Rapid material unloading and storing barrel of plastic powder agitator

A mixer and storage tank technology, which is applied in the field of fast unloading storage tanks, can solve the problems of unclean unloading, plastic powder residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

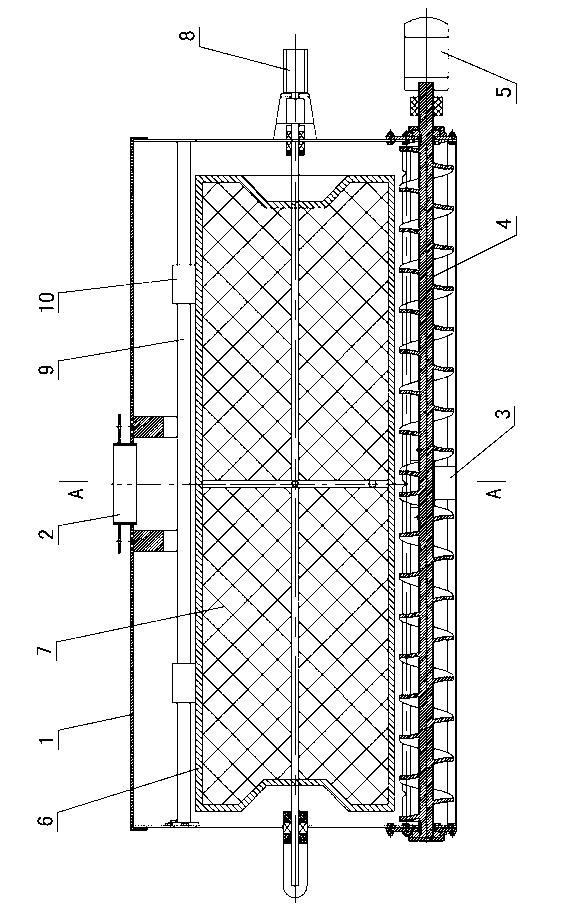

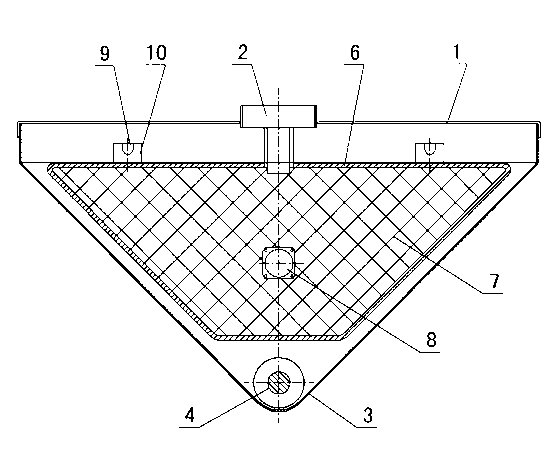

[0009] The invention relates to a fast discharge storage tank for a plastic powder mixer, such as figure 1 , figure 2 As shown, the cylinder body 1 including the storage tank of the mixer, the cross section of the cylinder body 1 is an inverted triangle, the cylinder body 1 is formed with a feed port 2 and a discharge port 3, and the cylinder body 1 is provided with a discharge auger 4. The unloading auger 4 is driven by the unloading motor 5. It is characterized in that a net frame 6 is arranged inside the cylinder body 1. The shape of the net frame 6 corresponds to the cylinder body 1. There is an inclined net 7 installed on the net frame. Frame 6 is driven to move left and right by pushing cylinder 8, and the movement of network frame 6 has guiding mechanism. In this scheme, a network frame 6 is set in the cylinder body 1. The shape of the network frame 6 corresponds to the cylinder body 1. The network frame 6 is equipped with an inclined net 7. The network frame 6 is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com