Automatic flipping unloading system and its unloading method in garbage transfer station

A garbage transfer station and automatic flipping technology, which is applied in the direction of garbage storage, transportation and packaging, etc., can solve the problems of road and surrounding environmental pollution, hanging garbage, etc., to avoid manual cleaning, high unloading efficiency, and clean unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

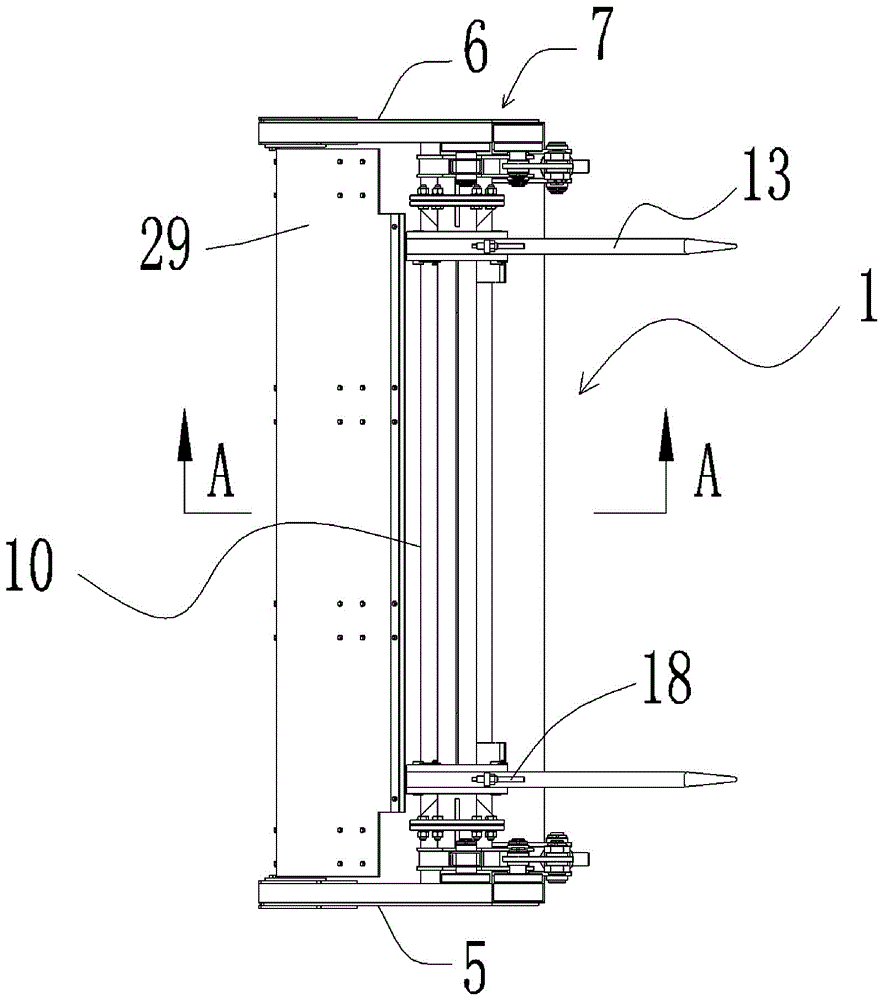

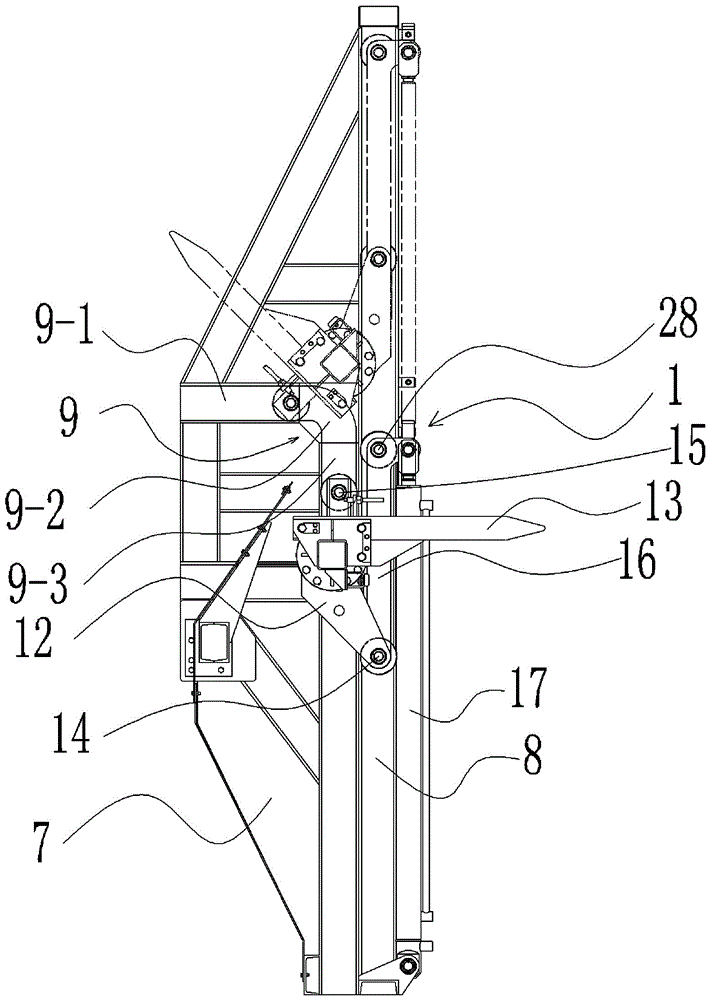

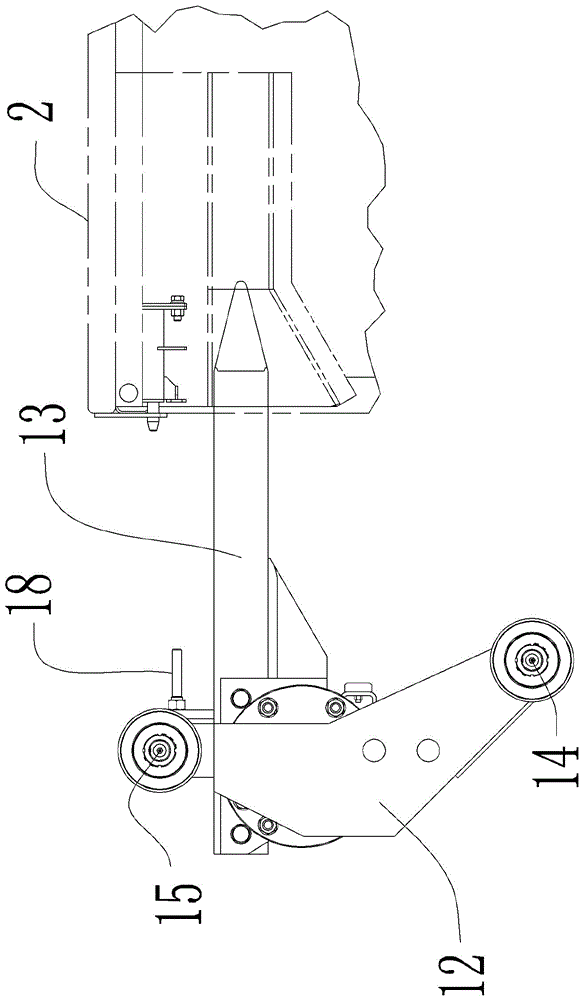

[0045] see Figure 1 to Figure 10 , is a specific embodiment of the automatic turning and unloading system of the garbage transfer station. The automatic turning and unloading system of the garbage transfer station includes a turning and unloading device 1, a garbage collection box 2 with an upward-opening discharge door, and a garbage transport vehicle 3 for transporting the garbage collection box 2 with an upward-opening discharge door.

[0046] The turning and unloading device 1 is fixedly installed at the notch of the feeding trough 4 of the garbage transfer station. The turning and unloading device 1 includes a base frame 7 composed of a left chute frame 5 and a right chute frame 6, which are symmetrically arranged. In the embodiment, the left chute frame and the right chute frame are all welded by channel steel to form a vertical frame structure. In order to strengthen the structural strength of the base frame, the bottom and middle part Connected by connecting channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com