On-line detection device for water content of machine-made sand

A detection device, machine-made sand technology, applied to measuring devices, by removing certain components, weighing, instruments, etc., can solve problems such as complex operations, shortage of natural river sand, and inability to fully meet construction projects, and achieve accurate calculation results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

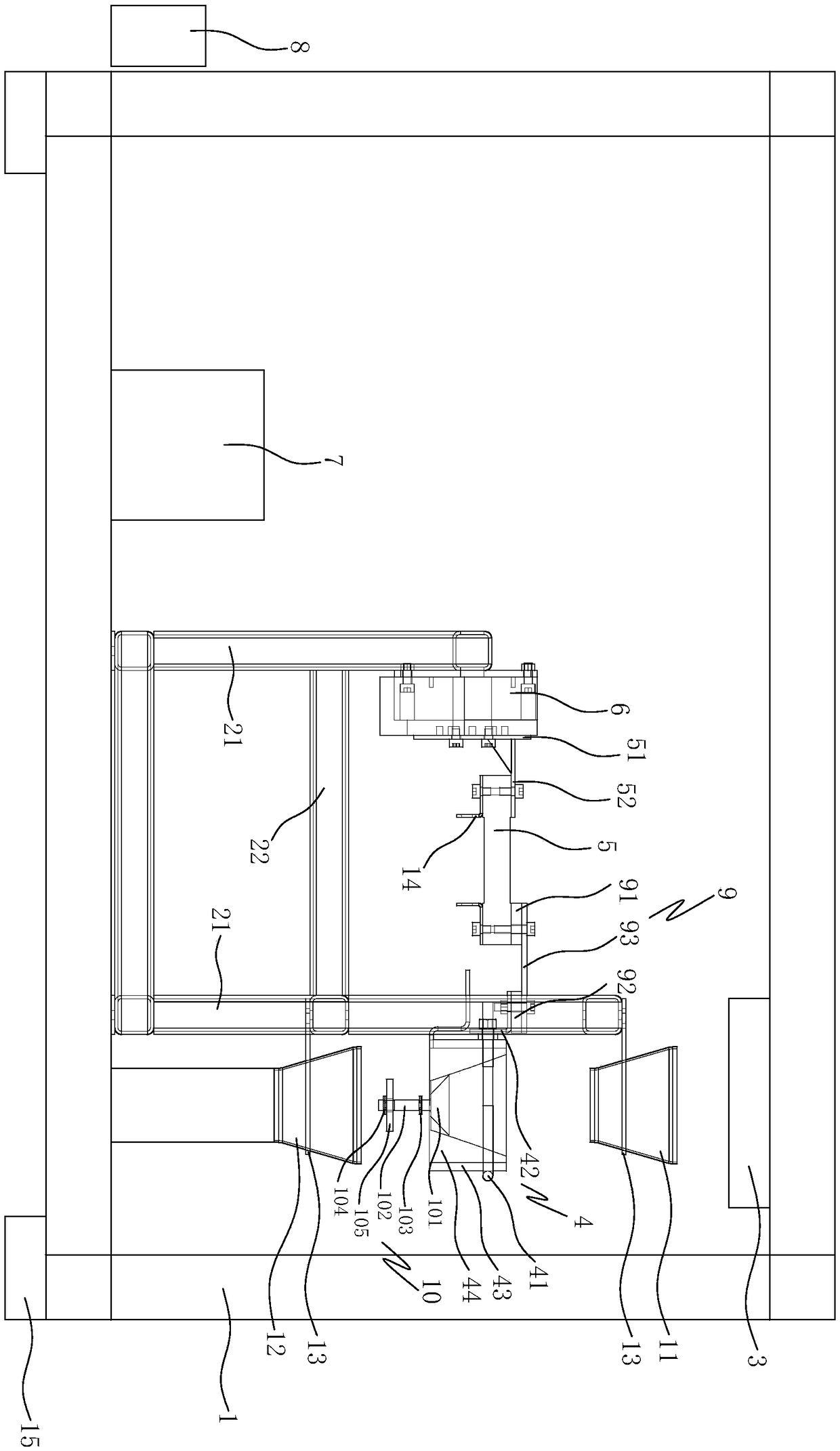

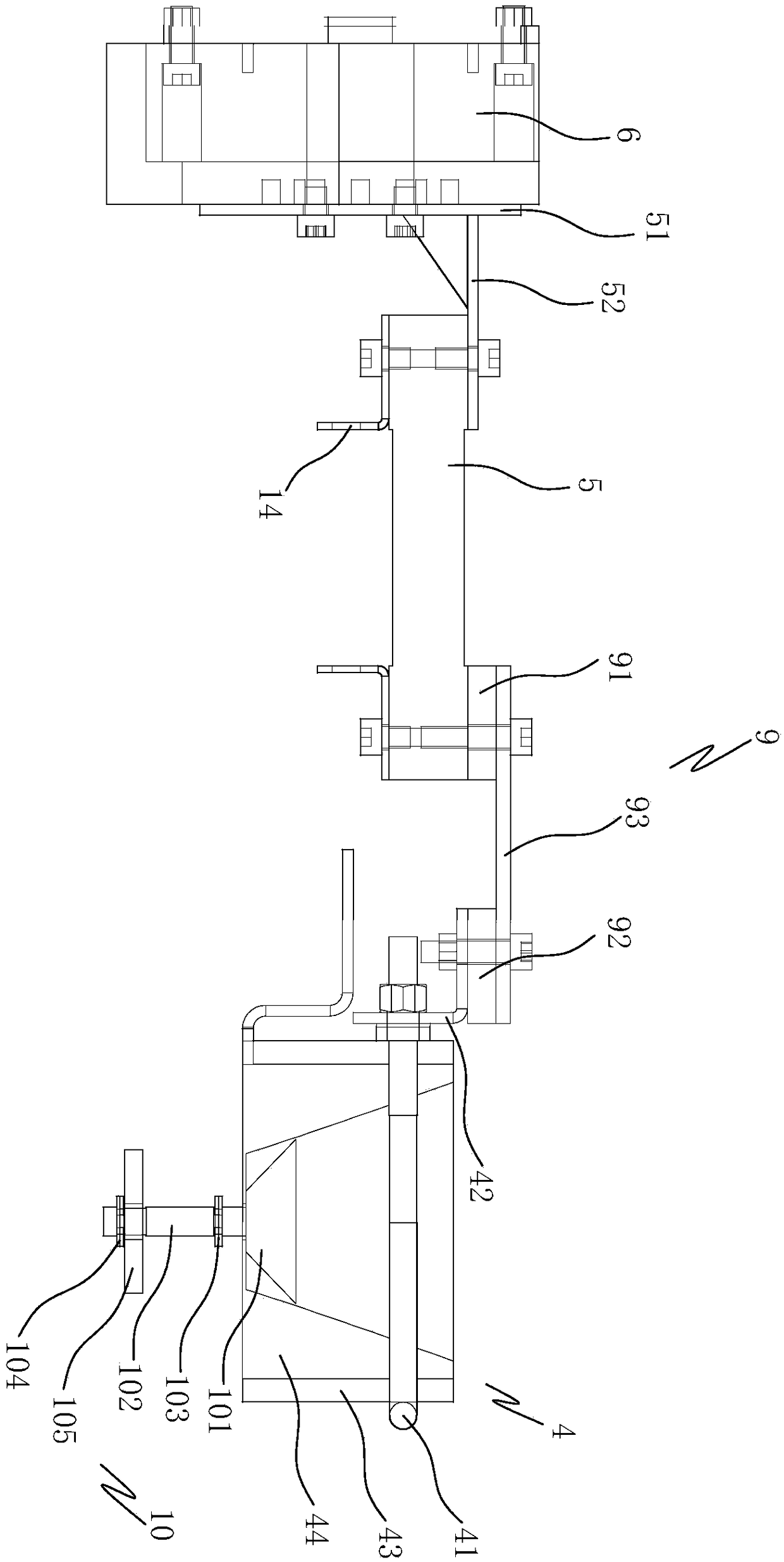

[0027] Such as figure 1 and figure 2 As shown, the online detection device for the moisture content of machine-made sand includes a casing 1, a bracket, a sampling device 3, a drying device 4, a weighing device 5, a turning device 6, a control device 7, a human-computer interaction device 8, a heat insulation device 9, an anti- The blocking device 10, the feed pipe 11, the discharge pipe 12, the wire fixing plate 14 and the shock absorbing pad 15, the human-computer interaction device 8 is arranged outside the shell 1, the sampling device 3 is set inside the top of the shell 1, and the control device 7 is set Inside the bottom of the shell 1, the bracket includes two vertical bars 21 arranged at intervals inside the bottom of the shell 1 and a cross bar 22 arranged between the two vertical bars 21, the shock absorbing pad 15 is set on the outside of the bottom of the shell 1, and the rest of the components are arranged on the bottom of the shell 1. Inside shell 1. The contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com