A centrifuge with adjustable discharge device

An unloading device and adjustable technology, applied in the field of centrifuges, can solve the problems of large chip resistance of wide scraper, uneven force on the tool, small chip resistance, etc., and achieve long service life, improve service life and high discharge efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

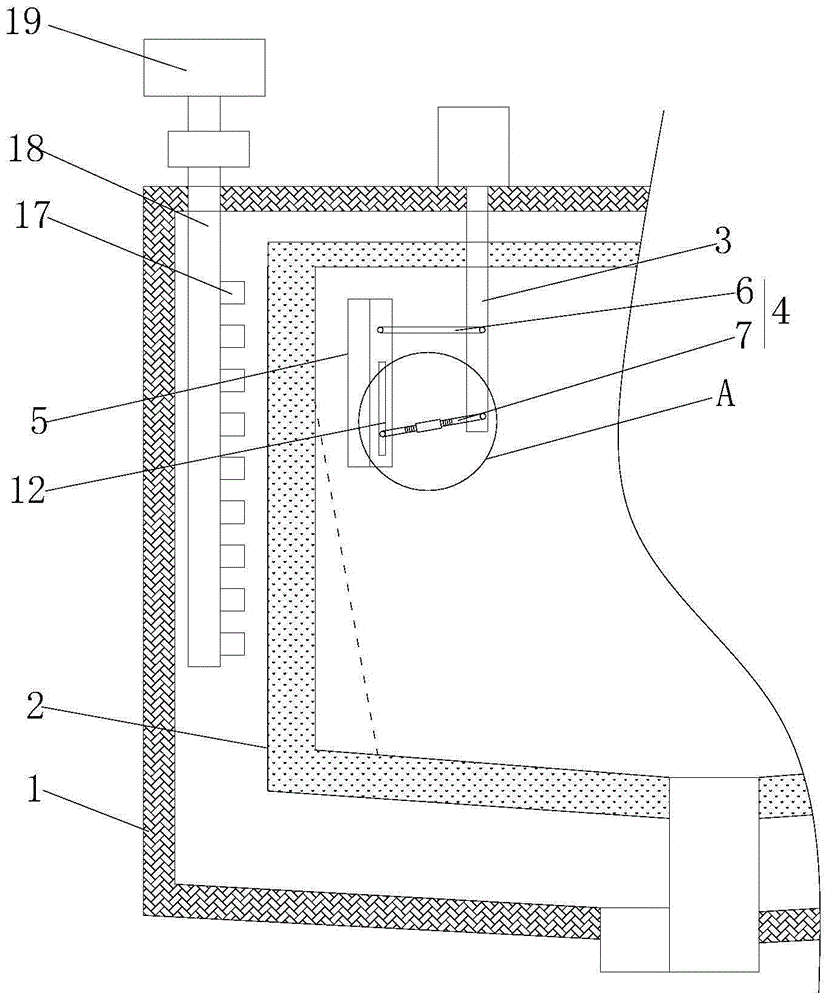

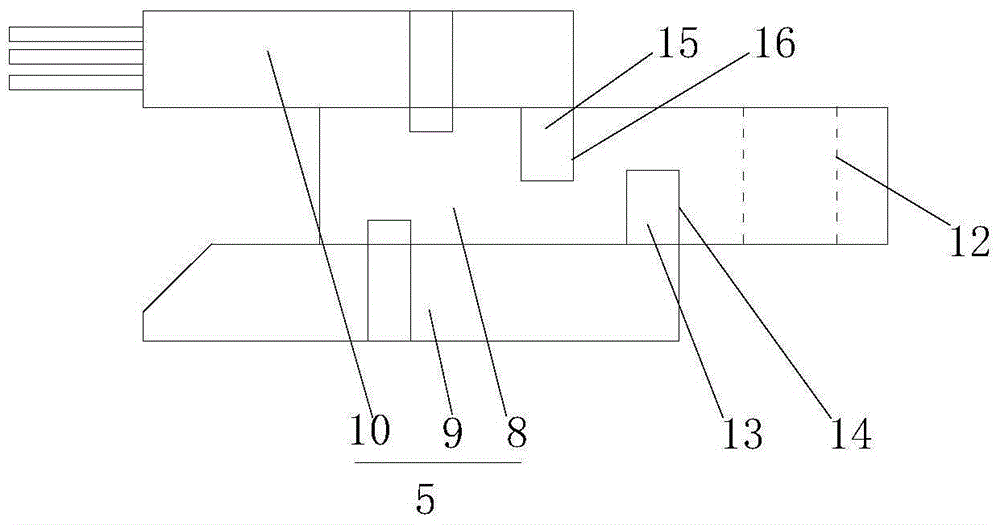

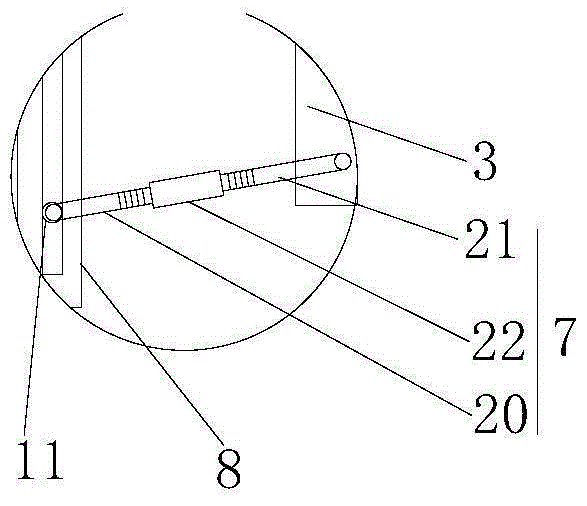

[0018] Such as figure 1 , figure 2 , image 3 as shown, figure 1 It is a structural schematic diagram of an adjustable centrifuge with an unloading device proposed by the present invention; figure 2 It is a structural schematic diagram of a scraper assembly in a centrifuge with an adjustable unloading device proposed by the present invention; image 3 It is an enlarged view of part A of a centrifuge with an adjustable unloading device proposed by the present invention.

[0019] refer to figure 1 , a centrifuge with an adjustable unloading device proposed by the present invention includes a casing 1, a drum 2, an inner unloading device and an outer unloading device, the drum 2 is rotatably installed in the casing 1, and the first The driving device drives the rotation;

[0020] The inner unloading device includes a second driving device, a driving rod 3, a connecting assembly 4 and a cutter assembly 5. The driving rod 3 extends into the drum 2 from above, and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com