A kind of aluminum sol production method

A production method and technology of aluminum sol, applied in sol preparation, chemical instruments and methods, aluminum halide, etc., can solve the problems of complex operating conditions, potential safety hazards, easy overpressure and overtemperature, and high energy consumption, and achieve stable and safe operation process. Avoid the effects of rapid heating of the reaction and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

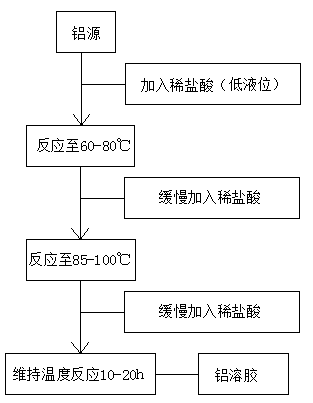

Method used

Image

Examples

Embodiment 1

[0021] The volume of the reactor is 25m³, the volume of the silo is 3m³, 1.5 tons of aluminum scraps are fed into the single kettle, 16.8 tons of 8wt% hydrochloric acid, and the output of the single kettle is 13 tons. Add 1 / 4 first, and after 30 minutes, the temperature will rise to 75°C, and the temperature will not continue to rise, and white water vapor will overflow from the vent. After maintaining the temperature for 20 minutes, continue to add dilute hydrochloric acid to the reactor, observe the temperature change during the dosing process, and adjust the feeding speed. After the temperature rises to 90°C, add a small amount of dilute hydrochloric acid to maintain the temperature for reaction , A small amount of overflow liquid flows from the reactor overflow port into the circulation storage tank, through the overflow port, it can prevent the tank from leaking. After the hydrochloric acid is added, slowly add the feed liquid from the circulation storage tank to the react...

Embodiment 2

[0023] The volume of the reactor is 35m³, the volume of the silo is 5m³, 3 tons of aluminum chips are fed into the single kettle, 25.6 tons of 10wt% hydrochloric acid, and the output of the single kettle is 15 tons. Add 1 / 3 first, and after 20 minutes, the temperature will rise to 80°C, and the temperature will not continue to rise, and white water vapor will overflow from the vent. After maintaining the temperature for 15 minutes, continue to add dilute hydrochloric acid to the reactor, observe the temperature change during the dosing process, and adjust the feeding speed. After the temperature rises to 100°C, add a small amount of dilute hydrochloric acid to maintain the temperature for reaction , A small amount of overflow liquid flows from the reactor overflow port into the circulation storage tank, through the overflow port, it can prevent the tank from leaking. After the hydrochloric acid is added, slowly add the feed liquid from the circulation storage tank to the reacto...

Embodiment 3

[0025] The volume of the reactor is 30m³, the volume of the silo is 3m³, 2 tons of aluminum chips are fed into the single kettle, 20.5 tons of 9wt% hydrochloric acid, and the output of the single kettle is 14.5 tons. Add 1 / 6, and after 35 minutes, the temperature rises to 70°C. After the temperature does not continue to rise, white water vapor will overflow from the vent. After maintaining the temperature for 30 minutes, continue to add dilute hydrochloric acid to the reaction kettle. During the dosing process, pay attention to observe the temperature change and adjust the feeding speed. After the temperature rises to 97°C, add a small amount of dilute hydrochloric acid to maintain the temperature for reaction , A small amount of overflow liquid flows from the reactor overflow port into the circulation storage tank, through the overflow port, it can prevent the tank from leaking. After the hydrochloric acid is added, slowly add the feed liquid from the circulation storage tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com