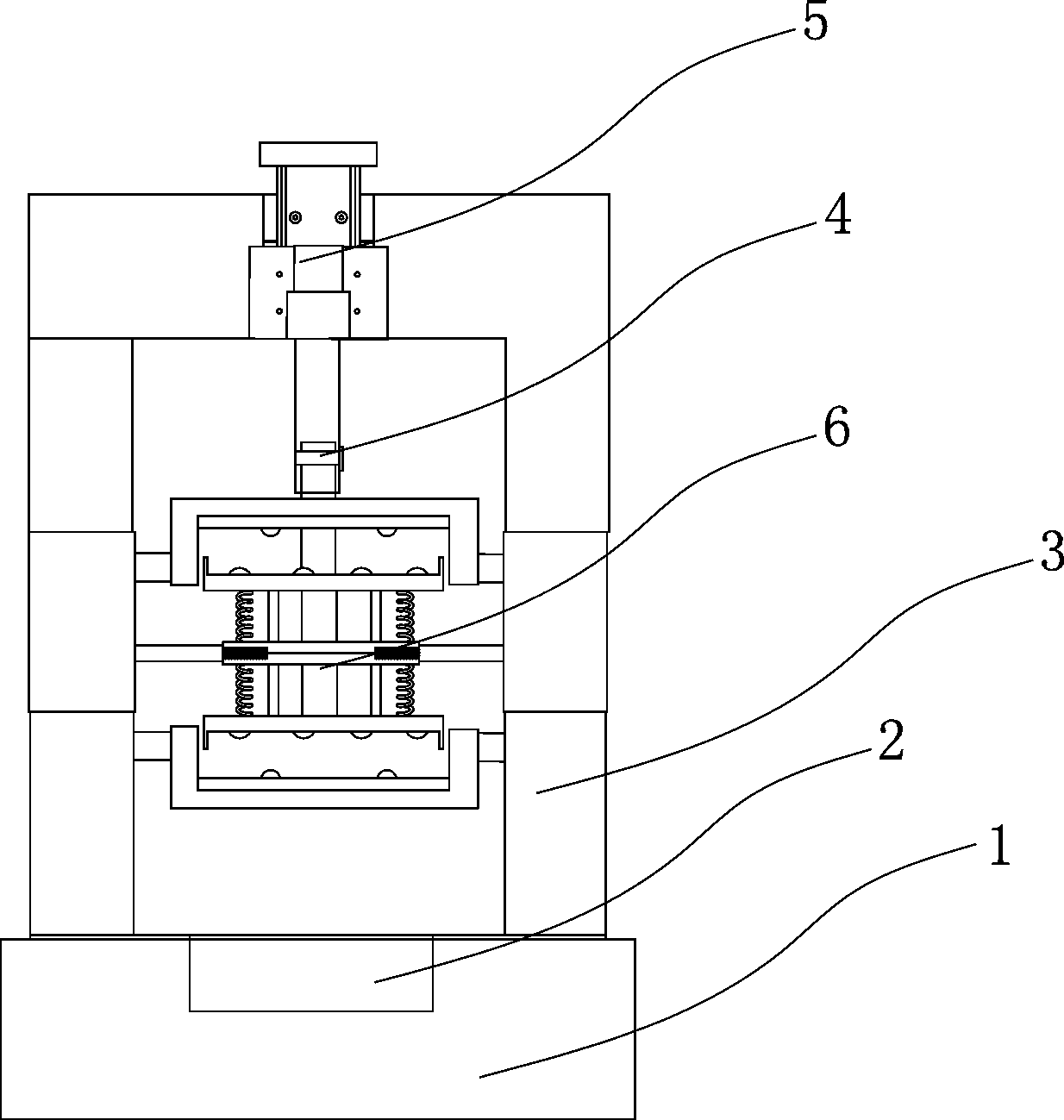

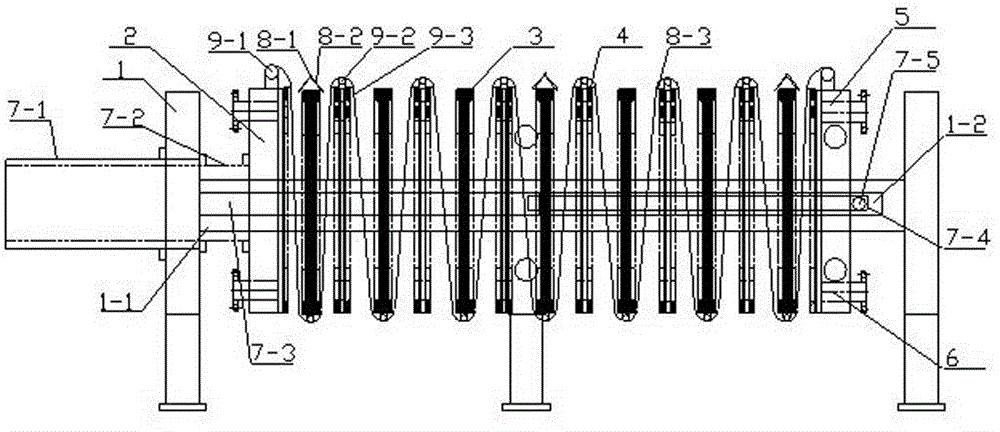

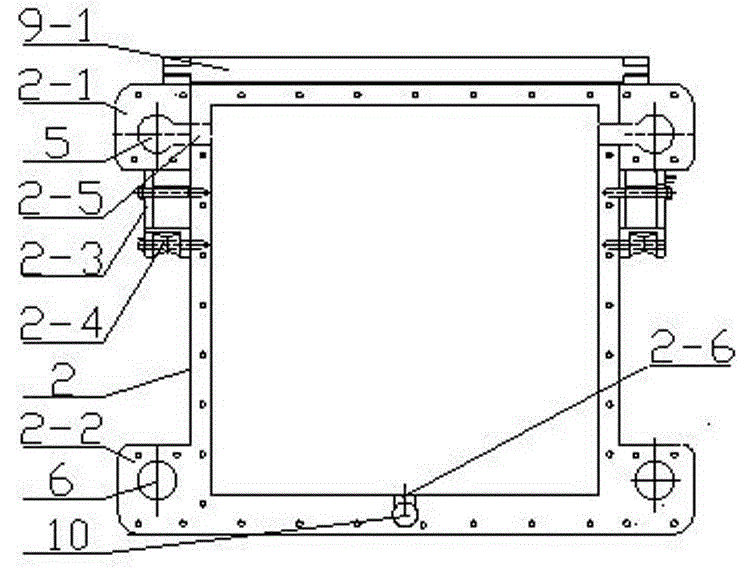

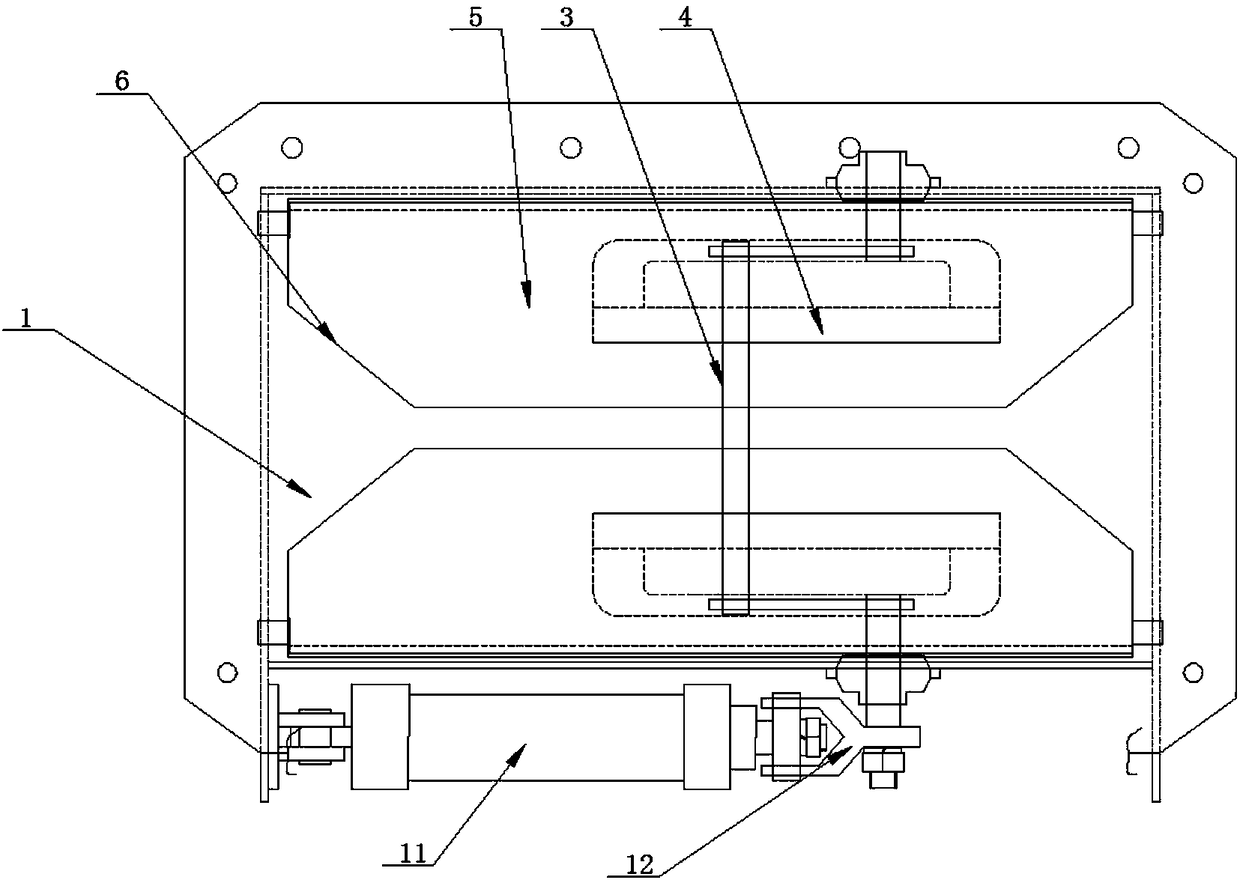

Solid and liquid separator for materials

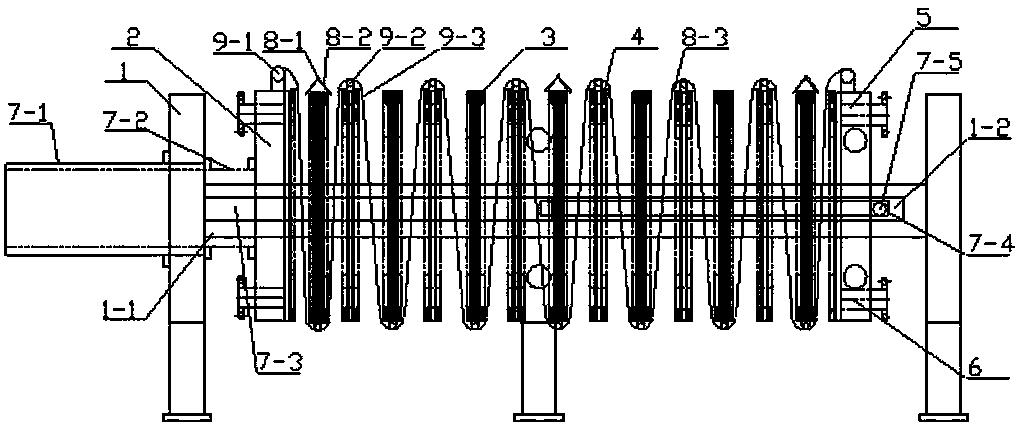

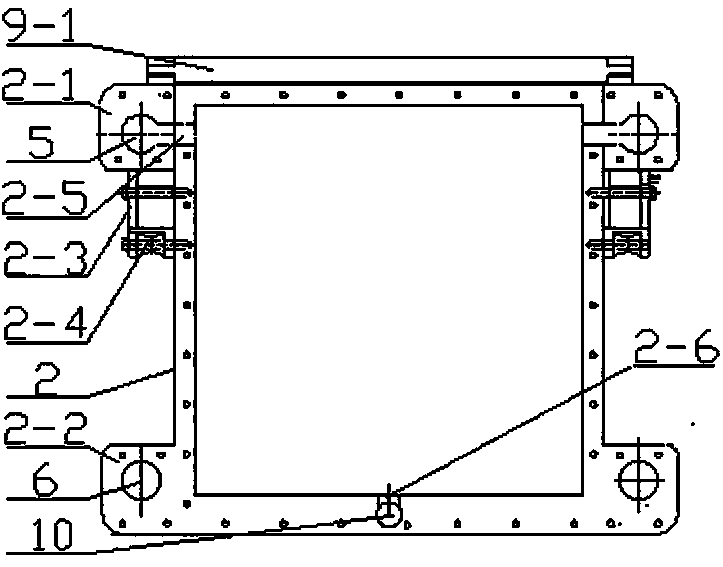

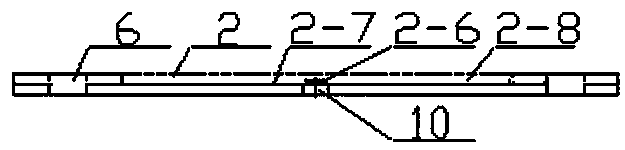

ActiveCN103657176AImprove stressThe moisture content of solids is reducedFiltration separationPush and pullLocking mechanism

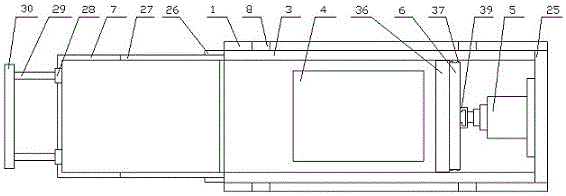

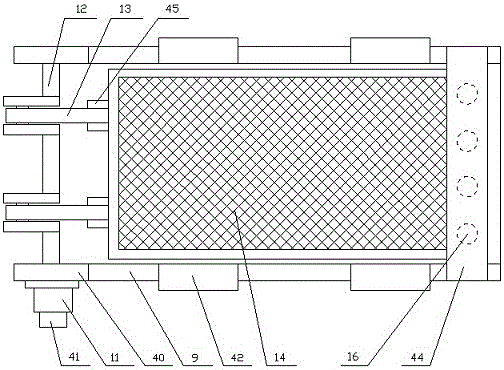

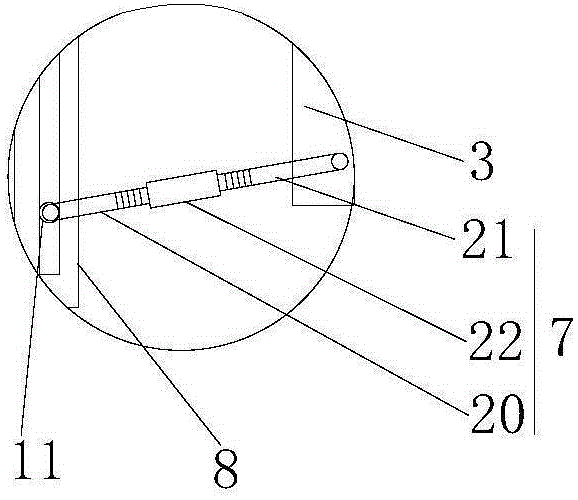

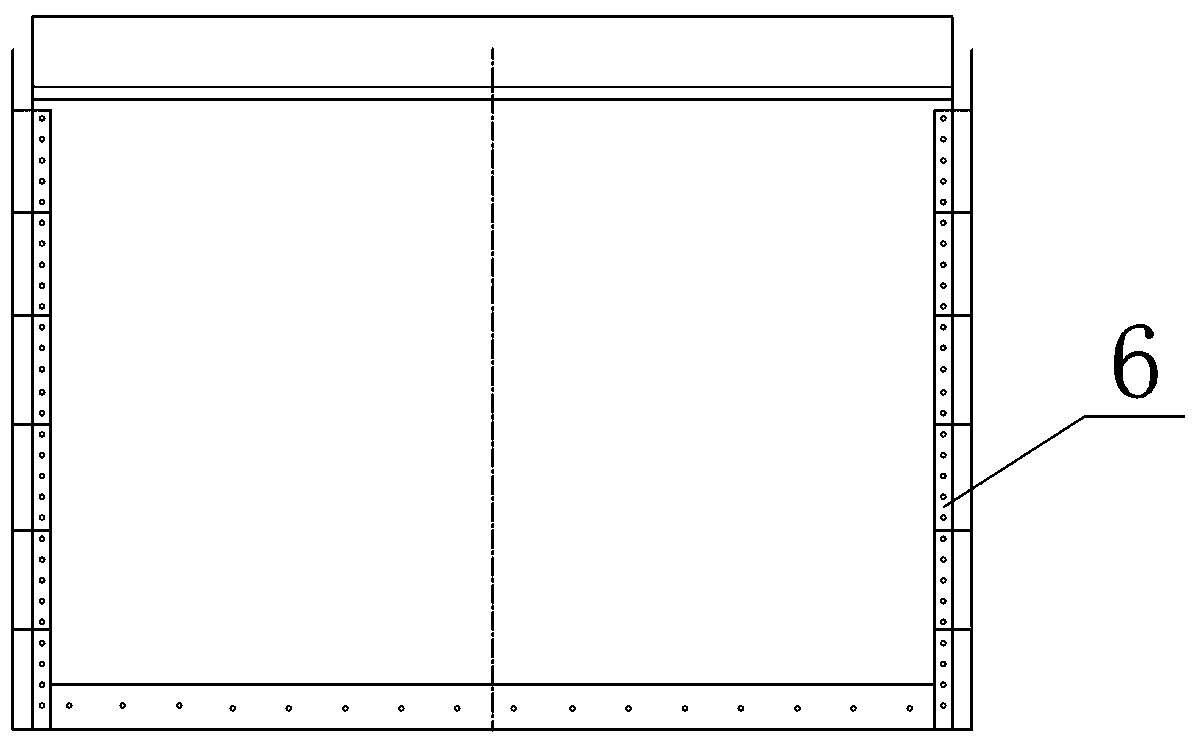

The invention discloses a solid and liquid separator for materials. The solid and liquid separator comprises a frame, press plates, filter plates, a push-and-pull locking mechanism, a filter cloth mechanism, a filter cloth regeneration mechanism and a cleaning mechanism which are arranged on the frame, wherein the press plates and the filter plates are arranged on the frame in a sliding way alternately, and are matched to extrude a material, so that solid and liquid of the material can be separated; the push-and-pull locking mechanism is used for locking, pushing away all the press plates and filter plates, so that solid-liquid separation operation can be performed, or the material can be discharged; the filter cloth mechanism is used for separating solid and liquid of the material when the material is extruded; the filter cloth regeneration mechanism is used for washing to regenerate the filter cloth after the material is discharged; the cleaning mechanism is used for cleaning the material attached to the separator after solid and liquid of the material are separated. The solid and liquid separator has the characteristics of reasonable design, high structure strength, convenience in operation, complete solid and liquid separation, high separation efficiency, convenience in cleaning, long service life, log maintenance frequency, high reliability, strong practicality and the like, and is beneficial for greatly increasing production benefit of enterprises.

Owner:四川宝凯鑫诚环保科技有限公司

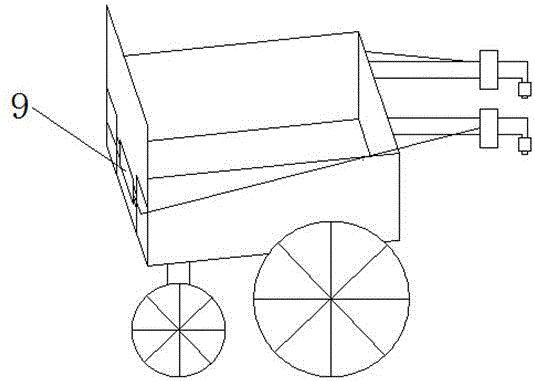

Trolley for conveying concrete

InactiveCN105857366AEasy unloadingSave manpower and timeFluid steeringHand carts with multiple axesEngineering

The invention discloses a trolley for conveying concrete, comprising a trolley body and a handle disposed at the rear end of the trolley body. The trolley body is in the shape of forwardly oblique rectangle, left and right sides of the trolley body are each provided with a wheel, a support rod is disposed on the lower portion of the trolley body, one end of the support rod is fixedly connected with the trolley body, the other end of the support rod is provided with a small wheel, the front end of the trolley body is provided with a moving retainer, the moving retainer is hinged to the trolley body, left and right ends of the moving retainer are bent up, forming discharge side retainers, left and right front ends of the trolley body are provided with fixed retainers, and the fixed retainers are hinged to the trolley body. The trolley enables simple and clean discharging during usage, saves discharging time and labor, and is also very easy to clean before replacing material to be conveyed.

Owner:刘瑞

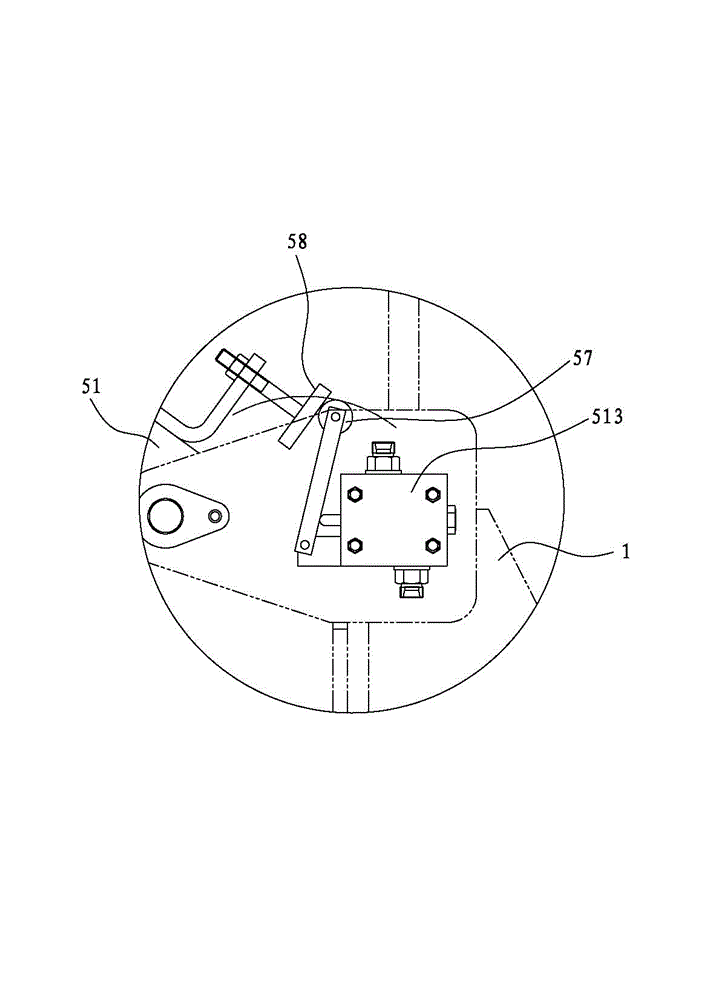

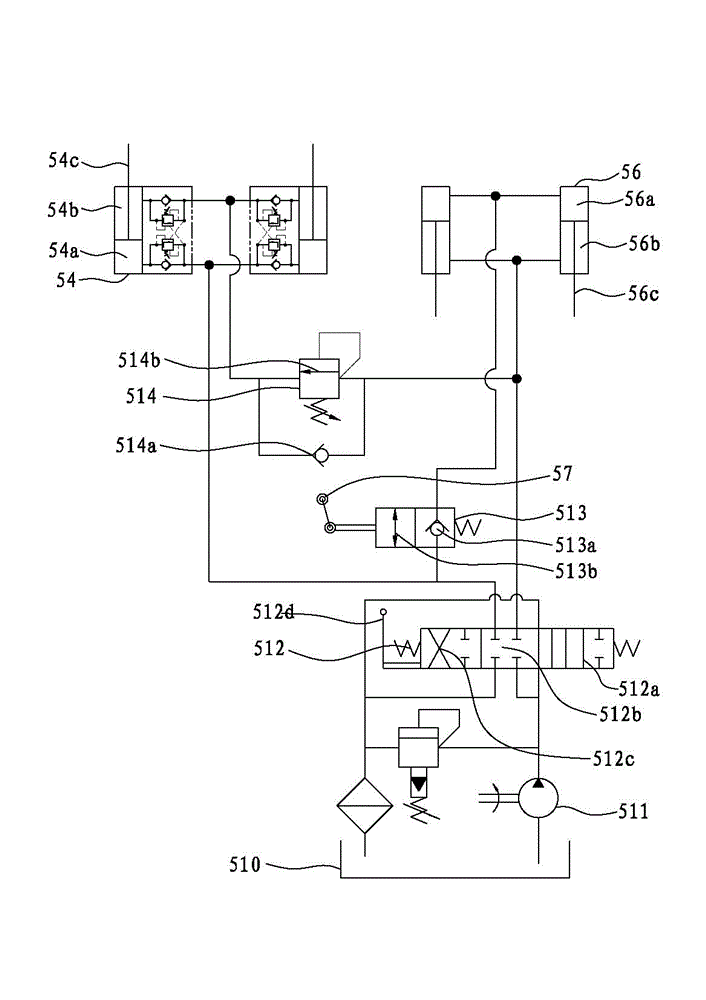

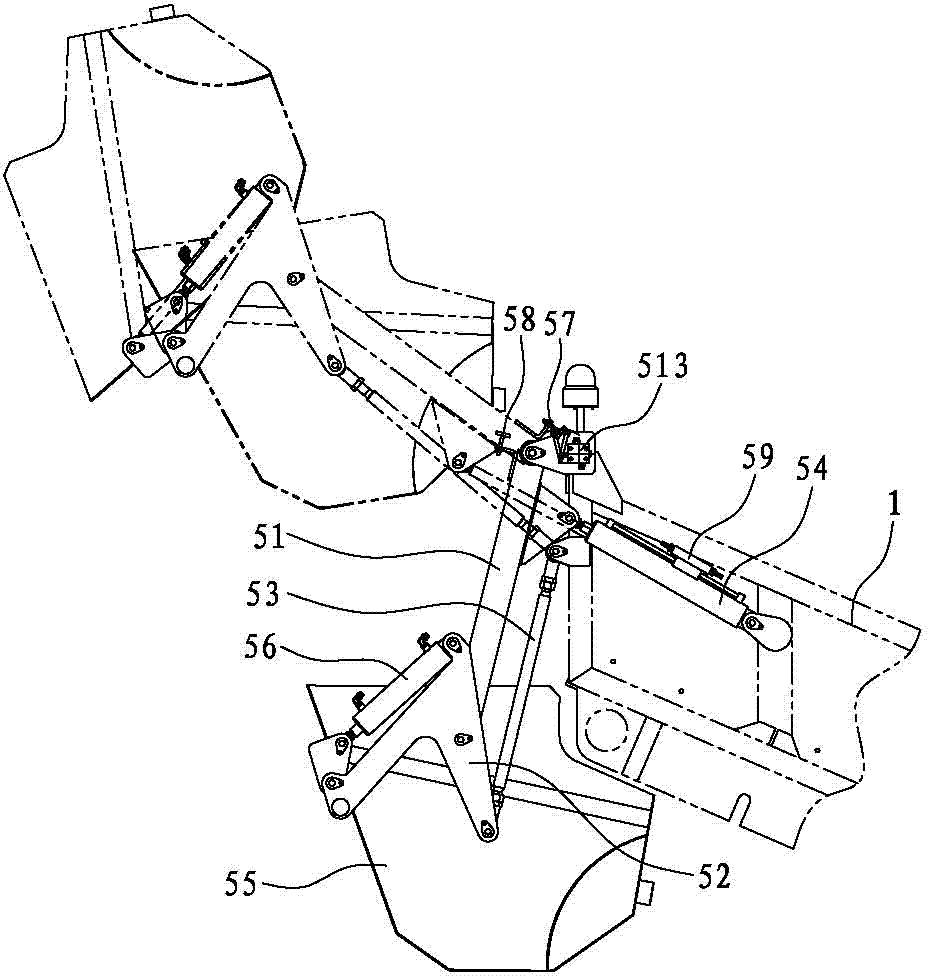

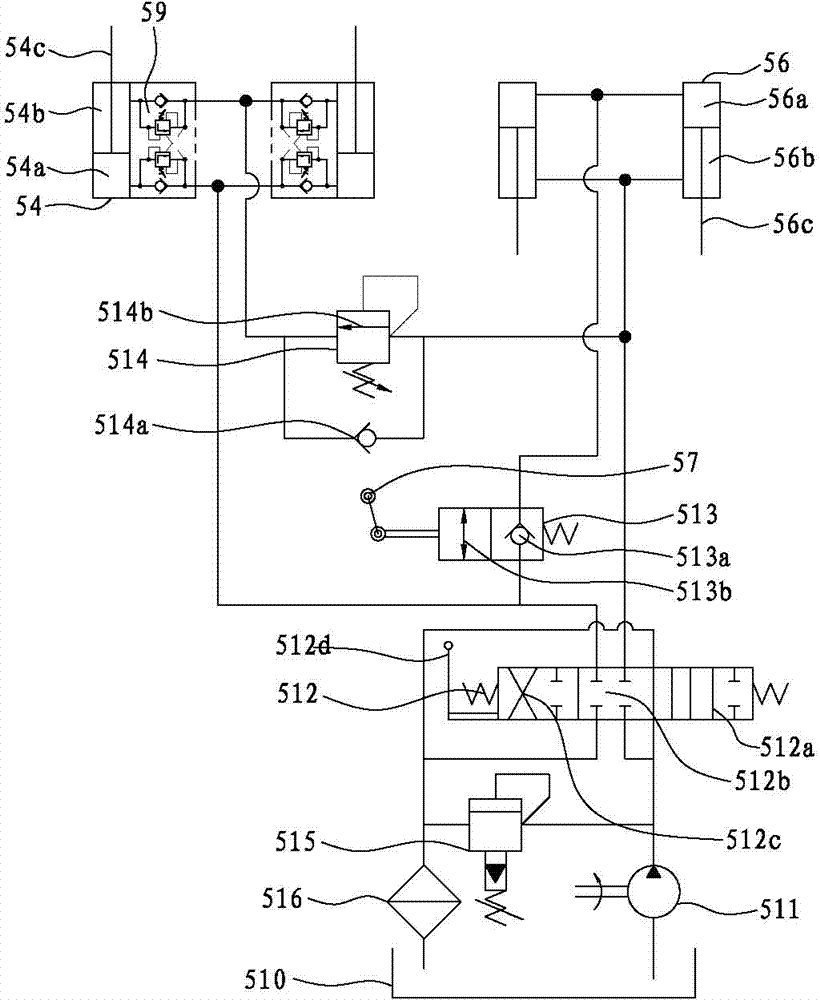

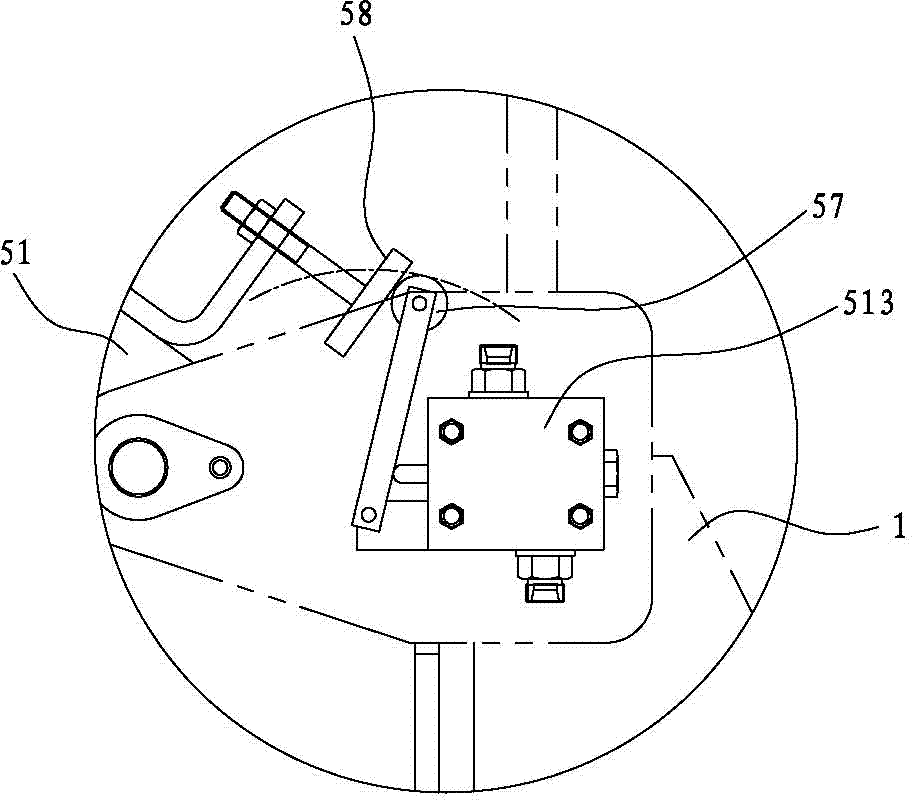

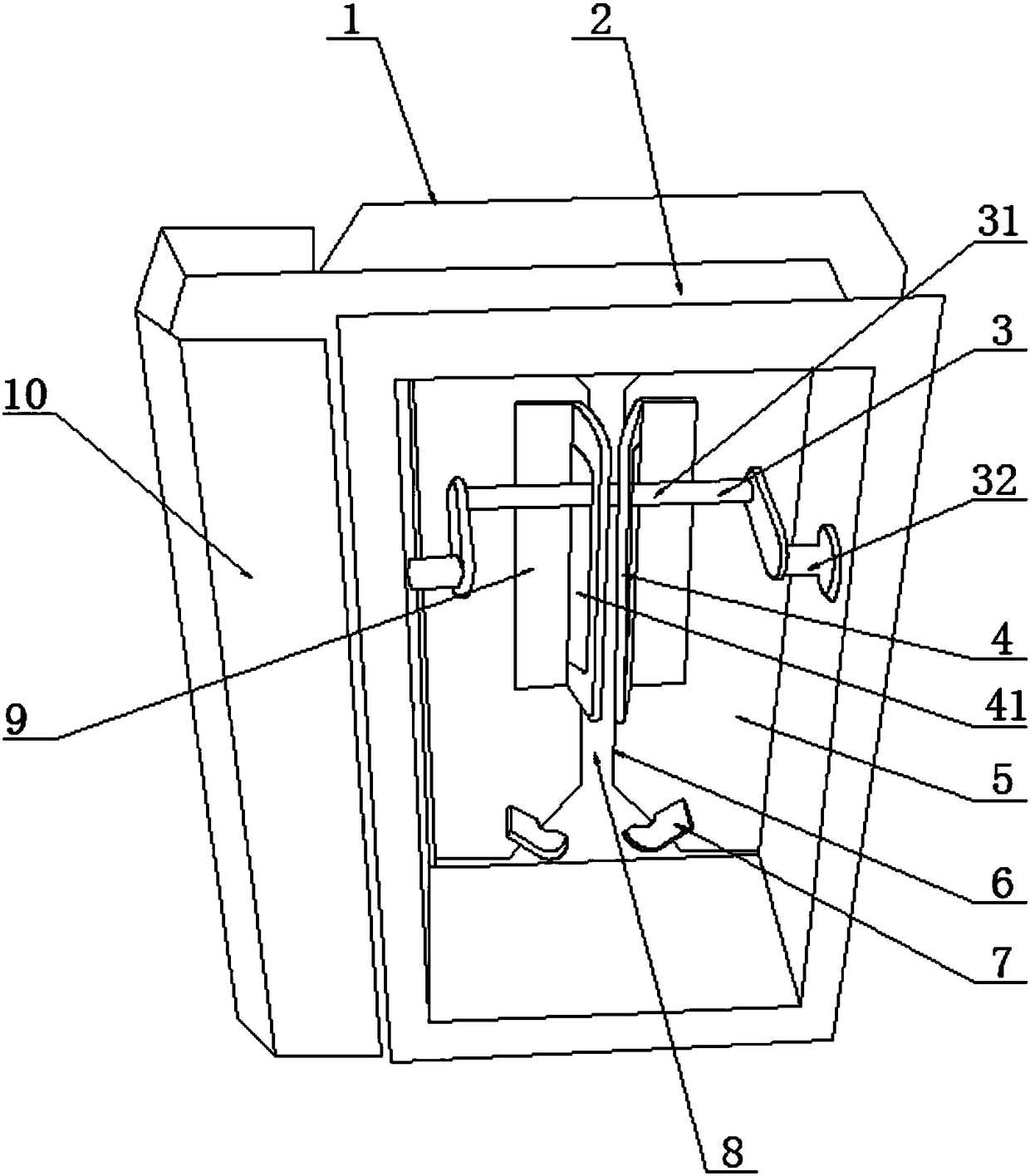

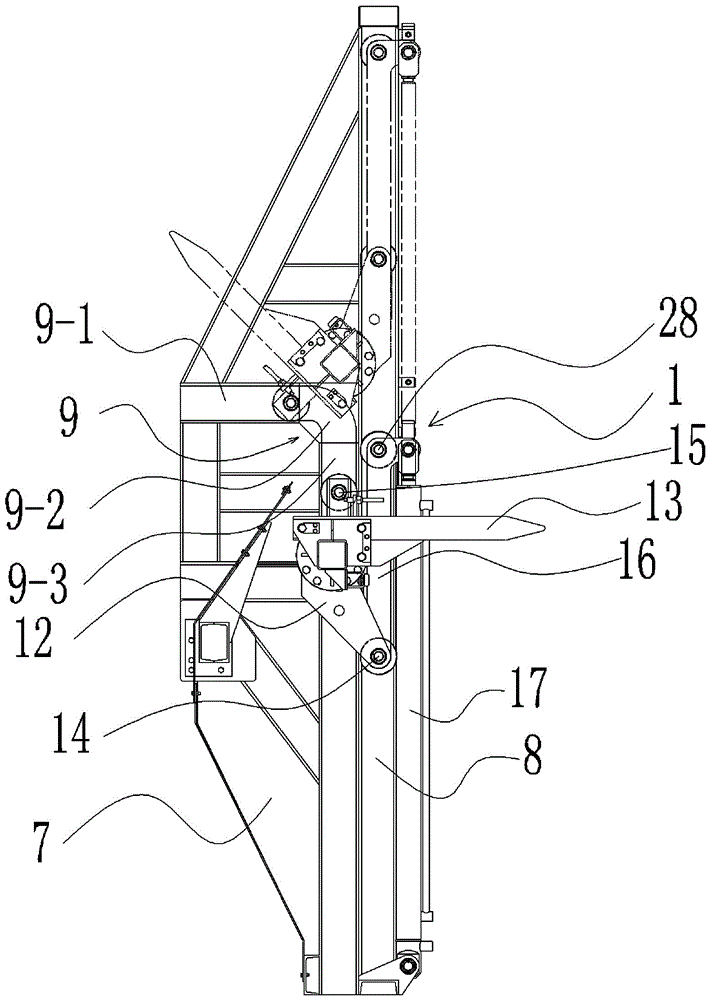

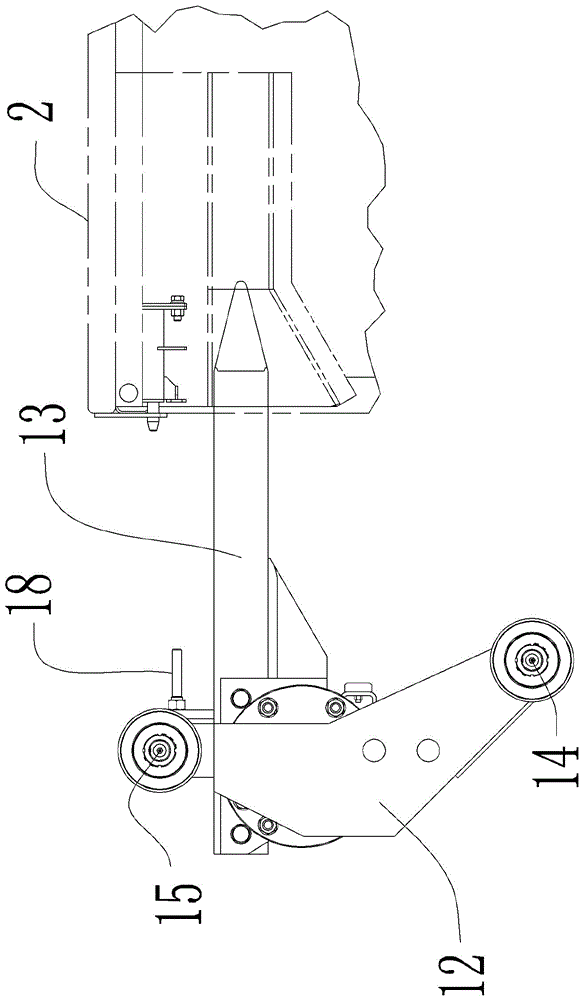

Lifting and turning-over mechanism of cleaning vehicle garbage bin and control method thereof

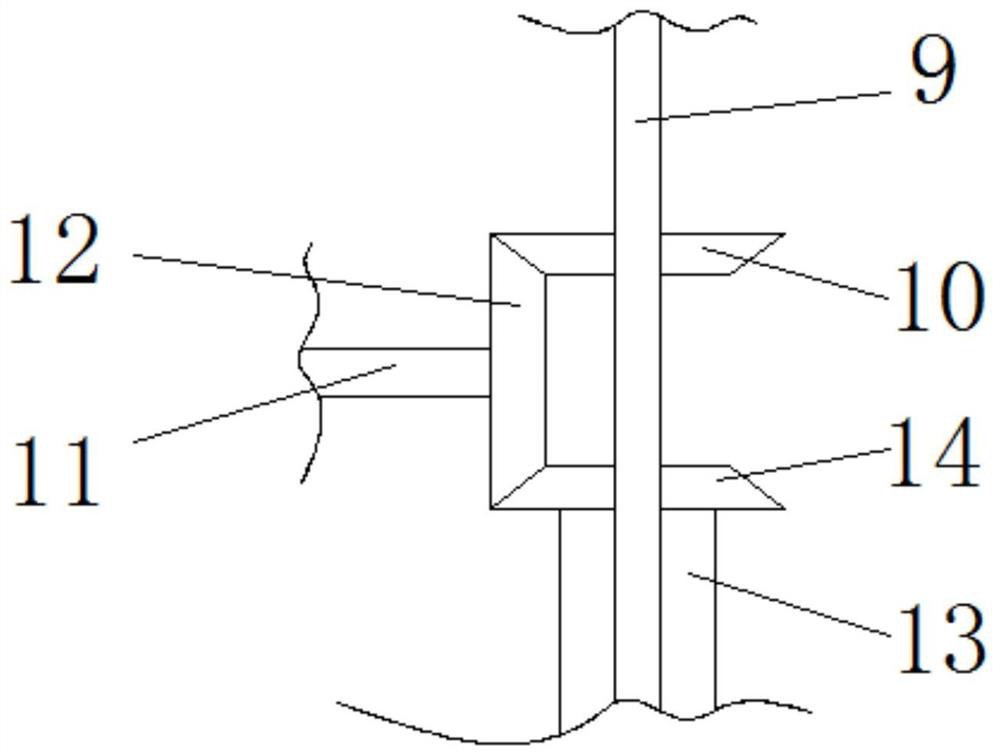

InactiveCN102758414APrevent leakageLarge flip angleRoad cleaningCleaning bleachesControl systemJunk box

The invention discloses a lifting and turning-over mechanism of a cleaning vehicle garbage bin, which is fixed on the frame of the cleaning vehicle, and includes a lifting arm, a turning-over seat, a connecting rod, a lifting oil cylinder, a garbage bin and a turning-over oil cylinder, wherein the lifting arm, the turning-over seat, the connecting rod and the frame are hinged to form a plane four-connecting rod mechanism; one end of the cylinder barrel of the lifting oil cylinder is hinged onto the frame, and one end of the piston rod is hinged onto the lifting arm, so as to drive the plane four-connecting rod mechanism to be lifted or lowered; and the turning-over seat, the garbage bin and the turning-over oil cylinder are hinged to form a swinging block mechanism, and the turning-over oil cylinder drives the swinging block to enable the garbage bin to turn over. As lifting and turning-over are performed through two mechanisms respectively, by adopting the control system to realize lifting and turning-over sequentially, not only the garbage scattering during the dumping is avoided, but also the independently-controlled turning-over mechanism enables the turning-over angle to be sufficiently large, so as to dump more completely and cleanly. The invention also discloses a control method of the lifting and turning-over mechanism.

Owner:厦门威迪思汽车设计服务有限公司

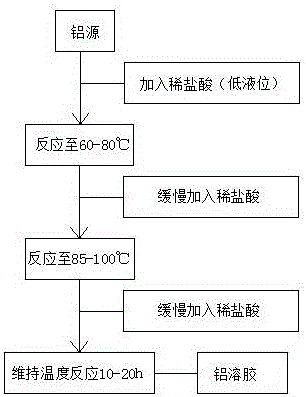

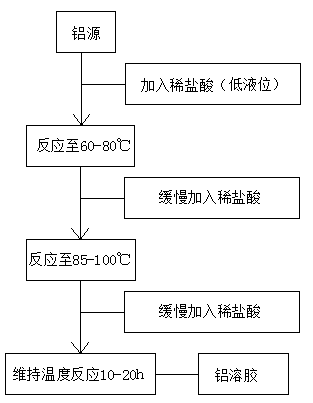

Aluminum soil production method

ActiveCN106268549AReduce investmentFully control the reaction rateAluminium chloridesSol preparationChemical industryHydrogen

The invention relates to the technical field of chemical industry and in particular relates to an aluminum soil production method. A single-kettle charge production manner is adopted; a reaction kettle internally comprises a stock bin for containing an aluminum source; in a production process, the aluminum source is added into the stock bin and the first part of diluted hydrochloric acid is added into a kettle body, wherein the adding amount is one-tenth to one-third of the total mass; the diluted hydrochloric acid reacts with the aluminum source at the lower part of the stock bin; after reaction temperature is stabilized to 60 DEG C to 80 DEG C, the temperature is kept for 15min to 30min; then the second part of diluted hydrochloric acid is slowly added; after the reaction temperature reaches 85 DEG C to 100 DEG C, the third part of diluted hydrochloric acid is slowly added; the reaction temperature is stabilized to 85 DEG C to 100 DEG C through the speed of adding the third part of diluted hydrochloric acid; after reaction is carried out for 12h to 20h, aluminum soil with the Al / Cl mass ratio of 1.0 to 2.0 and the pH (Potential of Hydrogen) of 2.4 to 3.2 is finally obtained, and total acid adding time is controlled to be 3h to 10h. According to the aluminum soil production method, an intermittent production process is adopted and a normal-pressure spontaneous reaction is carried out; a reaction speed is sufficiently controlled in a reaction process and spontaneous heat generated by the reaction is reasonably utilized; in a whole production process, stirring and steam heating are not needed, so that the energy consumption can be reduced by 80 percent or more when being compared with that of a traditional production process.

Owner:REZEL CATALYSTS CORP

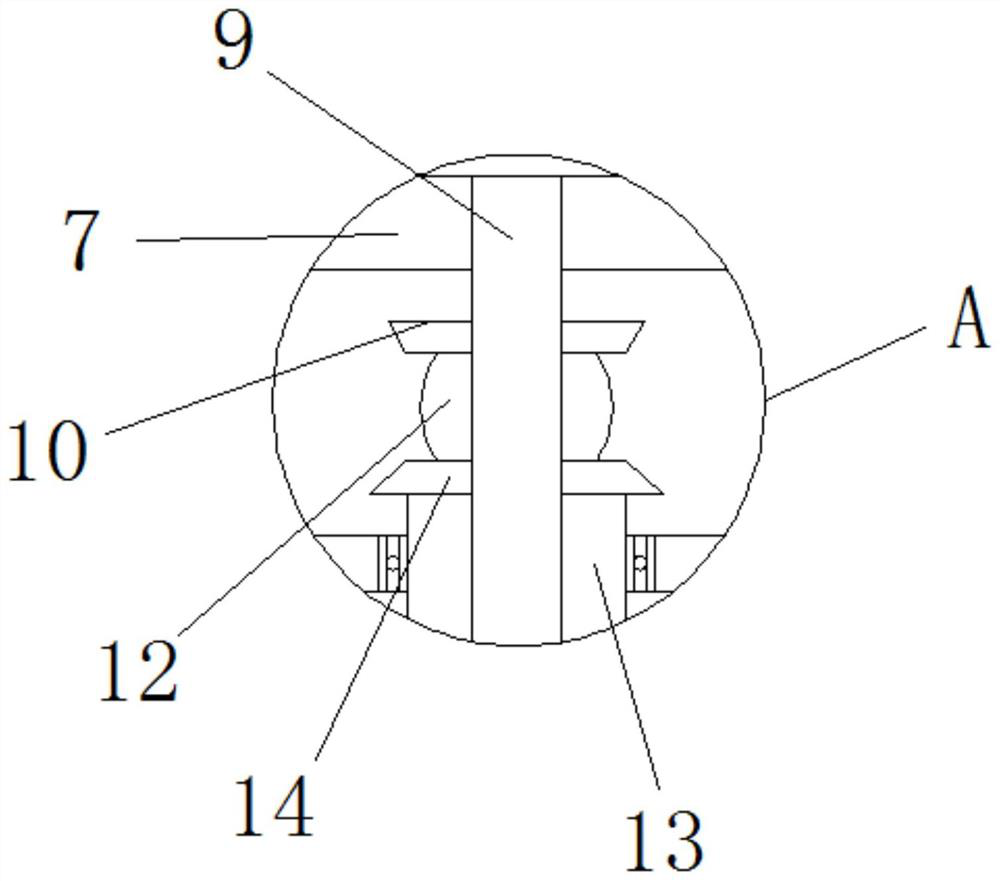

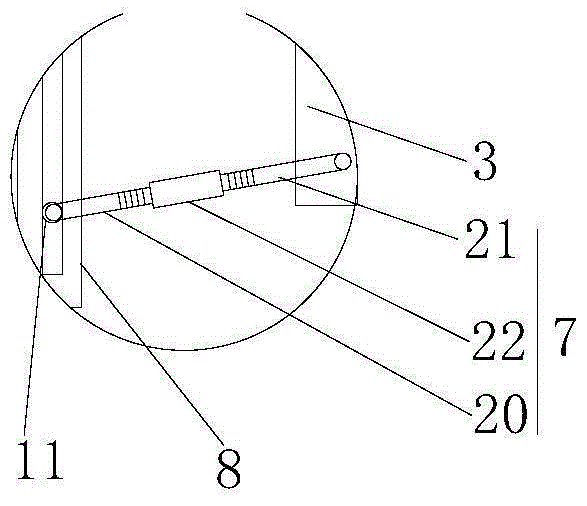

Tea rolling machine

InactiveCN107691689AImprove efficiencyUnload cleanPre-extraction tea treatmentHydraulic cylinderEngineering

A tea rolling machine comprises a base, wherein a support is arranged on the base, a hydraulic cylinder is arranged at one end of the support, a mechanical gripper is arranged at the lower end of thehydraulic cylinder to grab a rolling mechanism, the rolling mechanism comprises an upper casing and a lower casing, fixing rods are connected with two sides of the upper casing and the lower casing, the other end of each fixing rod is fixed with the support, slide rails are arranged on two sides of the support, the fixing rods slide on the slide rails, a middle seat is arranged on inner sides of the upper casing and the lower casing, and an upper disc and a lower disc are arranged on upper and lower sides of the middle seat respectively. The tea rolling machine has the benefits as follows: theupper disc and the lower disc can roll different sizes or types of tea, the efficiency is high, manual feeding and discharging are not required, and complete uploading can be realized.

Owner:宁波市晶杰国际物流有限公司

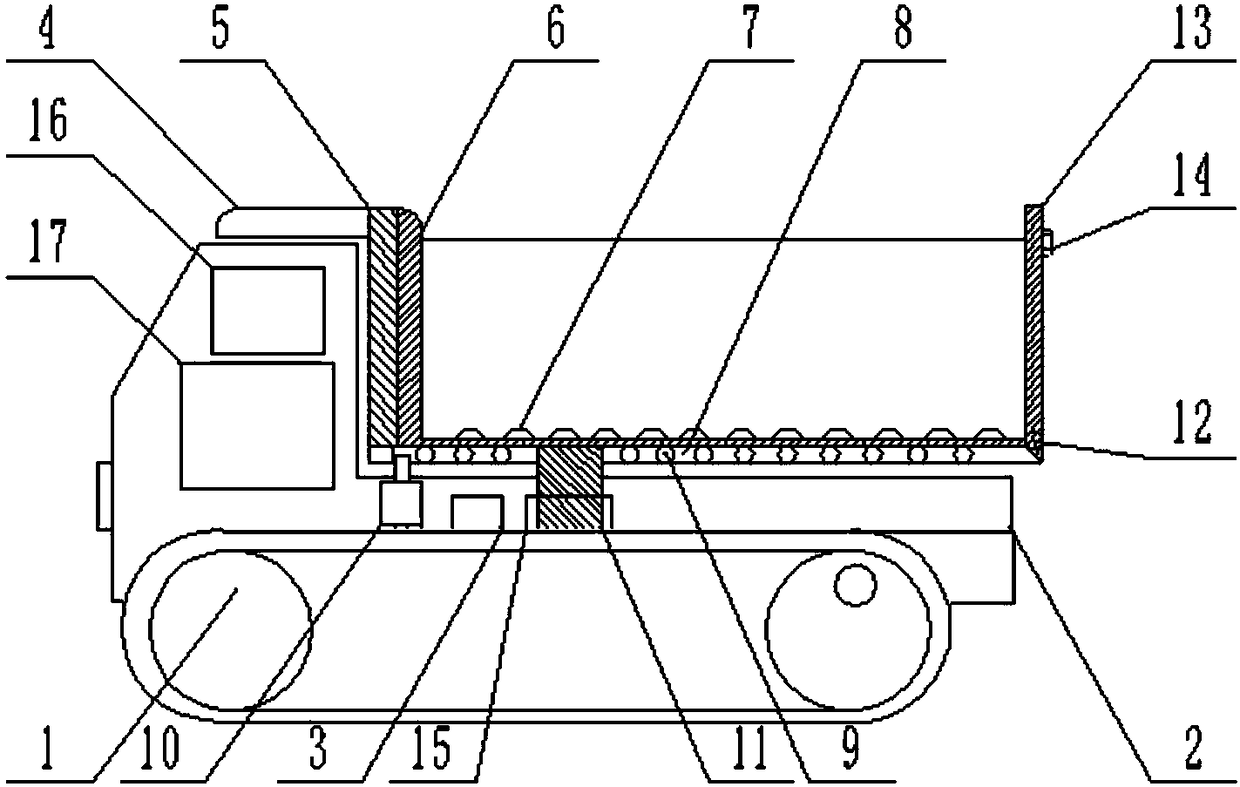

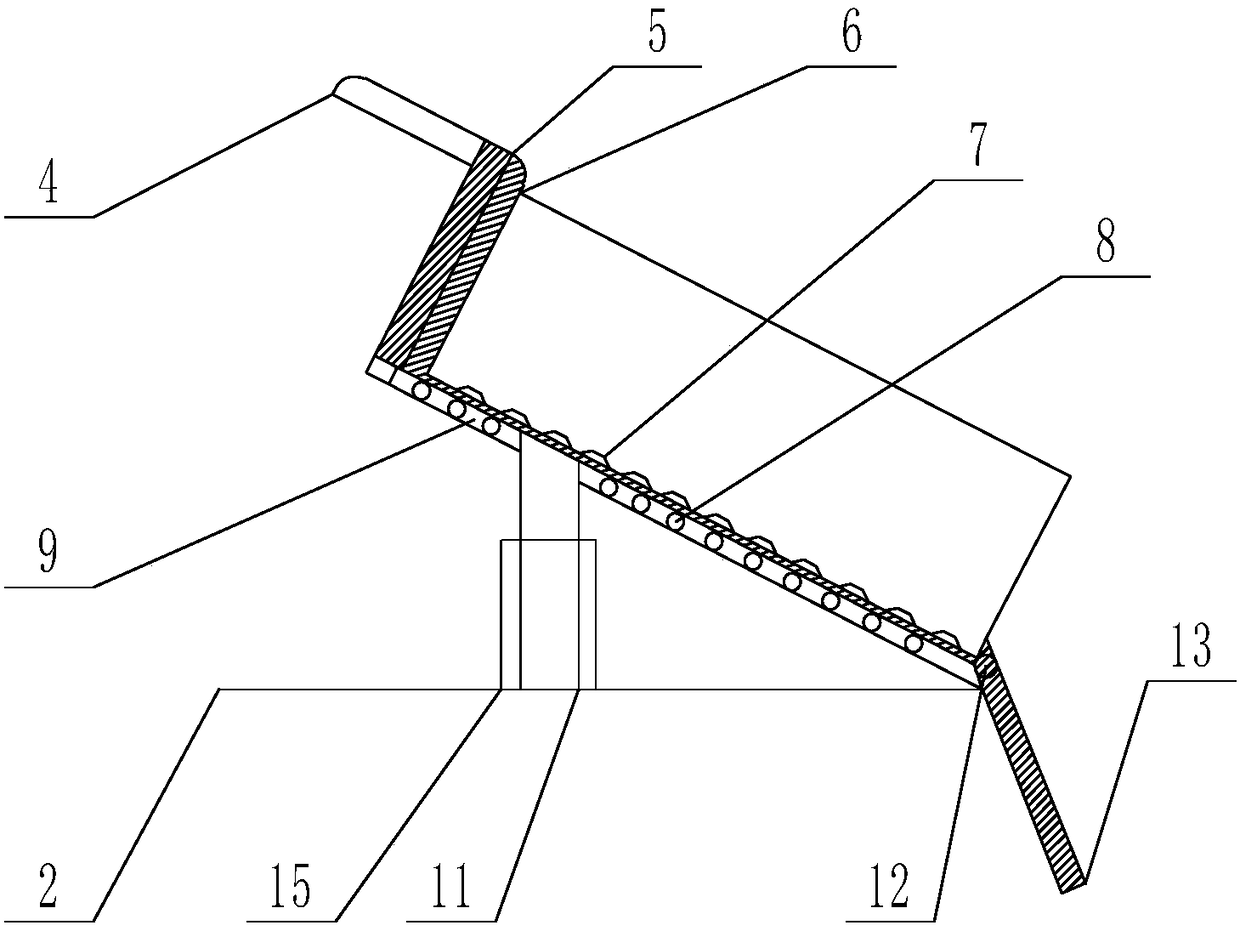

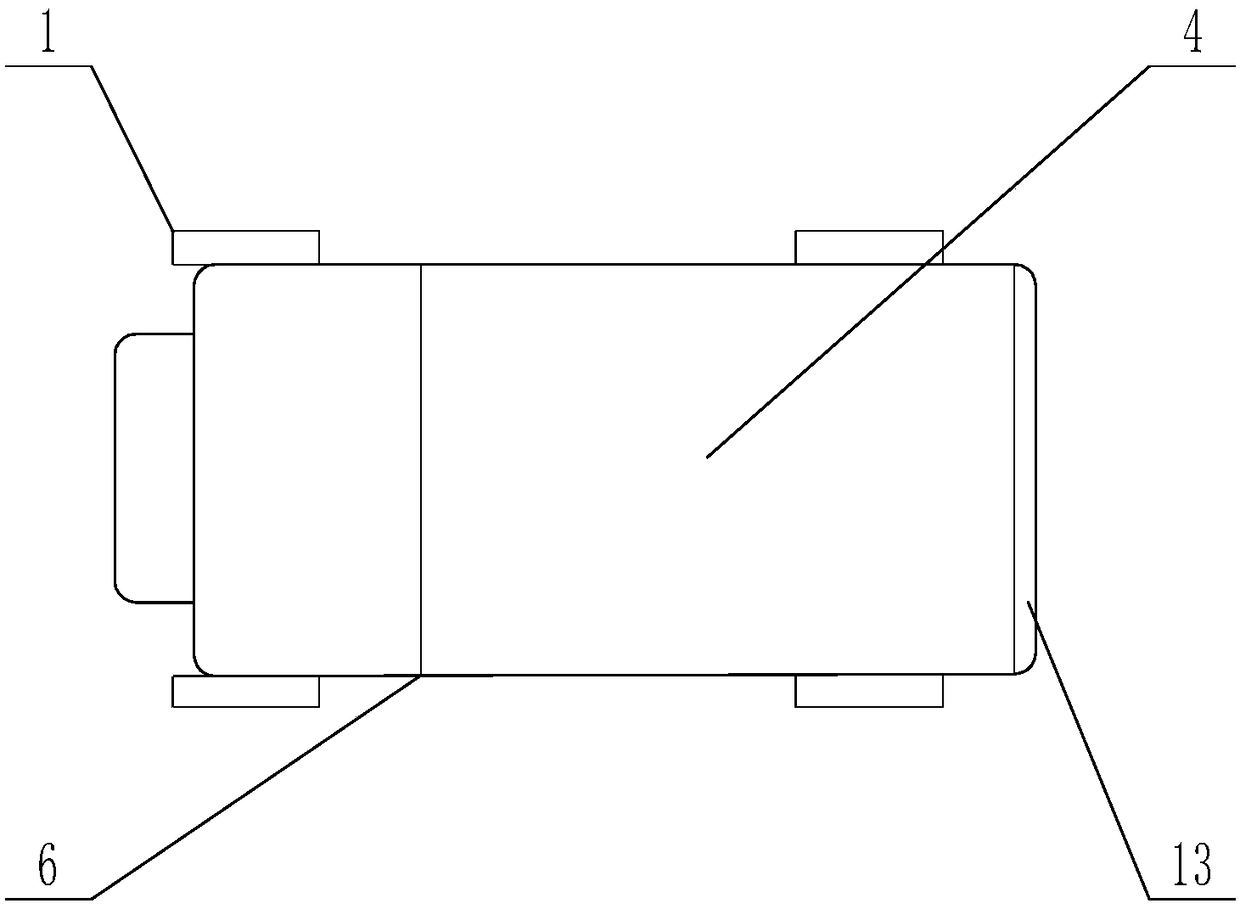

Novel flexible dumper

InactiveCN108099737AUnload cleanGuaranteed loading and unloading operationsVehicle with rollersVehicle with tipping movementEngineeringMechanical engineering

The invention discloses a novel flexible dumper, which comprises a crawler wheel, a carriage, and a revolving wheel; the upper part of the crawler wheel is provided with a car body and an engine, oneside of the car body is provided with a damping device; one side of the damping device is provided with an inside push door, one side of the inside push door is provided with a friction belt; the lower part of the friction belt is provided with a track; the inner part of the track is provided with a roll bead; the lower part of the roll bead is provided with a buckle block and a hydraulic cylinder, and outside of the hydraulic cylinder is provided with a flexible cylinder; a back carriage door and a locking screw are arranged on the revolving shaft, the front side of the back carriage door isprovided with a display screen and a control cabinet. The novel flexible dumper has the beneficial effects that through designing the novel flexible dumper, the dumper can dump clearly; meanwhile, dueto the flexibility of the track, the normal loading and unloading works of the dumper are guaranteed, the loading and unloading transportation efficiency of the dumper is improved.

Owner:滨州市金毅设备有限公司

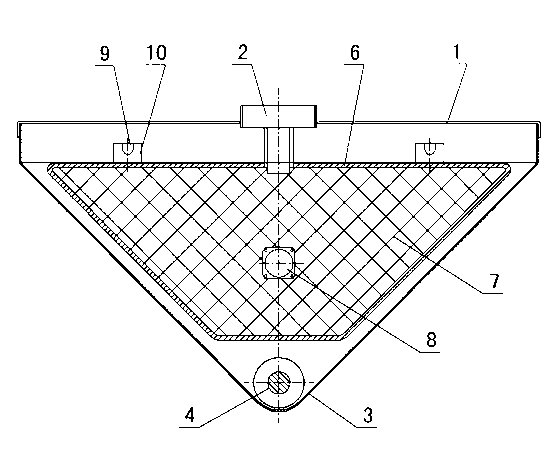

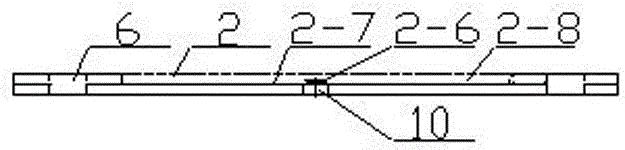

Rapid material unloading and storing barrel of plastic powder agitator

The invention provides a rapid material unloading and storing barrel of a plastic powder agitator. The rapid material unloading and storing barrel comprises a barrel body of a material storing barrel of the agitator; the section of the barrel body is in an inverted triangular shape; the barrel body is provided with a feeding opening and an unloading opening; the barrel body is internally provided with an unloading auger; the unloading auger is driven by an unloading motor; and the rapid material unloading and storing barrel is characterized in that the barrel body is internally provided with a net rack and the shape of the net rack corresponds to that of the barrel body; the net rack is provided with an inclined plane net; the net rack is driven by a pushing air cylinder to do left-right reciprocating motion; and a guide mechanism drives the net rack to move. In an unloading process, the pushing air cylinder drives the net rack to do the left-right reciprocating motion in the barrel body to loosen plastic powder and scrape plastic powder grains stuck on the barrel wall, so that the plastic powder can be rapidly unloaded from the unloading opening, and all the plastic powder is unloaded and is not remained.

Owner:ZHEJIANG CHENTAI DECORATION MATERIAL

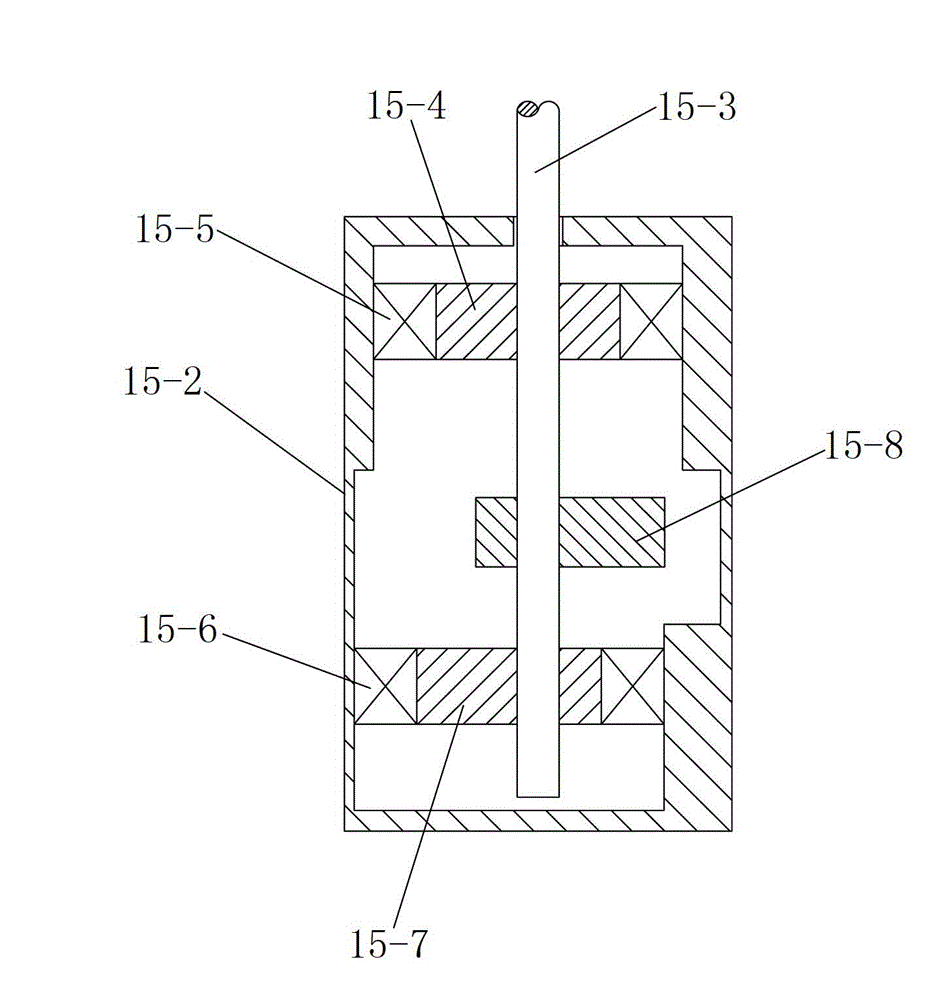

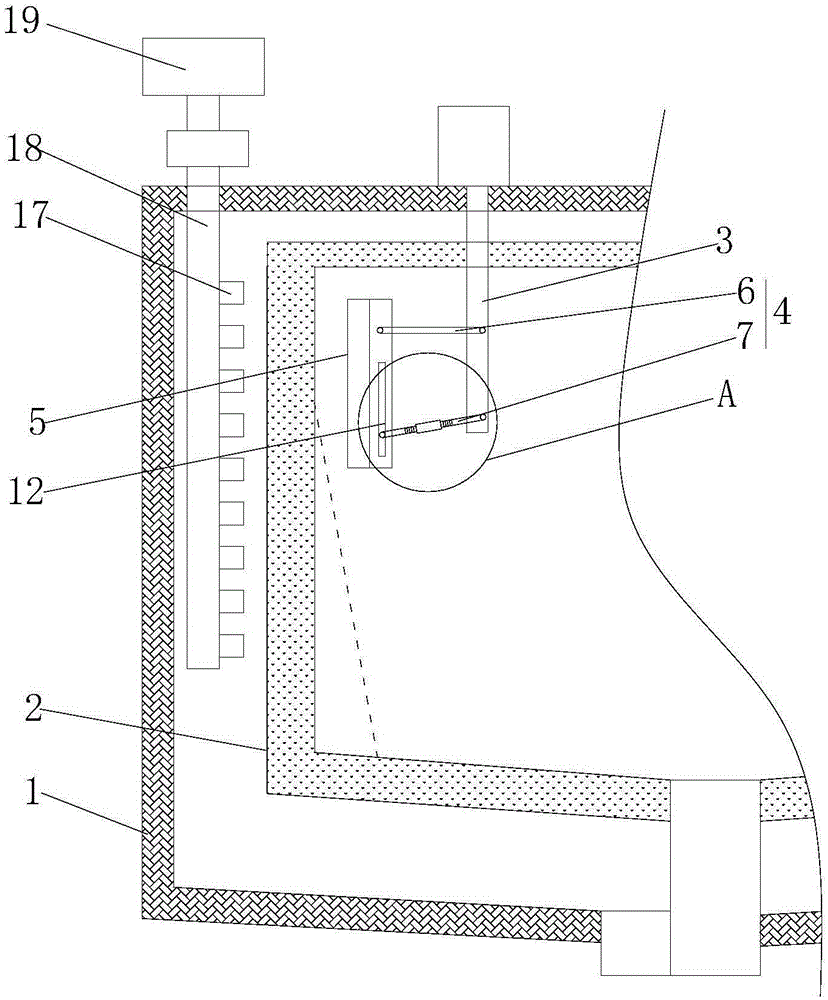

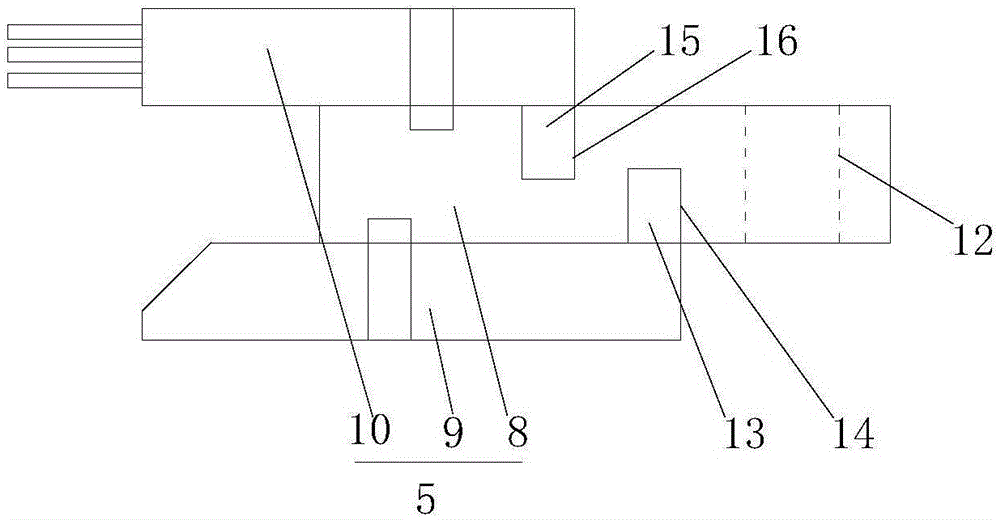

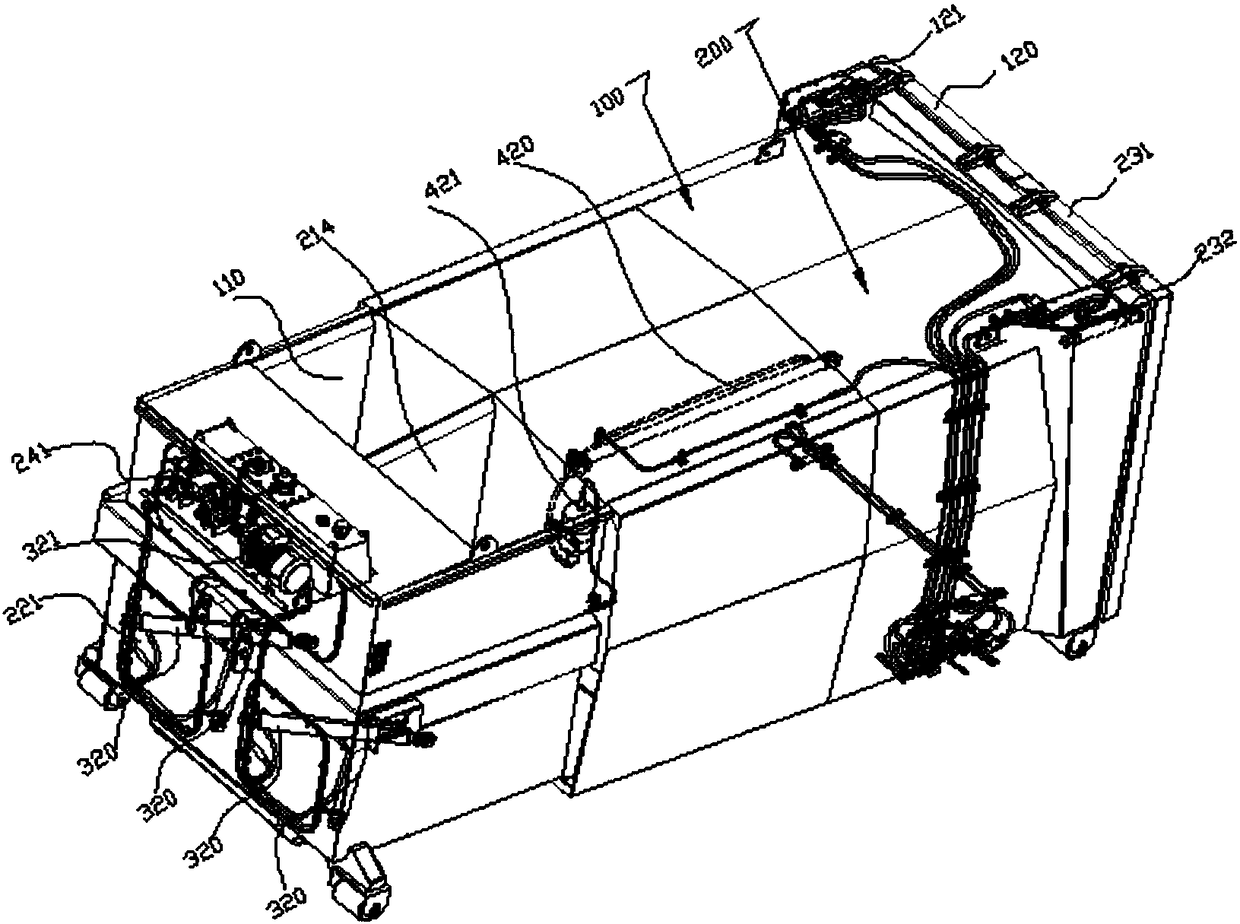

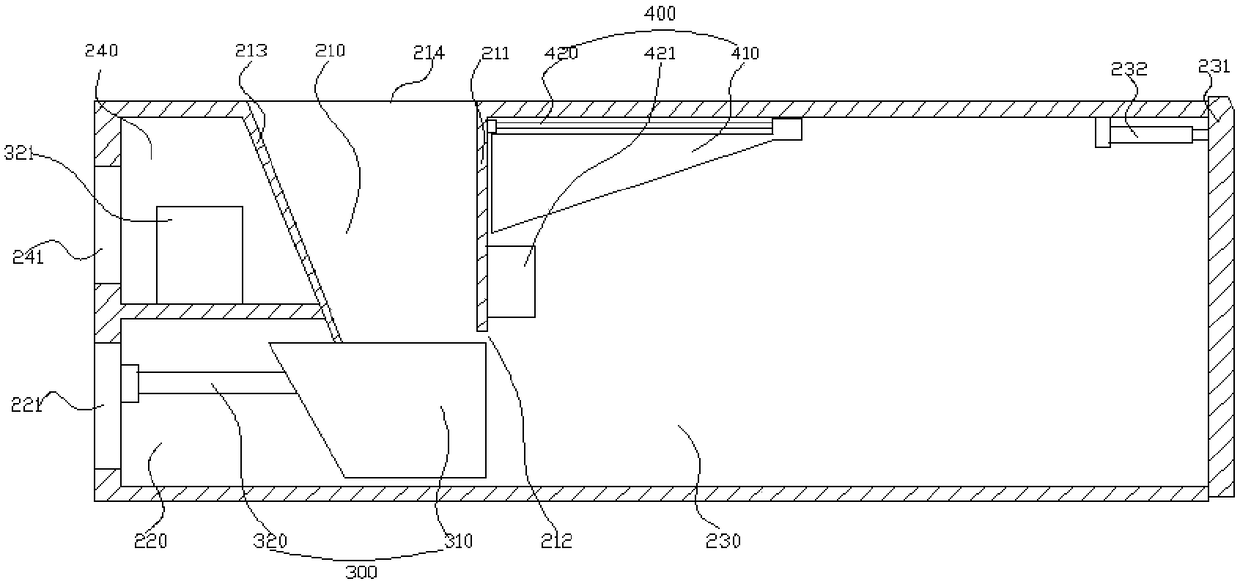

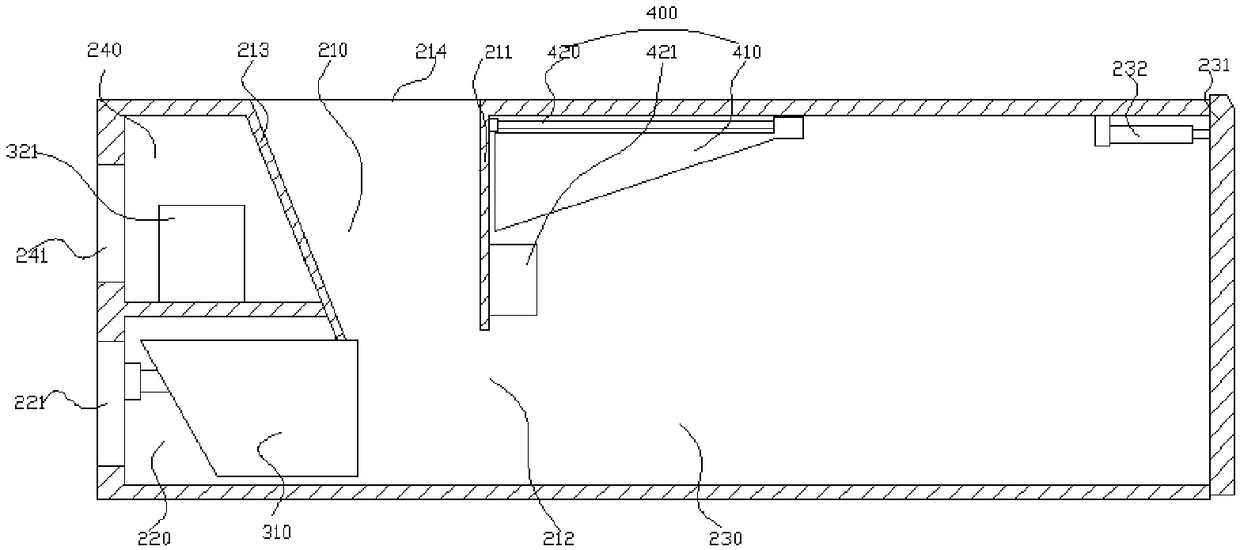

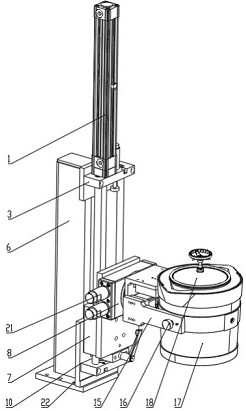

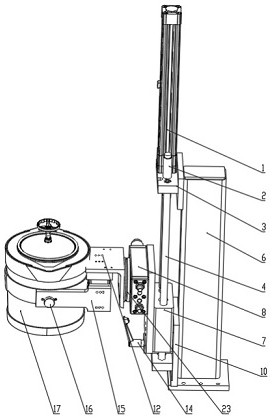

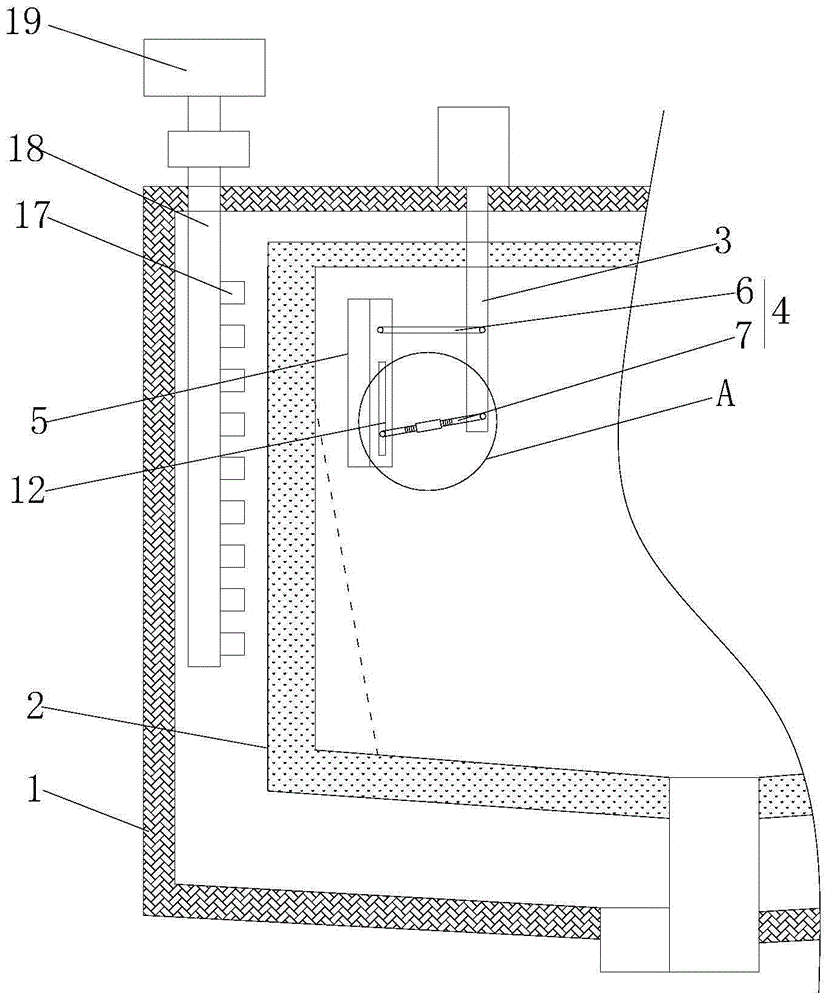

On-line detection device for water content of machine-made sand

PendingCN109269936AAffect accuracyThe calculation result is accurateWeighing by removing componentMan machineEngineering

The invention provides an on-line detection device for the water content of machine-made sand. The on-line detection device comprises a shell, a support, a sampling device, a drying device, a weighingdevice, a turnover device, a control device and a man-machine interactive device, wherein the support is arranged in the shell; the man-machine interactive device is arranged on the outer side of theshell; the sampling device is arranged on the inner side of the shell so as to obtain a machine-made sand sample and input the machine-made sand sample into the drying device; the drying device is arranged below the sampling device so as to receive and dry the machine-made sand sample; the weighing device is connected with the drying device so as to obtain the mass of the machine-made sand samplebefore being dried and the mass of the machine-made sand sample after being dried; the turnover device is arranged between the support and the drying device, so that after the machine-made sand sample is dried, the drying device is overturned downwards and restored; the control device communicates with the sampling device, the drying device, the weighing device, the turnover device and the man-machine interactive device. The water content of the machine-made sand is automatically detected and monitored in real time, operation is convenient and fast, the work efficiency is improved, and miscalculation is prevented.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

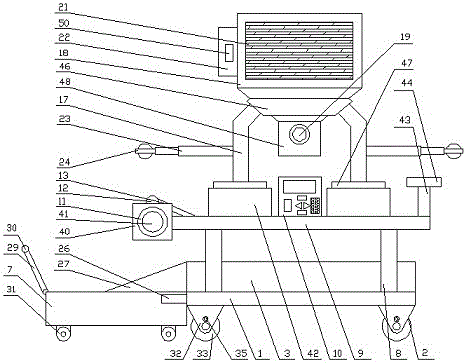

Sand screening device with automatic feeding and discharging functions

ActiveCN105710032AGood screening effectReduce frictionSievingScreeningElectric machineryElectric energy

The invention discloses a sand screening device with the automatic feeding and discharging functions. The sand screening device comprises a base frame. An edge baffle and a pressure sensor are arranged on the upper portion of the base frame. A multi-stage oil cylinder is arranged on one side of the base frame and matched with a discharging plate. The base frame is connected with a middle frame through a set of stand columns. A controller is arranged in the middle of the middle frame. A sand screening motor is arranged at one end of the middle frame and matched with a screen. The middle frame is matched with a feeding hopper through a support. A feeding motor is arranged on the lower portion of the feeding hopper and matched with a feeding wheel. A solar cell panel and an accumulator are arranged on the upper portion of the feeding hopper. The accumulator is electrically connected with lighting lamps at the ends of an extending-and-contracting rod. The electric sand screening manner is adopted in the sand screening device with the automatic feeding and discharging functions, automatic sand screening and discharging can be achieved, the workload of construction workers is relieved greatly, the sand screening quality is guaranteed while efficiency is improved, the solar lighting function is achieved, and part of electric energy is saved.

Owner:山西宏厦建筑工程第三有限公司

Discharge device adjustable centrifugal machine

The invention provides a discharge device adjustable centrifugal machine which comprises a chassis, a rotating drum, an inner discharge device and an outer discharge device, wherein the rotating drum is rotationally mounted in the chassis and is driven to rotate by a first driving device; the inner discharge device comprises a second driving device, a driving rod, a connecting assembly and a cutter assembly; the driving rod stretches into the rotating drum from the upside; the second driving device drives the driving rod to move up and down; the outer discharge device comprises a vent pipe stretching into a part between the chassis and the rotating drum; a plurality of nozzles are formed on the vent pipe; the vent pipe is communicated with a blower; the nozzles face towards the rotating drum; the cutter assembly comprises a cutter rest, a cutter and a hair brush; and the cutter and the hair brush are respectively arranged on the two sides of the cutter rest. The discharge device adjustable centrifugal machine discharges more easily and cleanly, and the service life is increased.

Owner:湖南捷瑞化工有限公司

Rotary electroplating machine and automatic discharger thereof

The invention discloses a rotary electroplating machine and an automatic discharger thereof. The rotary electroplating machine, which is used for electroplating and discharging chip elements, comprises a cathodal ring, a cathodal ring-rotating mechanism and the automatic discharger, the cathodal ring is controlled by the cathodal ring-rotating mechanism to rotate, the automatic discharger comprises a base plate and an automatic separating mechanism, and the base plate and the cathodal ring are controlled by the automatic separating mechanism to be closed and be separated from each other. Because the rotary electroplating machine utilizes the automatic separating mechanism to control the closing and separation between the base plate and the cathodal ring, the rotary electroplating machine can electroplate and discharge chip elements; during electroplating, the cathodal ring and the base plate are closed; when materials need to be discharged, the cathodal ring and the base plate are separated from each other, so that a gap is formed, as a result, the chip elements can be thrown out from the gap along with water flow during rotation, consequently, the step of automatic discharge is complete, and the materials can be discharged thoroughly.

Owner:SHENZHEN SUNLORD ELECTRONICS

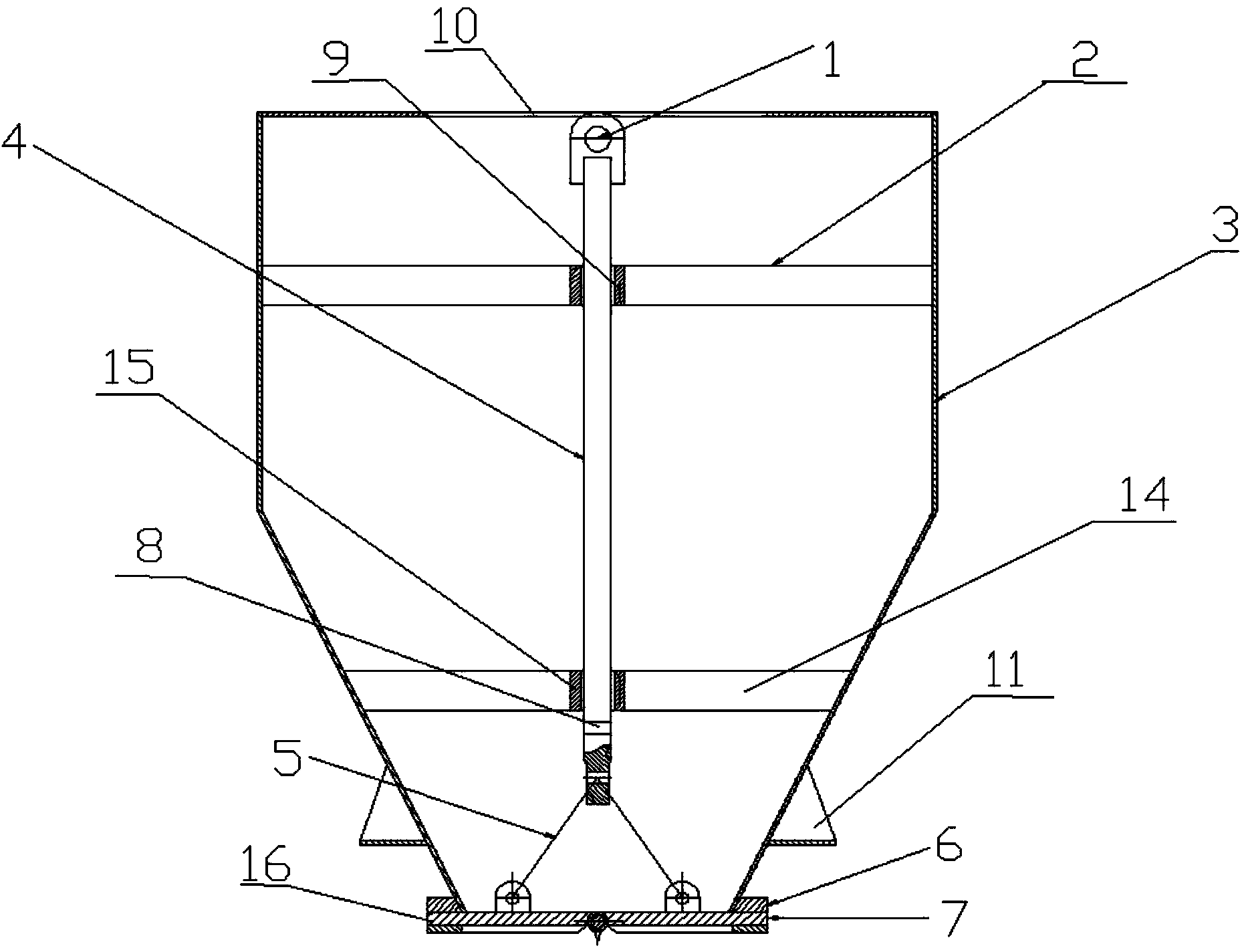

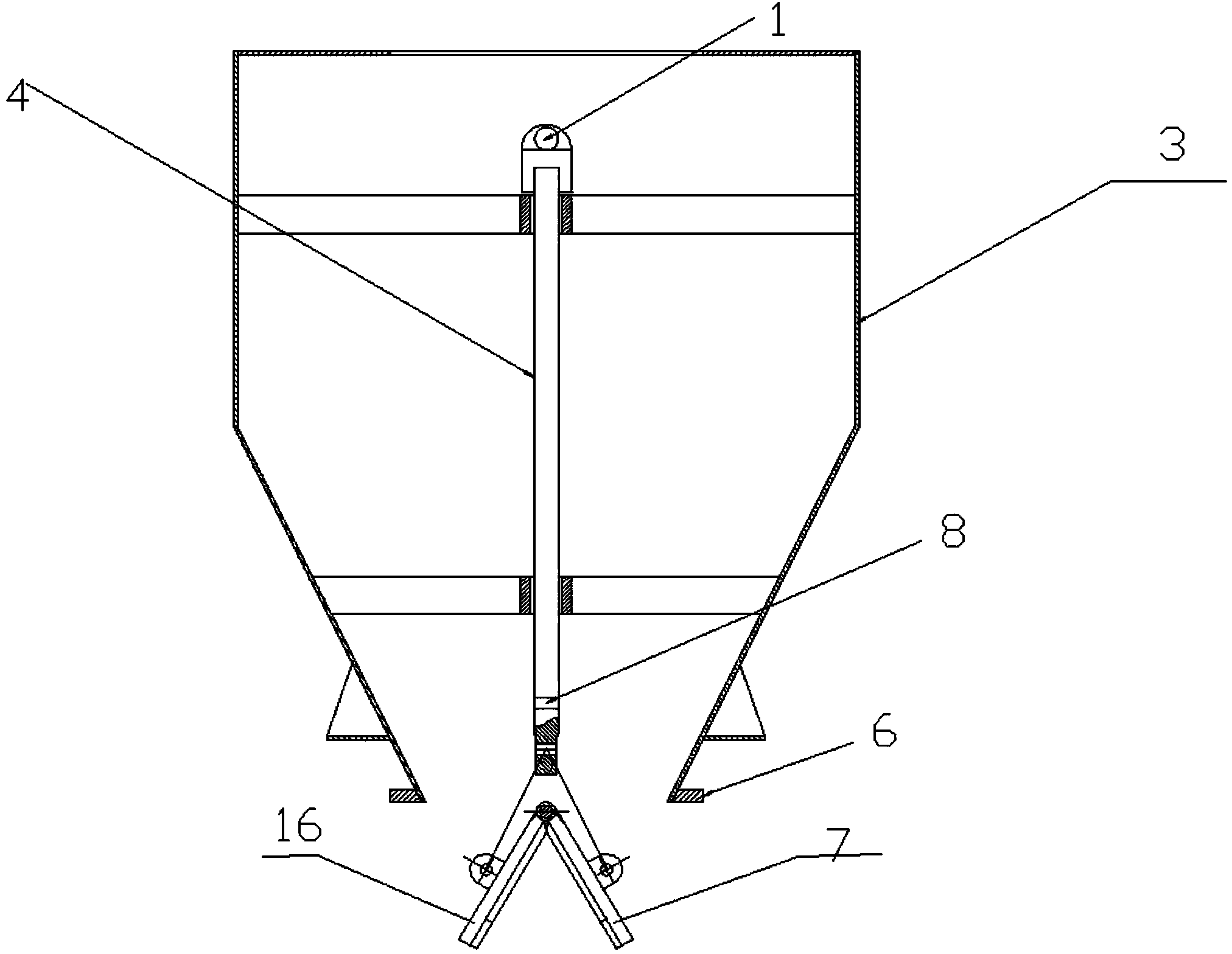

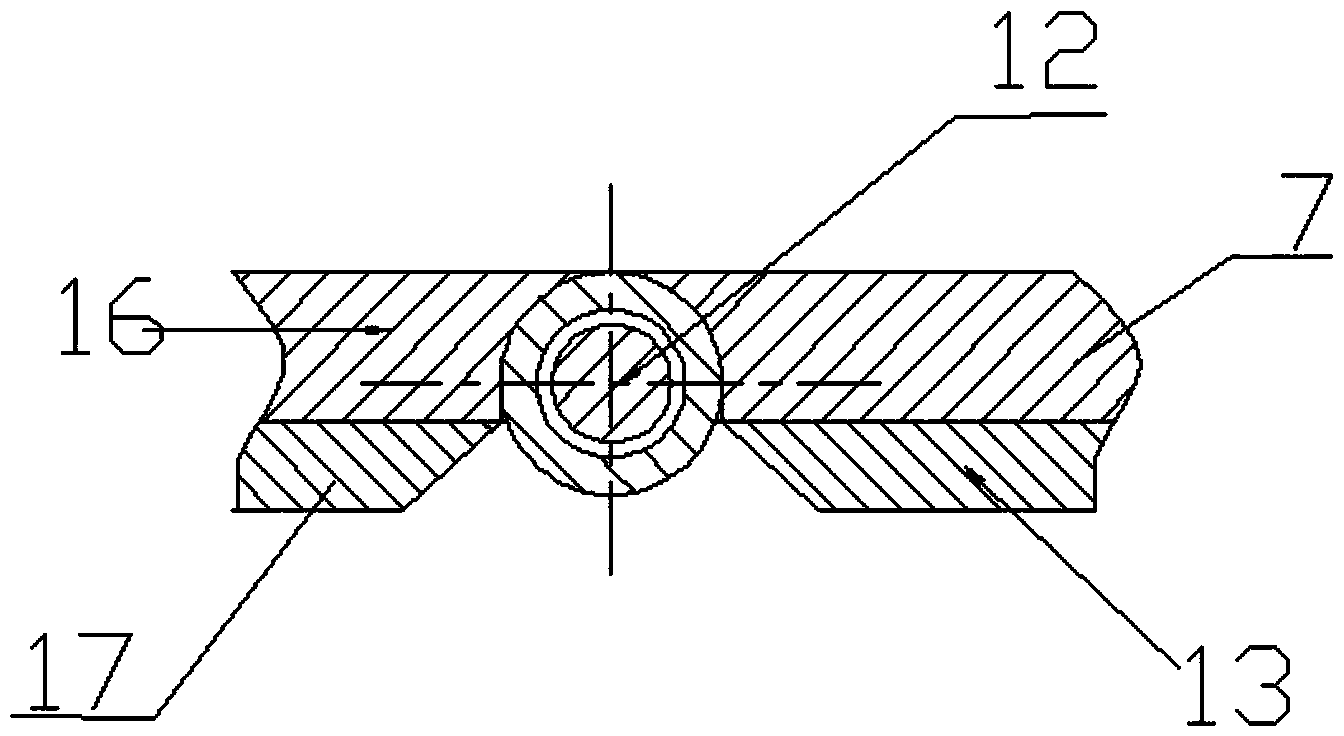

Automatic feeding tank

InactiveCN104029290ASimple structureUnload cleanLarge containersAuxillary shaping apparatusEngineeringDead weight

The invention relates to the technical field of material feeding automation equipment, and discloses an automatic feeding tank. The automatic feeding tank comprises a tank body. A positioning plate with a through hole formed in the center is arranged in the tank body, a hanging and pulling rod is arranged in the center of the tank body, one end of the hanging and pulling rod penetrates the through hole, a hanging hook hole is formed in the upper end of the hanging and pulling rod, a discharge port can be in sealed contact connection with a first loose-leaf movable turning plate and a second loose-leaf movable turning plate, a center shaft is connected between the first movable turning plate and the second movable turning plate in a rotating mode, and the hanging and pulling rod is connected with the first movable turning plate and the second movable turning plate through two steel wire ropes. The automatic feeding tank is simple and practical in structure, little in dust and safe to operate, and integrates loading, transportation and automatic discharging; materials are discharged thoroughly, the materials are discharged by using the dead weight of the materials, and sealing is achieved through the movable turning plates.

Owner:ANHUI PROVINCE XIAO COUNTRY HUALONG REFRACTORY MATERIALS

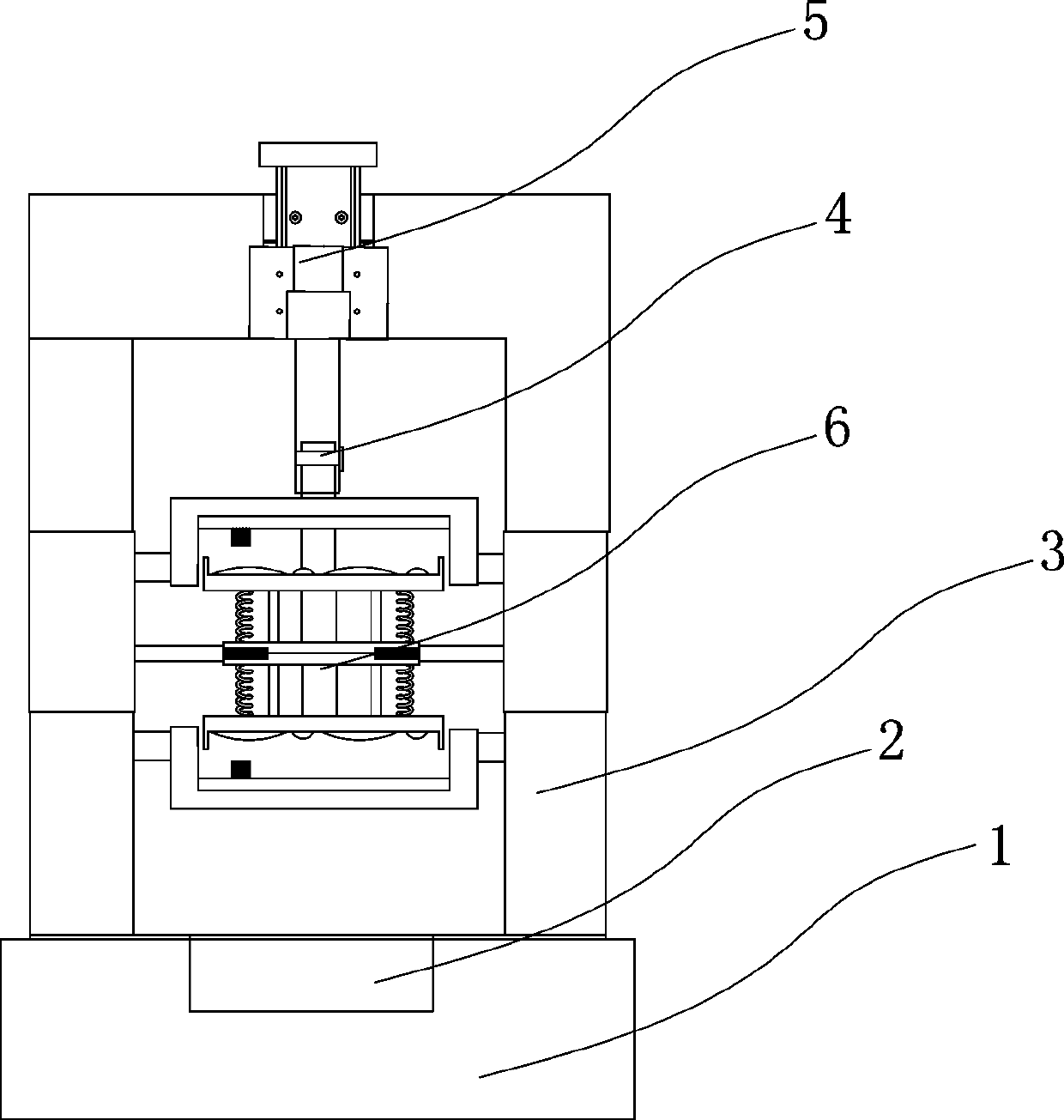

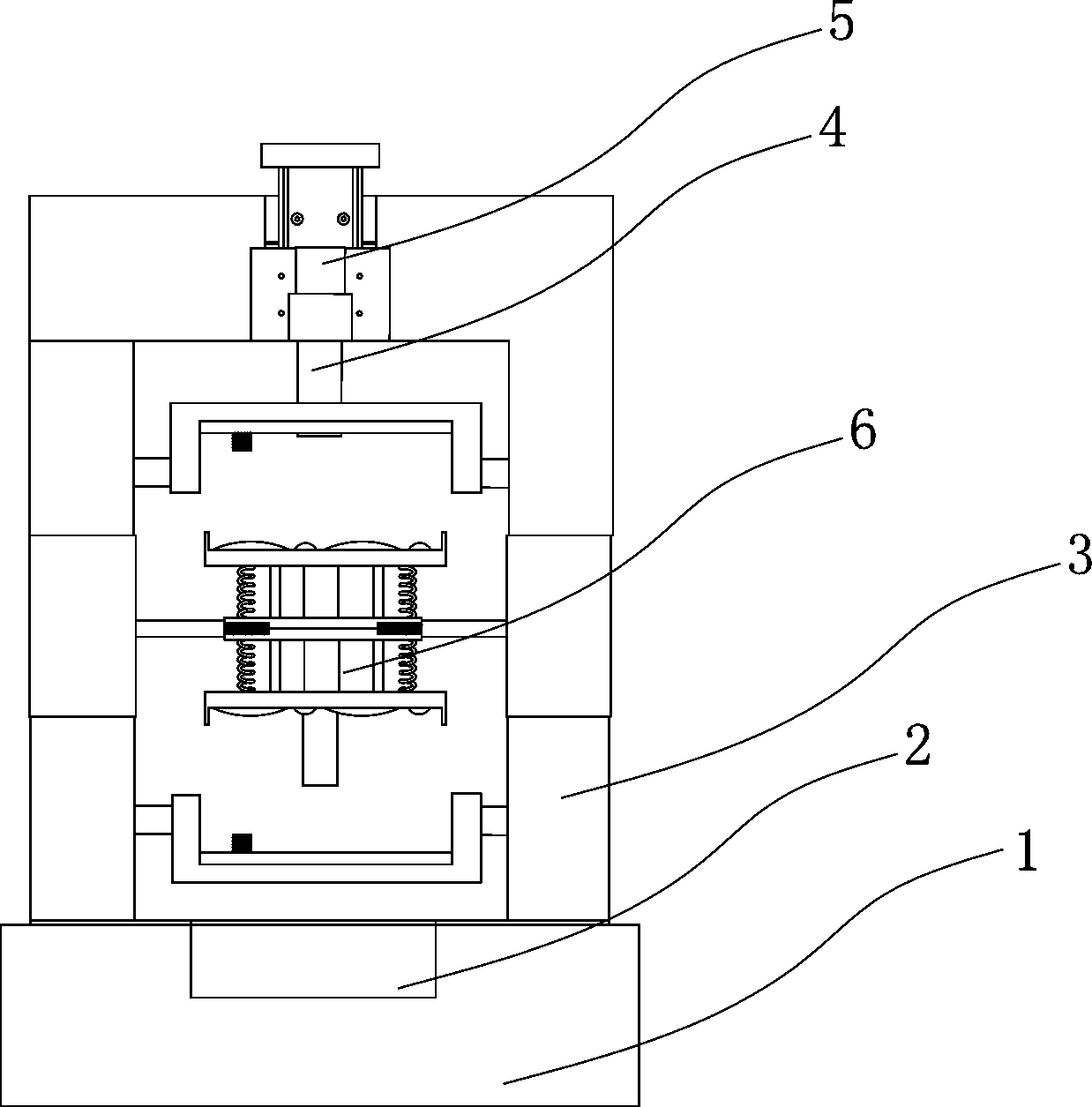

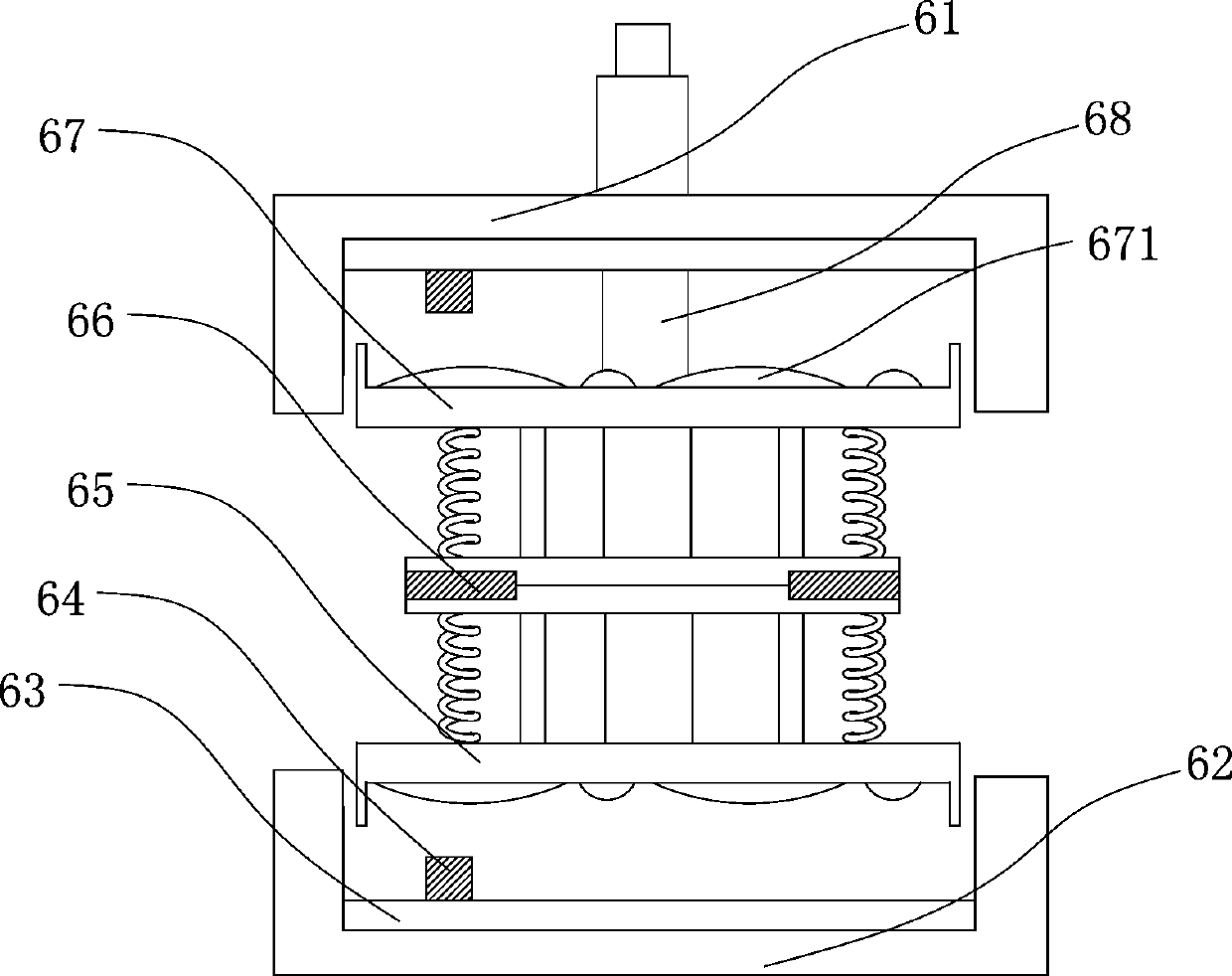

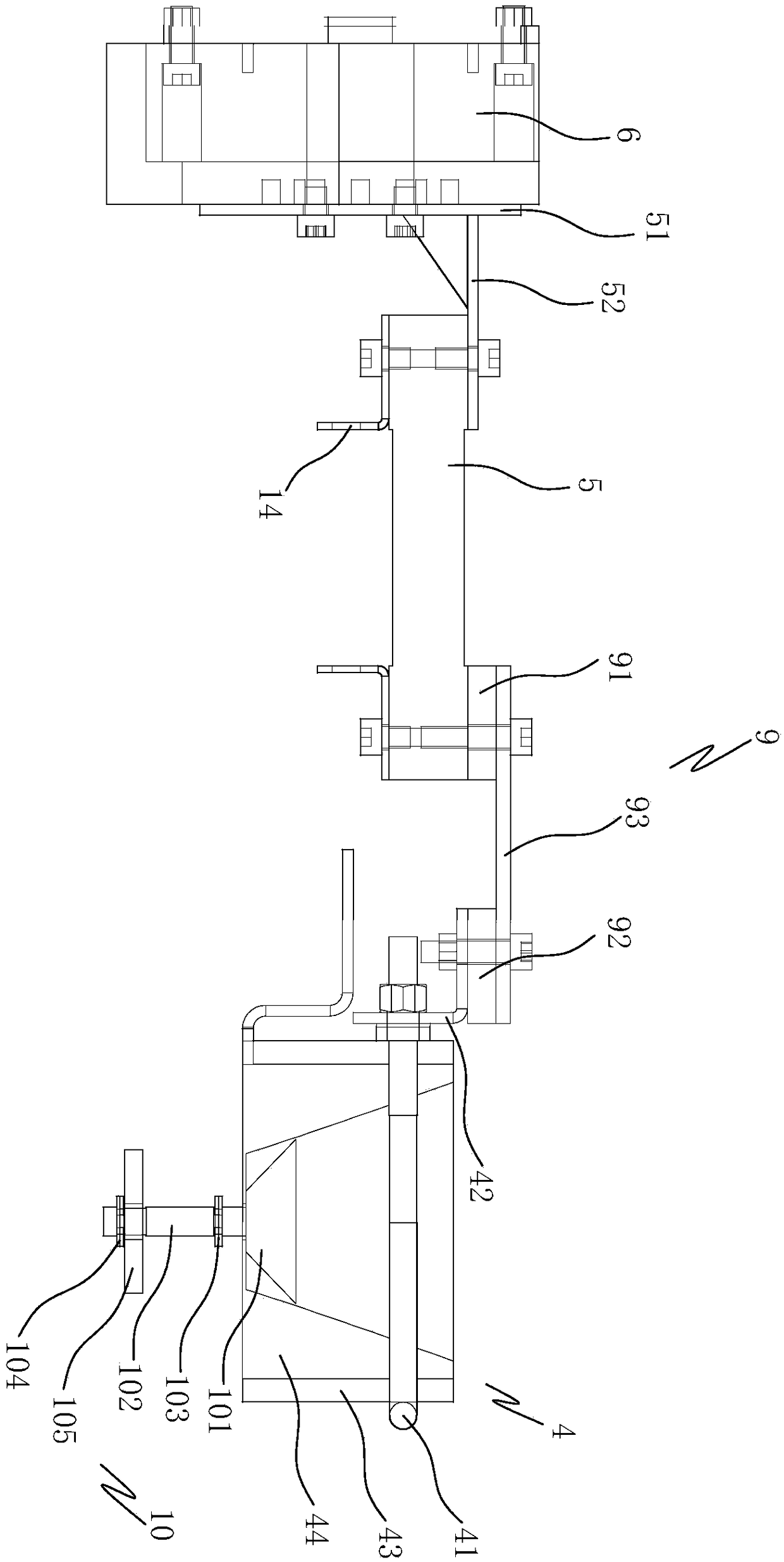

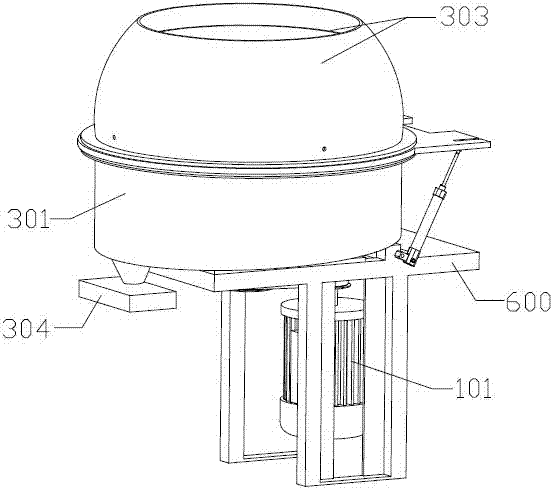

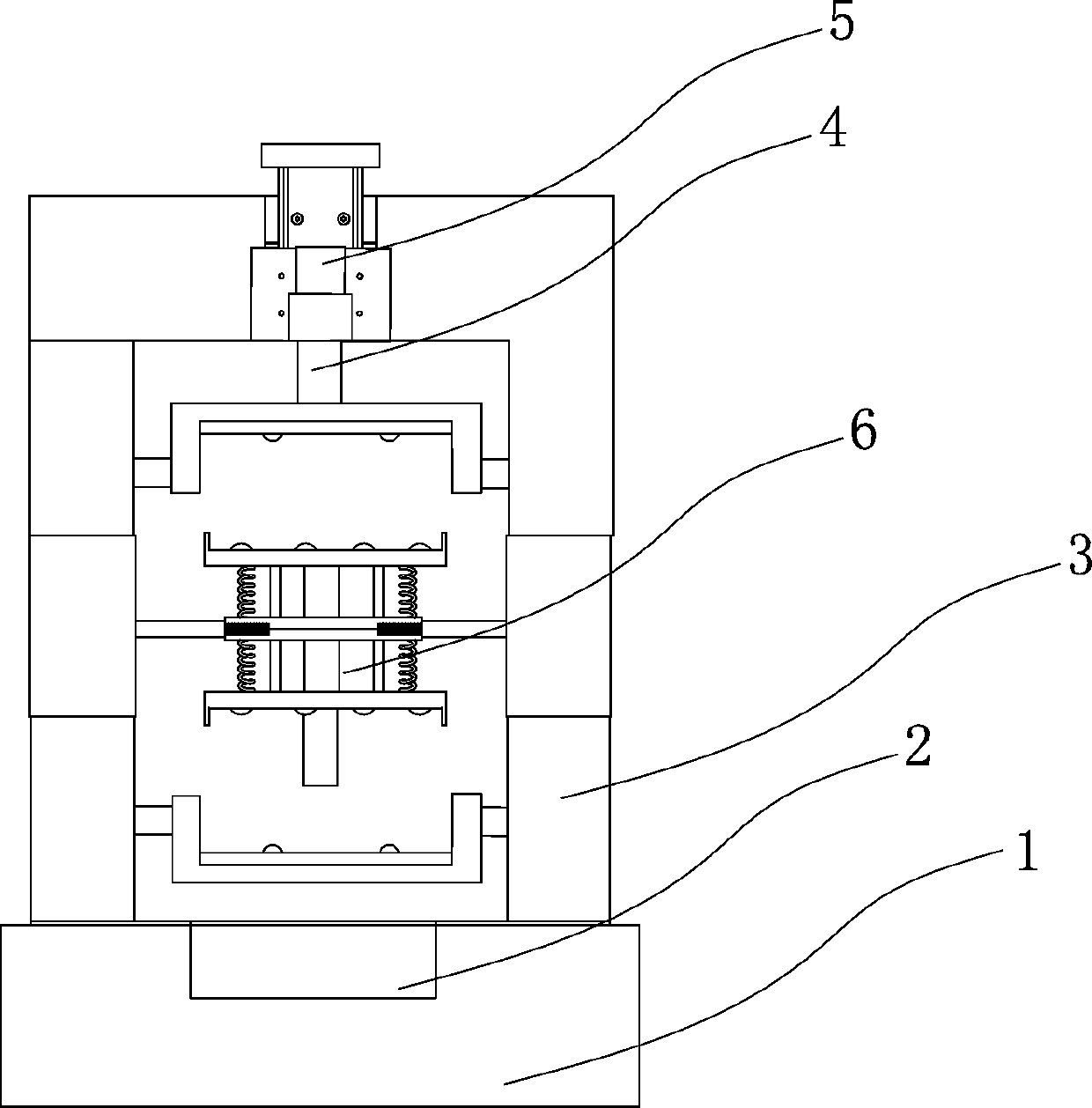

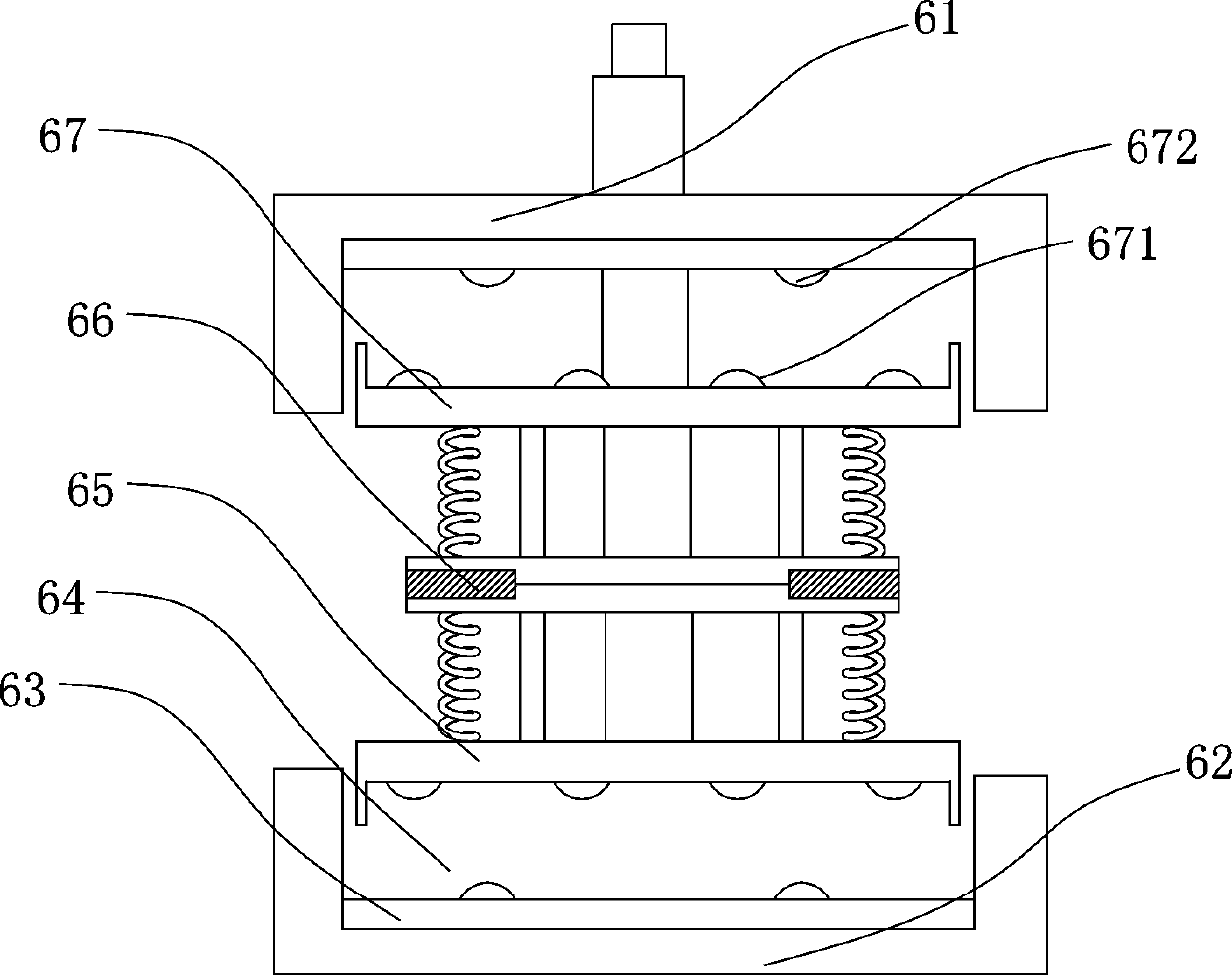

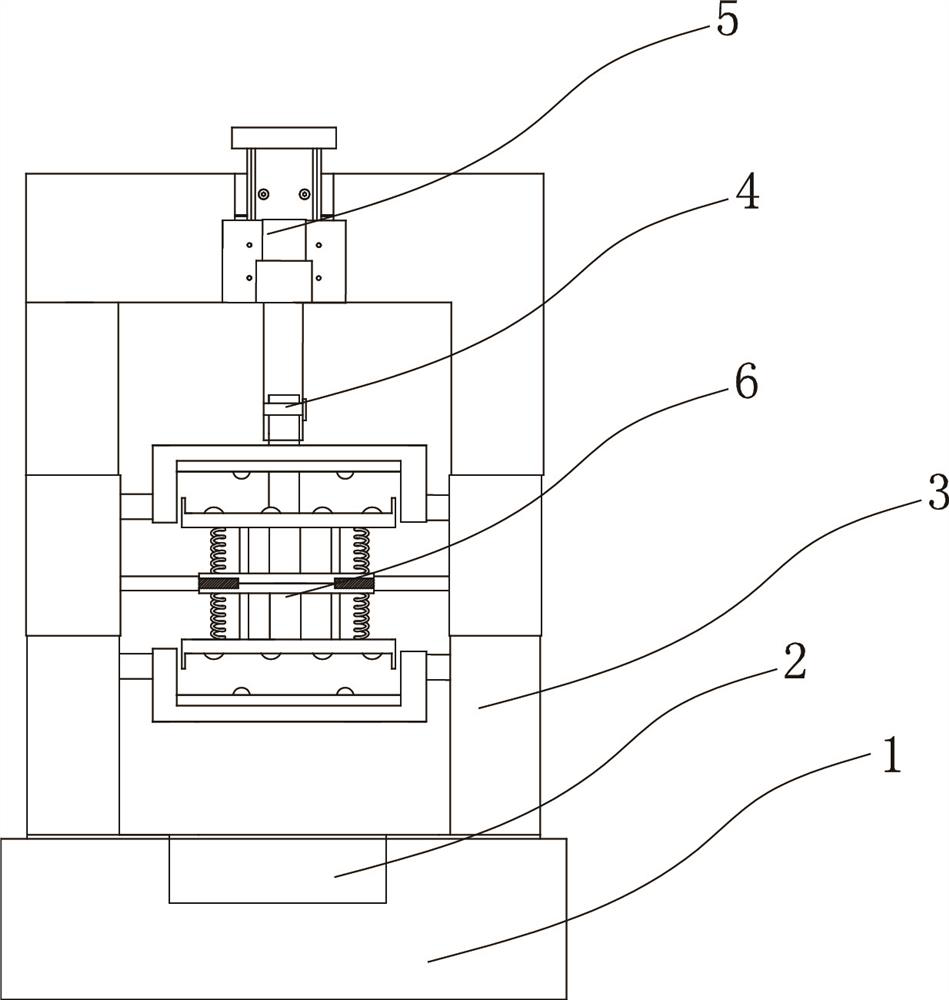

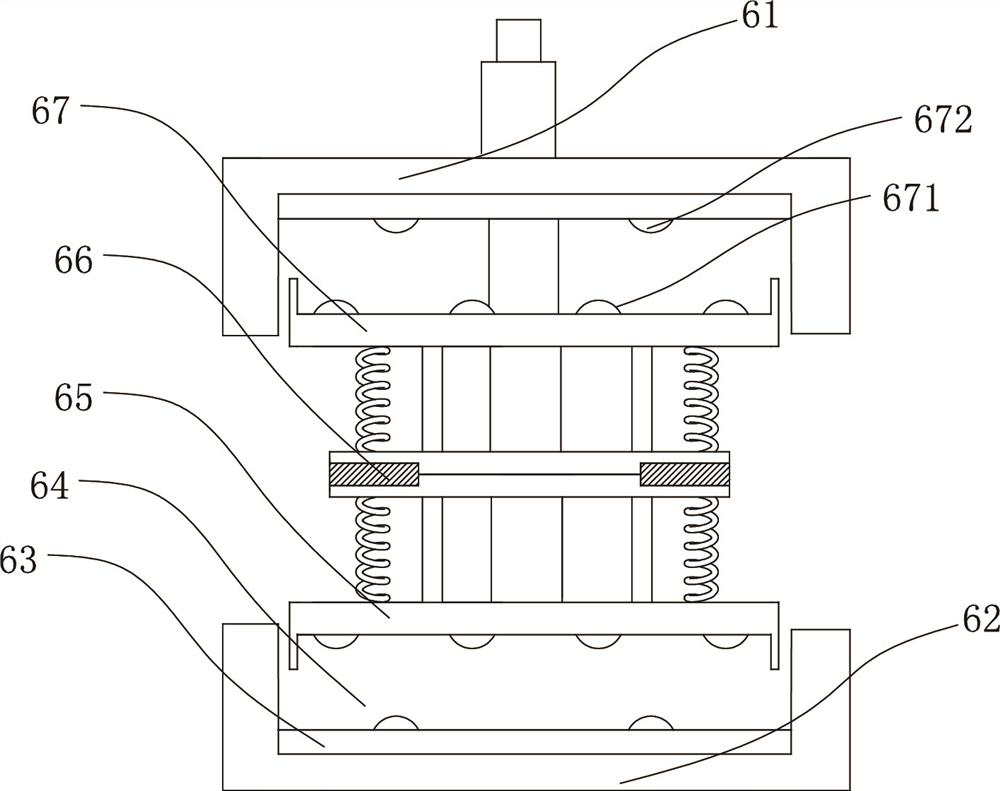

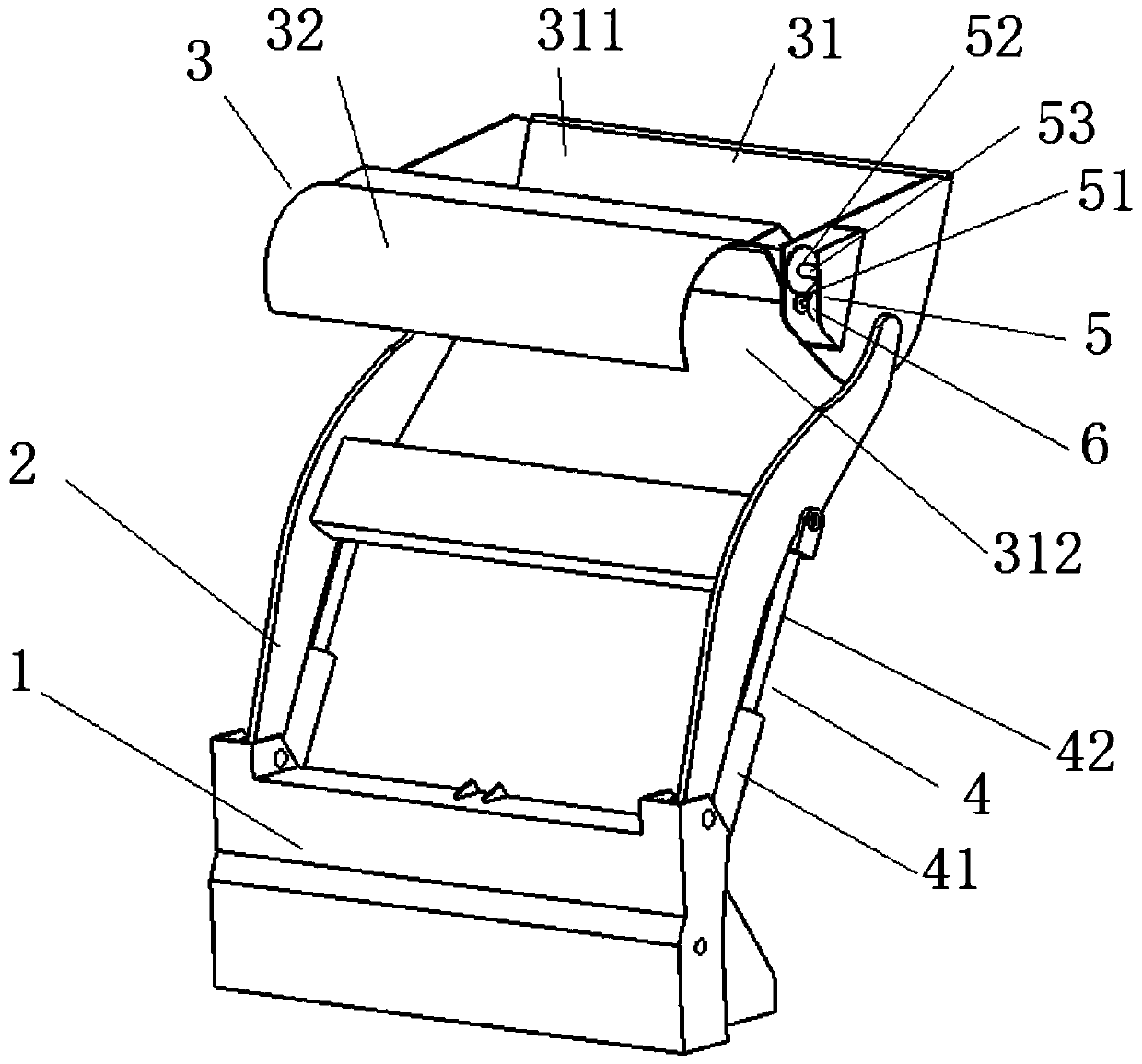

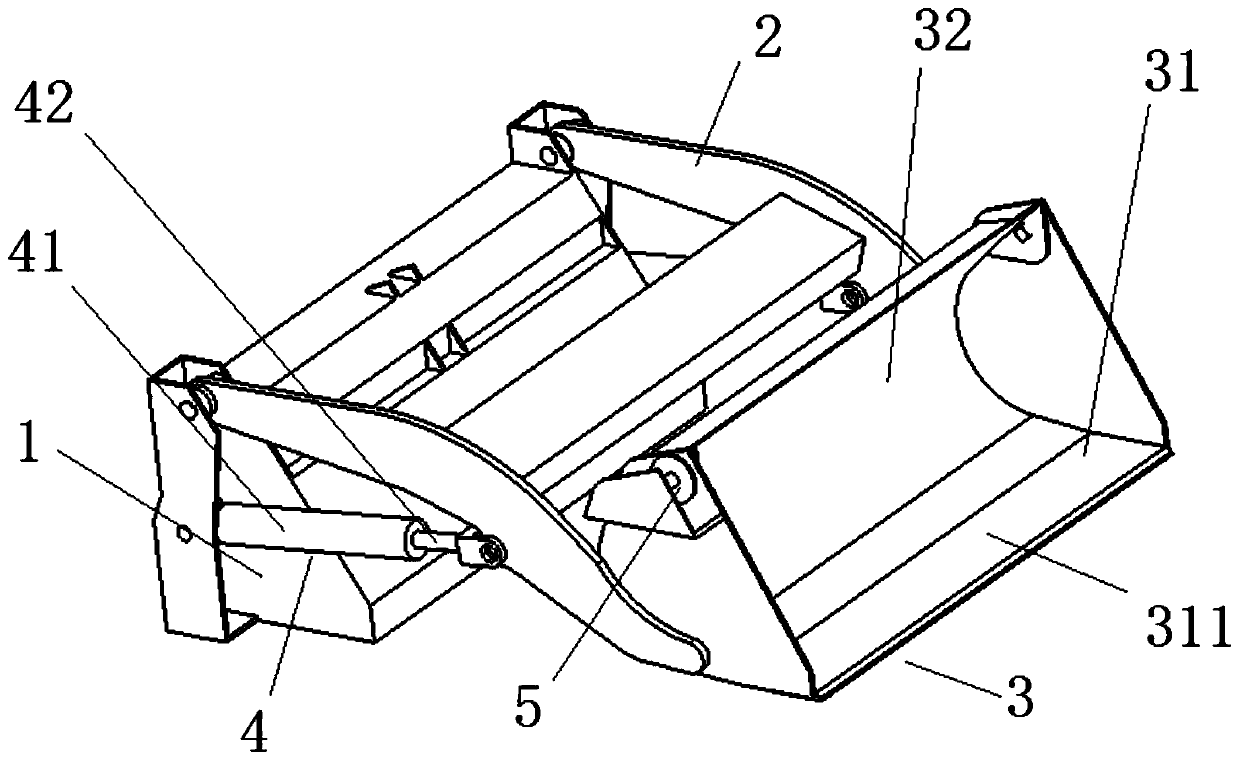

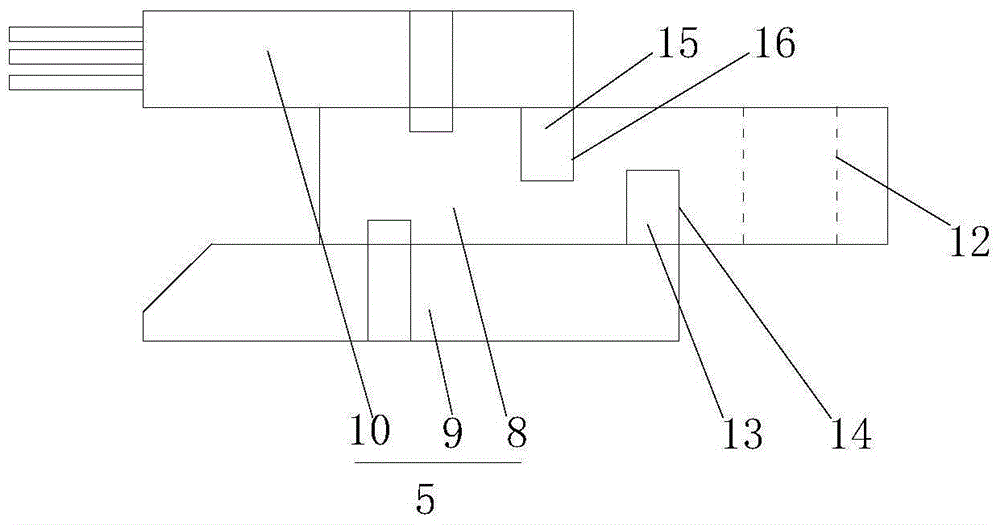

Double-layer tealeaf twisting machine

InactiveCN107549367AImprove efficiencyUnload cleanPre-extraction tea treatmentHydraulic cylinderEngineering

The invention relates to a double-layer tealeaf twisting machine. The double-layer tealeaf twisting machine comprises a foundation support, wherein the foundation support is provided with a support, the end portion of the support is provided with a hydraulic cylinder, the lower end of the hydraulic cylinder is provided with a mechanical claw, the mechanical claw grabs a twisting mechanism, the twisting mechanism comprises an upper shell and a lower shell, two sides of the upper shell and the lower shell are connected with a fixed rod, the other end of the fixed rod is fixedly connected with the support, two sides of the support are respectively provided with a slide rail, the fixed rod slides on the slide rails, the inner sides of the upper shell and the lower shell are provided with a middle seat, and the upper side and the lower side of the middle seat are respectively provided with an upper disc and a lower disc. The double-layer tealeaf twisting machine has the following beneficialeffects that: the upper disc and the lower disc separately twist tealeaves of different sizes or different types of tealeaves, so that the efficiency is high, materials do not need to be manually loaded and poured, and the materials can be thoroughly unloaded.

Owner:宁波市晶杰国际物流有限公司

Solid and liquid separator for materials

ActiveCN103657176BImprove stressThe moisture content of solids is reducedFiltration separationPush and pullLocking mechanism

The invention discloses a solid and liquid separator for materials. The solid and liquid separator comprises a frame, press plates, filter plates, a push-and-pull locking mechanism, a filter cloth mechanism, a filter cloth regeneration mechanism and a cleaning mechanism which are arranged on the frame, wherein the press plates and the filter plates are arranged on the frame in a sliding way alternately, and are matched to extrude a material, so that solid and liquid of the material can be separated; the push-and-pull locking mechanism is used for locking, pushing away all the press plates and filter plates, so that solid-liquid separation operation can be performed, or the material can be discharged; the filter cloth mechanism is used for separating solid and liquid of the material when the material is extruded; the filter cloth regeneration mechanism is used for washing to regenerate the filter cloth after the material is discharged; the cleaning mechanism is used for cleaning the material attached to the separator after solid and liquid of the material are separated. The solid and liquid separator has the characteristics of reasonable design, high structure strength, convenience in operation, complete solid and liquid separation, high separation efficiency, convenience in cleaning, long service life, log maintenance frequency, high reliability, strong practicality and the like, and is beneficial for greatly increasing production benefit of enterprises.

Owner:四川宝凯鑫诚环保科技有限公司

Heatable storage system with an insulation combination and usage method

ActiveCN102730348ARealize integrationIncrease usageLarge containersTank wagonsHeat conductingEngineering

The invention relates to a heatable storage system with an insulation combination. The heatable storage system comprises a plurality of storage containers. The storage container mainly comprises a heating pipe, a heat medium inlet, a heat medium outlet, two material feeding and discharging holes, a material connecting pipe and a heat medium connecting pipe, wherein the heating pipe is arranged at the bottom of the inner part of an inner shell and a heat-conducting medium is arranged in the heating pipe and is used for heating materials in the storage containers; both ends of the heating pipe separately pass through the heat medium inlet and the heat medium outlet which are formed on the shell; the two material feeding and discharging holes are both formed in the shell; one end of the material connecting pipe is used for connecting one material feeding and discharging hole formed in the shell and the other end of the material connecting pipe is used for connecting the other material feeding and discharging hole formed in the adjacent shell; and one end of the heat medium connecting pipe is connected with the heat medium outlet on the shell and the other end of the heat medium connecting pipe is connected with the heat medium inlet on the adjacent shell. The integration of feeding and discharging materials and heating is realized by the heatable storage system with insulation combination.

Owner:TIANJIN ZHAOHUA LOGISTICS CO LTD

Flap gate for scraper

Owner:扬州正大机械制造有限公司

Polyurethane mixing and stirring mechanism

The invention discloses a polyurethane mixing and stirring mechanism which comprises a fixed rack, a heating rod, a fixed box, a loop bar, an arc-shaped scraper blade and a switching valve, wherein astirring barrel is mounted in the fixed rack, a connecting plate is mounted in the stirring barrel, the loop bar is mounted in the connecting plate through a bearing, a third cone-shaped gear is mounted at the top end of the loop bar, the fixed box is mounted at the top end of the stirring barrel, a motor is arranged in the fixed box, an output end of the motor is provided with a rotating shaft penetrating the loop bar through a coupling, a first cone-shaped gear is mounted on the outer wall of the rotating shaft, and first stirring rods are mounted in an equally spaced manner on the outer wall of the loop bar. According to the polyurethane mixing and stirring mechanism, the motor is started to drive the rotating shaft and the loop bar to rotate reversely, so that it is convenient to drivethe first and second stirring rods to mix the polyurethane mixture in the stirring barrel, and therefore, the stirring effect is better.

Owner:JIANGSU MIAOHONG ENVIRONMENTAL PROTECTION NEW MATERIAL TECH CO LTD

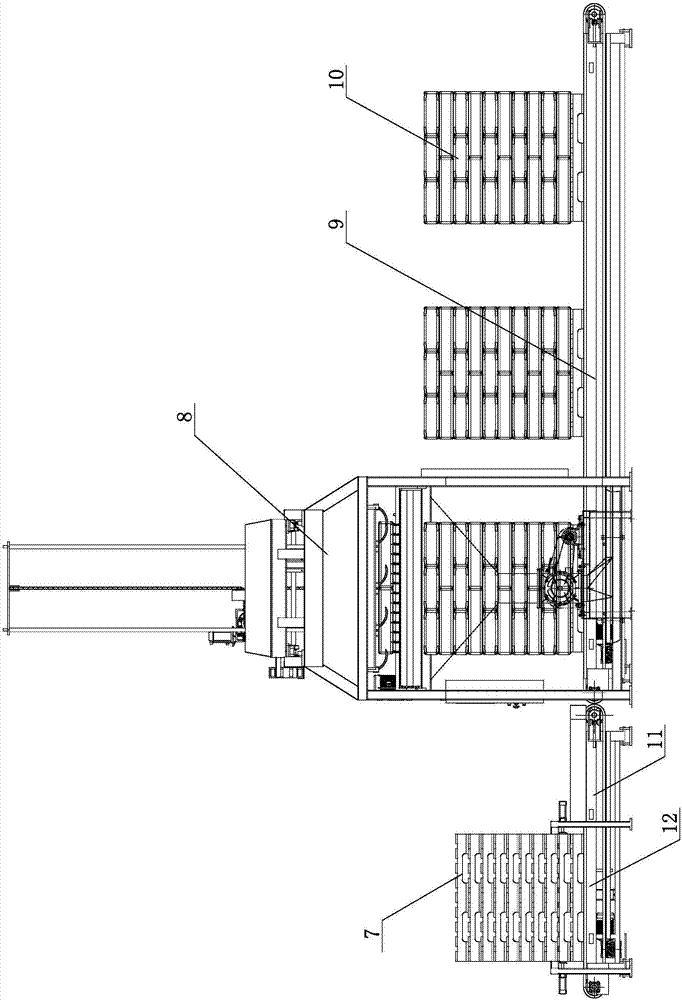

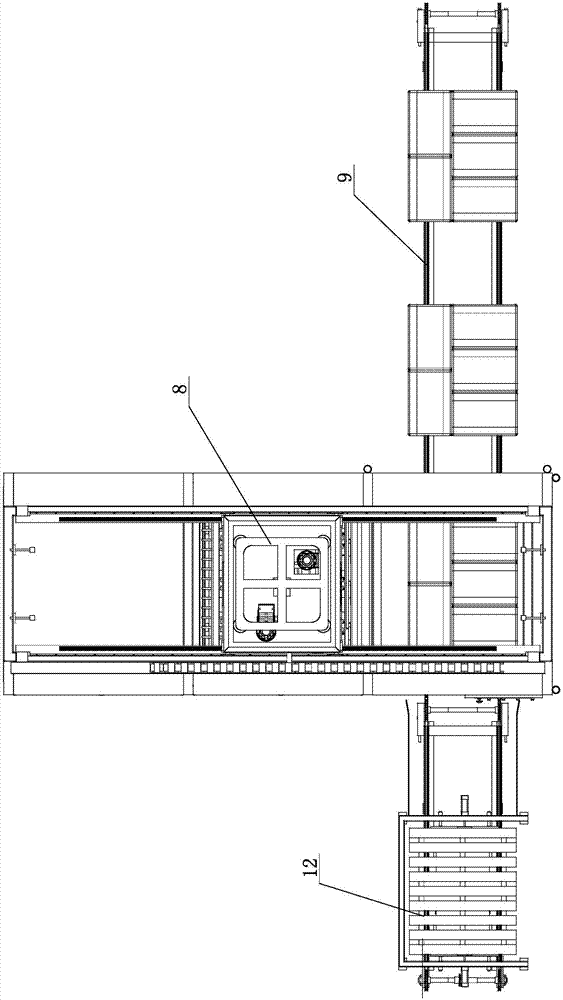

Automatic flipping unloading system and its unloading method in garbage transfer station

The invention discloses a rubbish transfer station automatic turn-over unloading system. The system comprises a turn-over unloading device, a rubbish collecting box provided with an upper opening unloading door and a rubbish conveying truck used for conveying the rubbish collecting box provided with the upper opening unloading door. The automatic turn-over unloading system can guarantee that pollution to surroundings is avoided in the process of conveying rubbish to a transfer station, the environmental protection is better, automatic unlocking and unloading at the transfer station is achieved, manual operation is not needed, and the unloading efficiency is high. During unloading, the rubbish is completely unloaded and not prone to be suspended and retained, and labor intensity of manual work is effectively relieved. The invention further discloses an unloading mode through the rubbish transfer station automatic turn-over unloading system. By means of the unloading mode, turn-over unloading can be automatically finished, and the labor intensity of manual work is effectively relieved.

Owner:CHONGQING ENDURANCE & SHINMAYWA IND

A kind of aluminum sol production method

ActiveCN106268549BReduce investmentFully control the reaction rateAluminium chloridesSol preparationChemical industryHydrogen

The invention relates to the technical field of chemical industry and in particular relates to an aluminum soil production method. A single-kettle charge production manner is adopted; a reaction kettle internally comprises a stock bin for containing an aluminum source; in a production process, the aluminum source is added into the stock bin and the first part of diluted hydrochloric acid is added into a kettle body, wherein the adding amount is one-tenth to one-third of the total mass; the diluted hydrochloric acid reacts with the aluminum source at the lower part of the stock bin; after reaction temperature is stabilized to 60 DEG C to 80 DEG C, the temperature is kept for 15min to 30min; then the second part of diluted hydrochloric acid is slowly added; after the reaction temperature reaches 85 DEG C to 100 DEG C, the third part of diluted hydrochloric acid is slowly added; the reaction temperature is stabilized to 85 DEG C to 100 DEG C through the speed of adding the third part of diluted hydrochloric acid; after reaction is carried out for 12h to 20h, aluminum soil with the Al / Cl mass ratio of 1.0 to 2.0 and the pH (Potential of Hydrogen) of 2.4 to 3.2 is finally obtained, and total acid adding time is controlled to be 3h to 10h. According to the aluminum soil production method, an intermittent production process is adopted and a normal-pressure spontaneous reaction is carried out; a reaction speed is sufficiently controlled in a reaction process and spontaneous heat generated by the reaction is reasonably utilized; in a whole production process, stirring and steam heating are not needed, so that the energy consumption can be reduced by 80 percent or more when being compared with that of a traditional production process.

Owner:REZEL CATALYSTS CORP

Garbage transferring box and garbage cleaning system

PendingCN108529100ARealize the collectionEffective classificationWaste collection and transferRefuse receptaclesRefuse collectionLitter

The invention relates to the technical field of garbage cleaning movement, in particular to a garbage transferring box and a garbage cleaning system. The garbage transferring box comprises a wet garbage collecting box and a dry garbage collecting box which are connected side by side in the longitudinal direction, a wet garbage putting opening is arranged on a first upper top plate of the wet garbage collecting box, and a wet garbage unloading door is hinged to the side wall of the first upper top plate to enable the wet garbage unloading door to be capable of closing or opening the wet garbagecollecting box; a dry garbage putting opening is arranged on a second upper top plate of the dry garbage collecting box, and a dry garbage unloading door is hinged to the side wall of the second upper top plate to enable the dry garbage unloading door to be capable of closing or opening the dry garbage collecting box; and an unloading pushing and pressing device is arranged on the dry garbage collecting box and can push garbage in the dry garbage collecting box. By means of the garbage transferring box, the technical problem that an existing garbage transferring box cannot effectively classify garbage, and consequently garbage treatment is difficult is solved.

Owner:江苏三迪机车制造有限公司

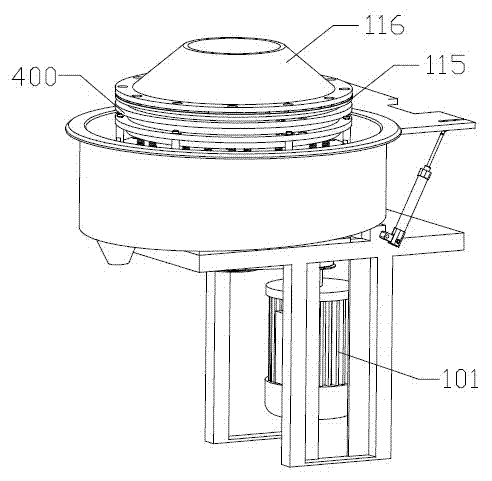

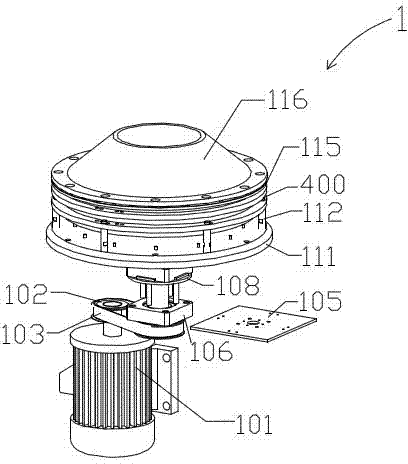

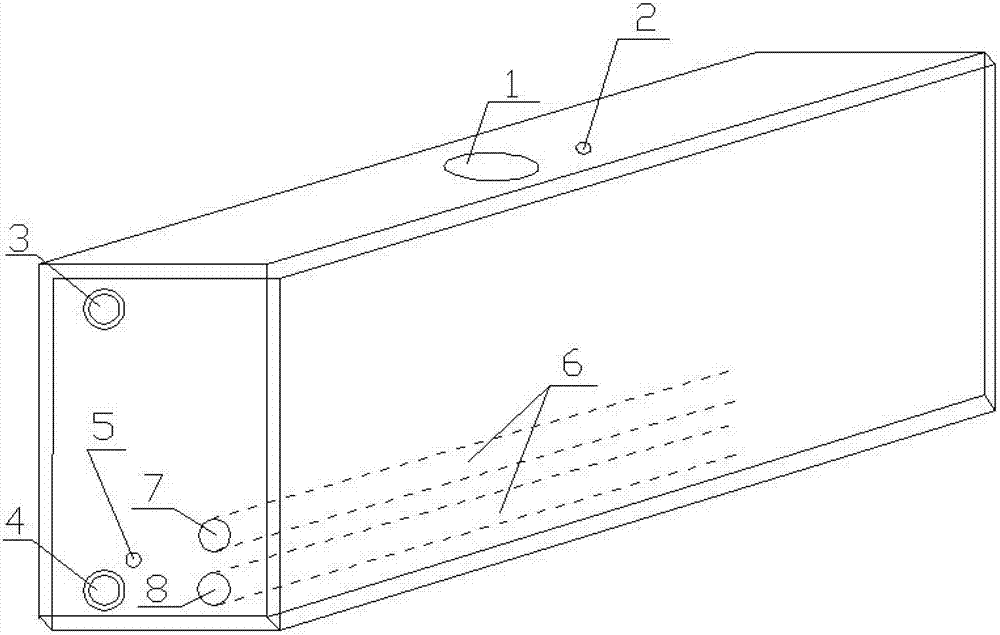

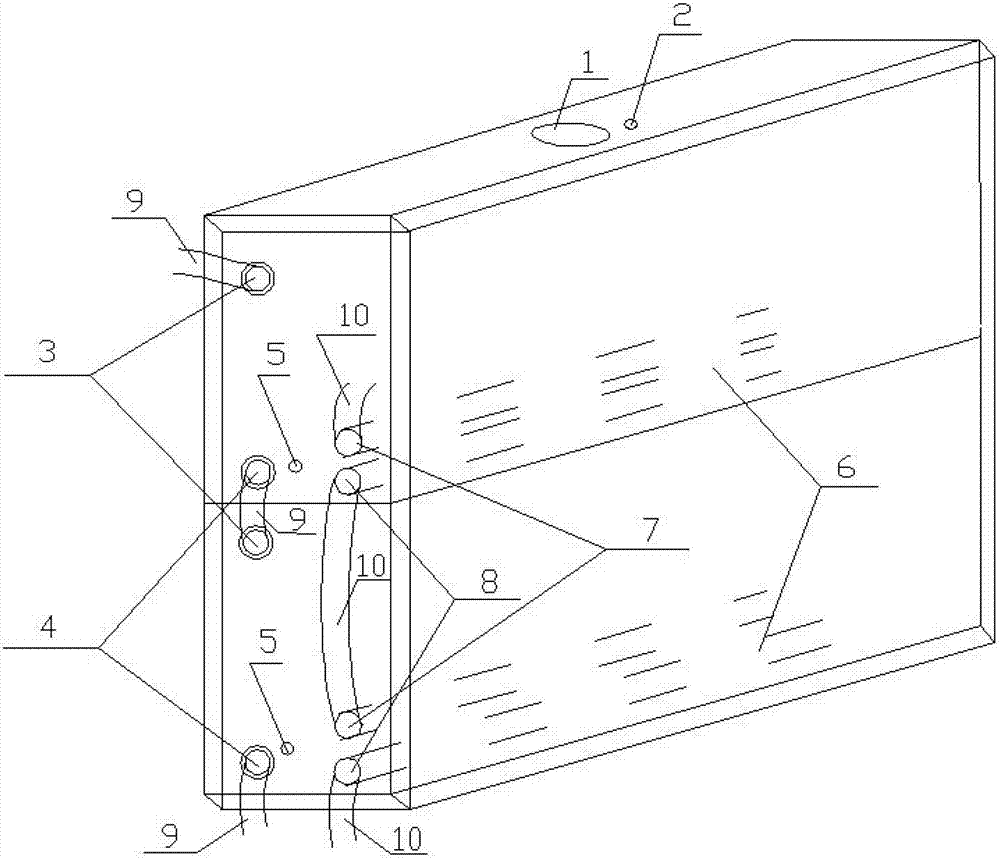

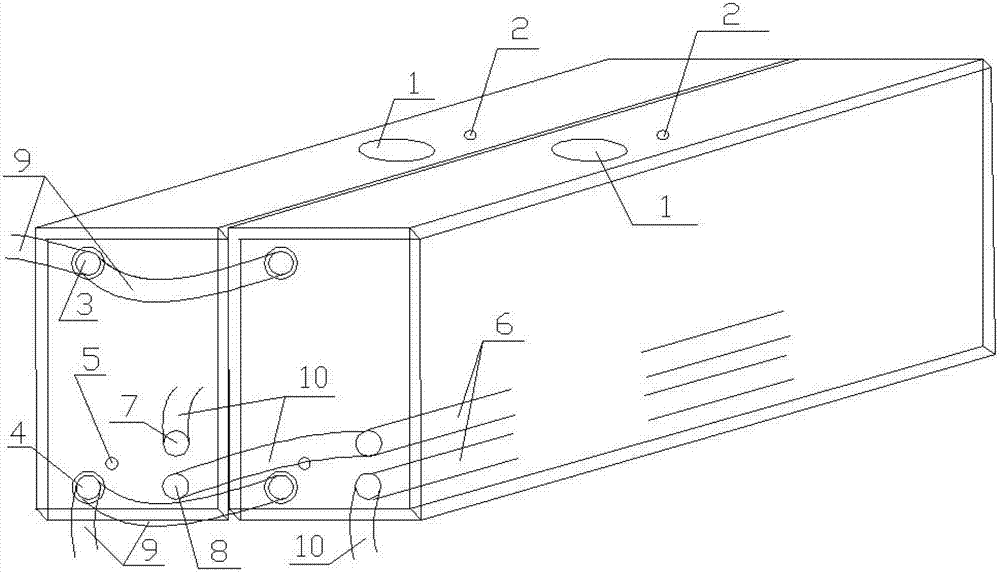

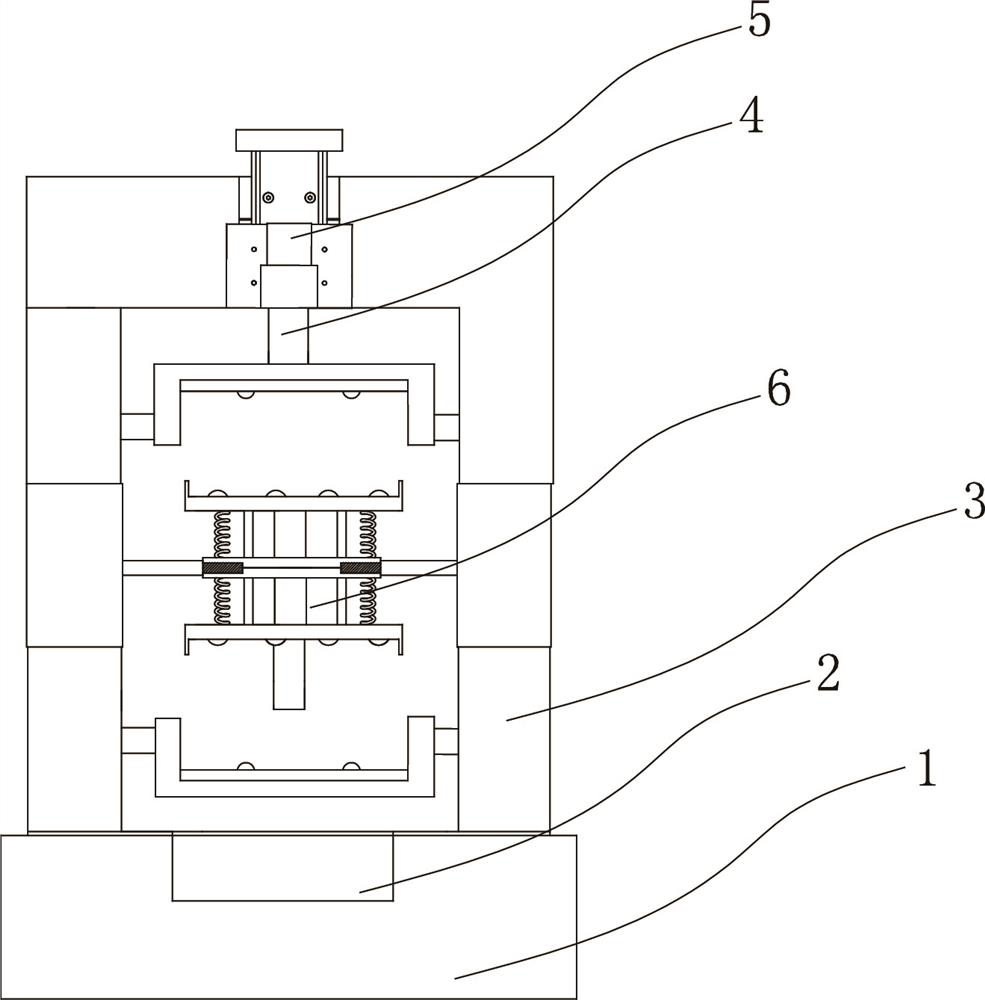

A double-layer tea rolling machine

ActiveCN107518111BImprove efficiencyUnload cleanPre-extraction tea treatmentHydraulic cylinderAgricultural engineering

The invention relates to a double-layer tea leaf twisting machine. The double-layer tea leaf twisting machine comprises a base, wherein a bracket is arranged on the base; a hydraulic cylinder is arranged at the end part of the bracket; a manipulator is arranged at the lower end of the hydraulic cylinder, and is used for grabbing a rolling mechanism; the rolling mechanism comprises an upper housing and a lower housing; fixing rods are respectively connected to two sides of the upper housing and two sides of the lower housing, and the other end of each fixing rod is fixed to the bracket; sliding rails are arranged on two sides of the bracket; the fixing rods slide on the sliding rails; a middle seat is arranged on the inner side of the upper housing and the inner side of the lower housing; and an upper plate is arranged on the upper side of the middle seat, and the lower plate is arranged on the lower side of the middle seat. The double-layer tea leaf twisting machine disclosed by the invention has the following beneficial effects that the upper plate and the lower plate are separately used for rolling tea leaves of different sizes or tea leaves of different kinds; the efficiency is high; manual feeding and manual batch turning are not needed; and the discharging is thorough.

Owner:RIZHAO CHUNMING MACHINERY MFG

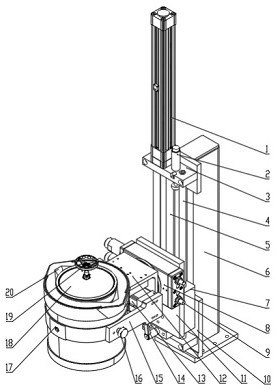

Automatic loading and unloading device for chemical liquid

PendingCN112537746AEasy to transportPrevent leakageLiquid bottlingBottle emptyingChemical industryStructural engineering

The invention relates to the technical field of chemical industry, in particular to an automatic loading and unloading device for chemical liquid. The automatic loading and unloading device comprisesa supporting seat, a lifting assembly, a rotating assembly, a fixing assembly, a storage tank and an upper cover. The lifting assembly is arranged at the front end of the supporting seat; the rotatingassembly is arranged at the front end of the lifting assembly; the fixing assembly is arranged at the front end of the rotating assembly; the storage tank is arranged in the fixing assembly; and theupper cover is arranged at the upper end of the storage tank. According to the automatic loading and unloading device provided by the invention, the lifting assembly and the rotating assembly are arranged; the lifting assembly controls the height of the storage tank according to the situation, and chemical liquid can be conveniently and exactly conveyed into the storage tank; the rotating assemblycan control the left-right inclination angle of the storage tank according to the situation, and the chemical liquid in the tank can be conveniently and better conveyed to an unloading device; and the automatic loading and unloading device has a relatively high automation degree in overall structure, saves time and efforts, and realizes complete unloading.

Owner:马鞍山神剑新材料有限公司

Working device of dump loader

ActiveCN107044143BSimple structureImprove work efficiencyMechanical machines/dredgersVehicle frameRocker arm

The invention discloses a working device of a self-discharge loading machine. The working device comprises a front frame, a movable arm, a bucket mechanism and a driving mechanism, wherein the front frame is arranged on the loading machine; the movable arm is movably arranged on the front frame; the bucket mechanism comprises a bucket and a bucket turning cover; the bucket is arranged at the front end of the movable arm; the bucket is provided with a feed inlet and a discharge opening; the bucket turning cover is rotatably arranged on the bucket, and is at the discharge opening; when materials are not discharged, the bucket turning cover fits the bucket, and the discharge opening of the bucket is closed; and the driving mechanism is connected with the bucket turning cover, and is used for driving the bucket turning cover to rotate. According to the working device of the self-discharge loading machine, traditional rocker arms and rocker arm cylinders are eliminated, and the structure is simplified; during discharge, the bucket turning cover directly rotates, discharge is quickened, and working efficiency is improved; and when the bucket turning cover is completely opened, discharge is more thorough.

Owner:GUANGXI UNIV

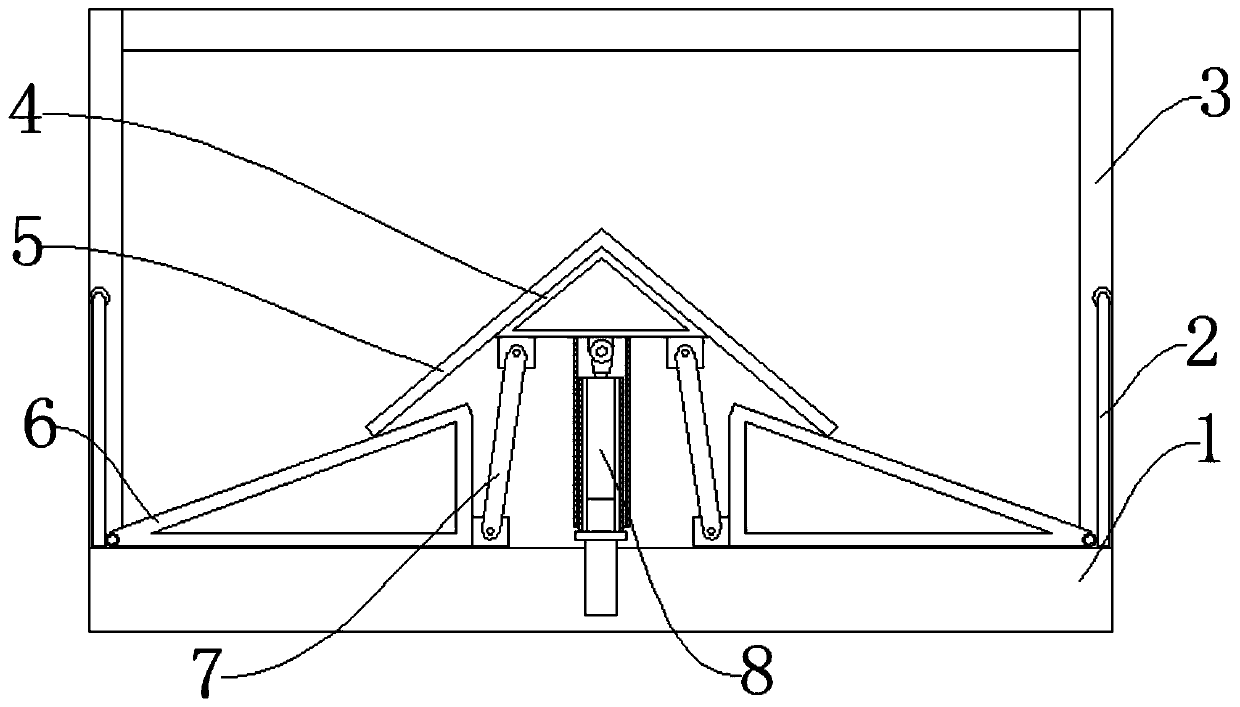

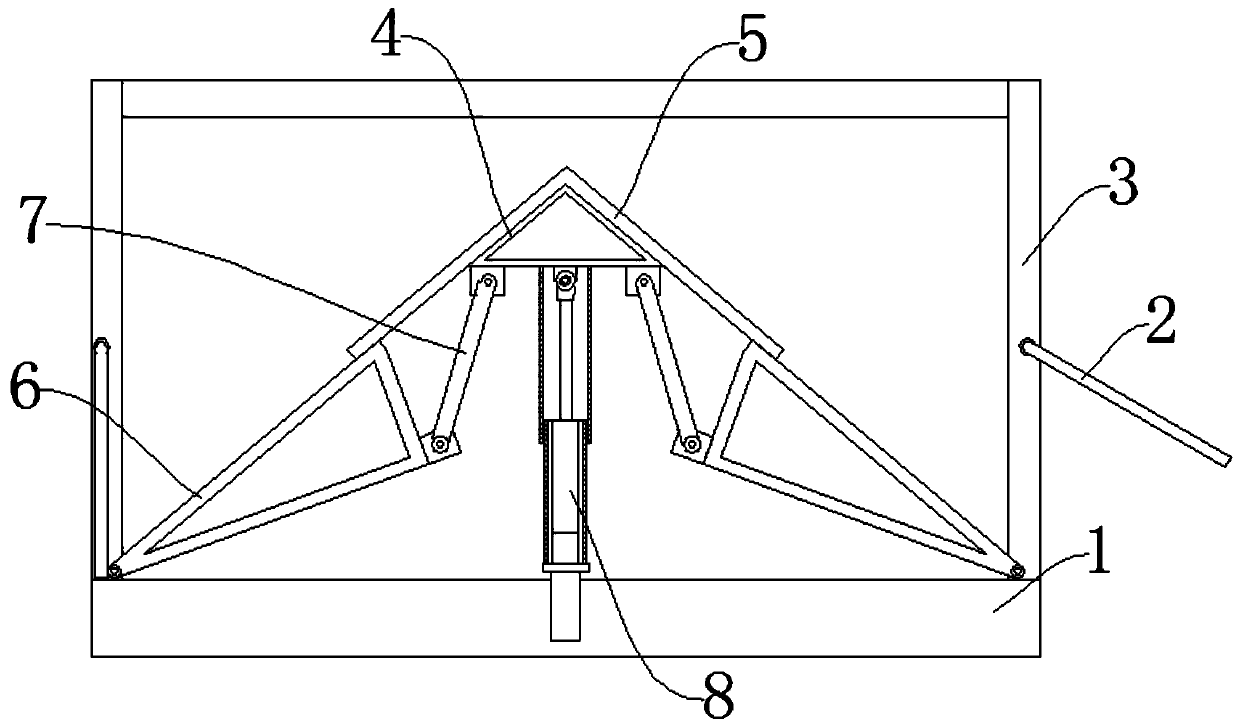

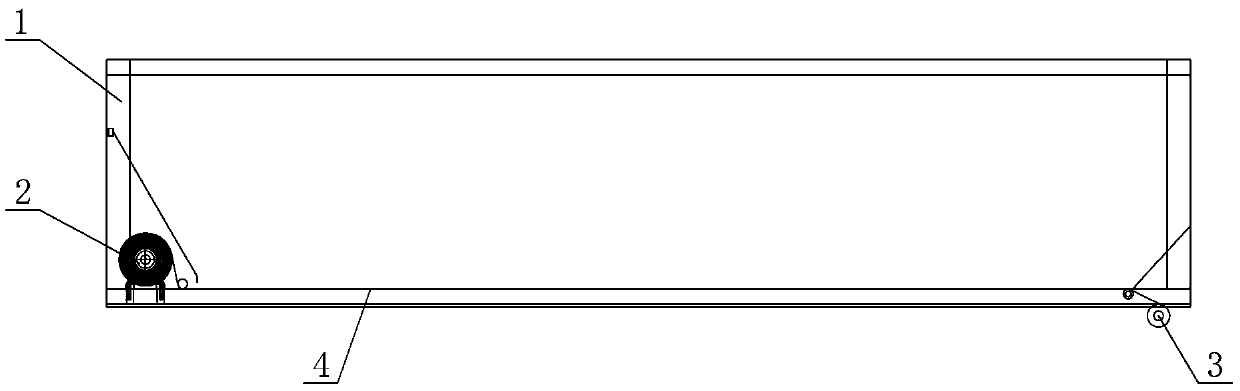

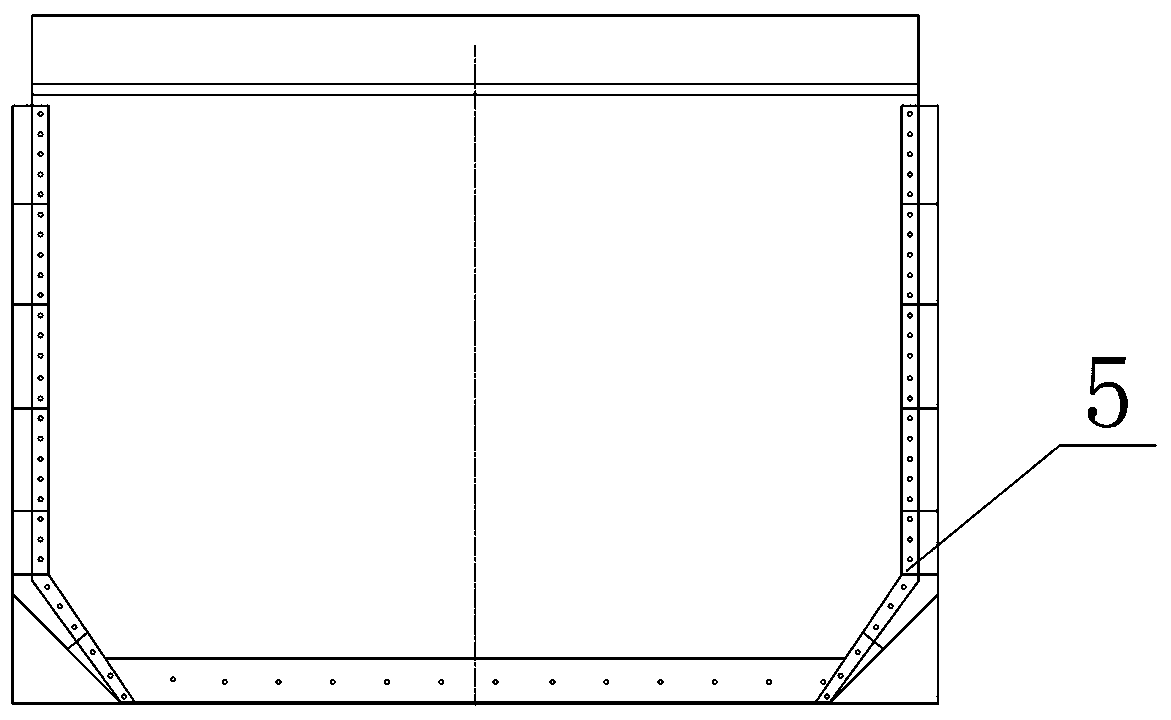

Bottom plate dual-rollover dumper

InactiveCN109866673AImprove stabilityAvoid uneven loadVehicle with tipping movementTransportation itemsRolloverHydraulic cylinder

The invention discloses a bottom plate dual-side-turning dumper. The dumper comprises a frame, a carriage, bottom triangular frames, hydraulic cylinders, a triangular plate and a top triangular frame.The carriage is arranged on the frame, a side door is hinged to the side wall of the carriage, the hydraulic cylinders are vertically mounted on the central axis in the front and back direction of the frame, the bottom triangular frames are symmetrically arranged on the two sides of the hydraulic cylinders, one corner of each bottom triangular frame extends to the side wall of the carriage and ishinged to the bottom of the side wall of the carriage, the triangular plate comprises two straight plates, the two straight plates are welded together along the edge, the lower portion of the triangular plate is fixedly connected with the top triangular frame, the lower surface of the top triangular frame is hinged to the piston ends of the hydraulic cylinders, and the top triangular frame is hinged to the bottom triangular frames on the two sides of the hydraulic cylinders through connecting rods. The dumper has the advantages of being high in safety, thorough in dumping, low in cost and thelike.

Owner:李彦明

Conveyer belt type self-discharging cargo compartment and dump truck composed of same

PendingCN110466411ATo achieve the purpose of unloadingUnload completelyVehicle with endless chains/beltsEngineeringTruck

Owner:LIANGSHAN TONGHUA SPECIAL PURPOSE VEHICLE

A centrifuge with adjustable discharge device

The invention provides a discharge device adjustable centrifugal machine which comprises a chassis, a rotating drum, an inner discharge device and an outer discharge device, wherein the rotating drum is rotationally mounted in the chassis and is driven to rotate by a first driving device; the inner discharge device comprises a second driving device, a driving rod, a connecting assembly and a cutter assembly; the driving rod stretches into the rotating drum from the upside; the second driving device drives the driving rod to move up and down; the outer discharge device comprises a vent pipe stretching into a part between the chassis and the rotating drum; a plurality of nozzles are formed on the vent pipe; the vent pipe is communicated with a blower; the nozzles face towards the rotating drum; the cutter assembly comprises a cutter rest, a cutter and a hair brush; and the cutter and the hair brush are respectively arranged on the two sides of the cutter rest. The discharge device adjustable centrifugal machine discharges more easily and cleanly, and the service life is increased.

Owner:湖南捷瑞化工有限公司

A mining electric locomotive transport body capable of quickly lifting and unloading ore

The invention relates to a mining electric locomotive, in particular to a mining electric locomotive transportation bucket capable of quickly hoisting and unloading ores. The technical problem to be solved by the invention is to provide the mining electric locomotive transportation bucket capable of quickly hoisting and unloading the ores; and the mining electric locomotive transportation bucket is fast in hoisting, loading and unloading speed, high in working efficiency and thorough in unloading in the unloading process. In order to solve the technical problem, the invention provides the mining electric locomotive transportation bucket capable of quickly hoisting and unloading the ores. The mining electric locomotive transportation bucket comprises a container bucket, wheels, a first baffle plate, a stop rod, a first support base, a first rotating shaft, a first rotating block, a second baffle plate, a first screw rod, a pressing plate, a first nut and the like; and the wheels are arranged on the left and right sides and the front and back sides of the lower side of the container bucket. The mining electric locomotive transportation bucket achieves the effects of acceleration of the loading speed, fast unloading speed, high working efficiency and thorough unloading in the unloading process.

Owner:FUJIAN MAKENG MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com