Full-automatic bag breaking feeding system

A fully automatic, bag-breaking technology, applied in the stacking of objects, de-stacking of objects, loading/unloading, etc., can solve the problems of unfavorable flow of broken bags, increased labor costs, and low degree of automation. The recycling method is simple and fast, the labor cost is reduced, and the degree of automation is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

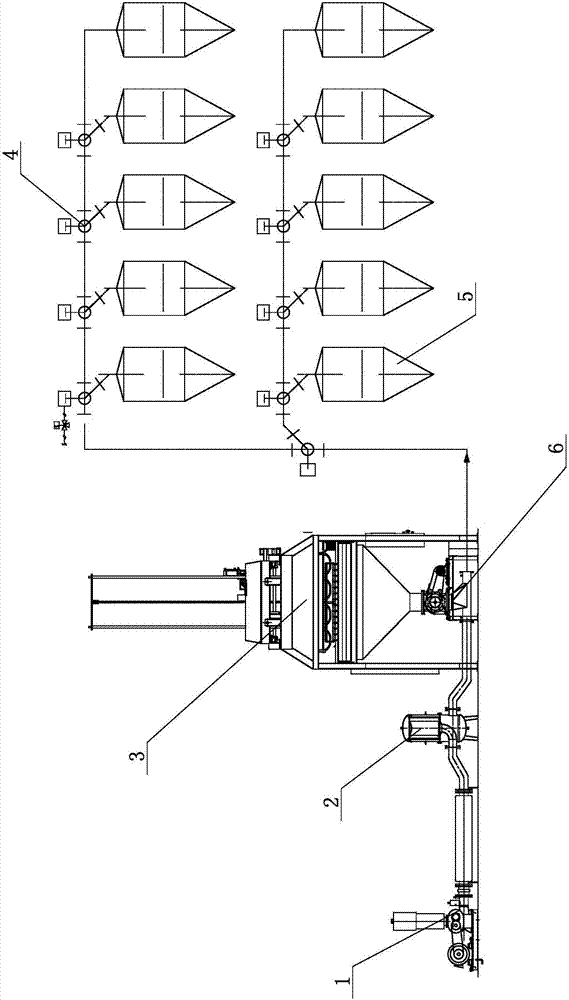

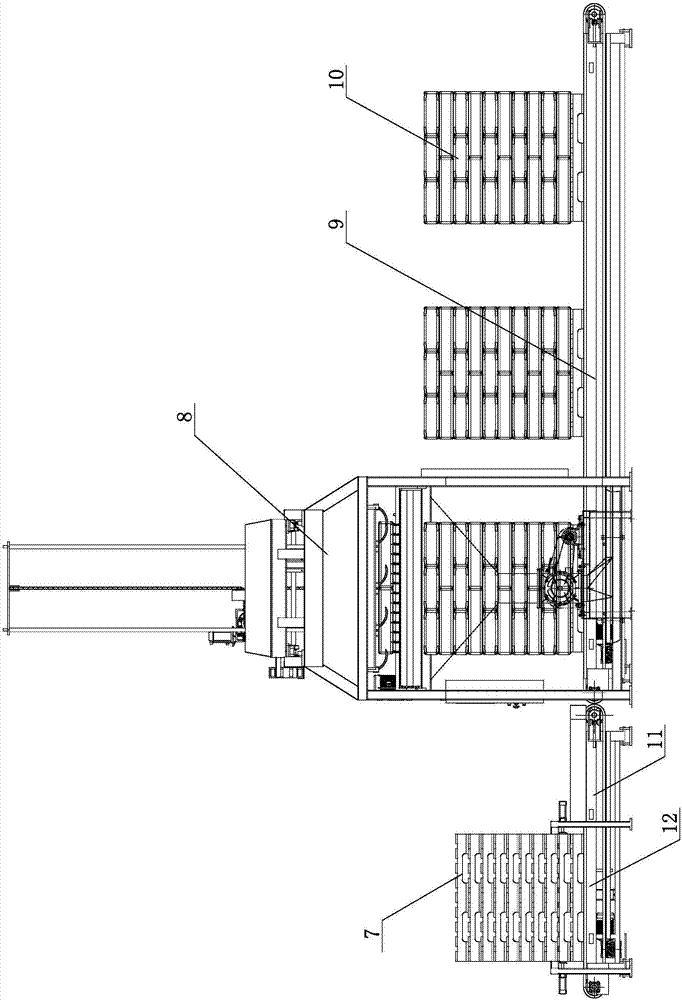

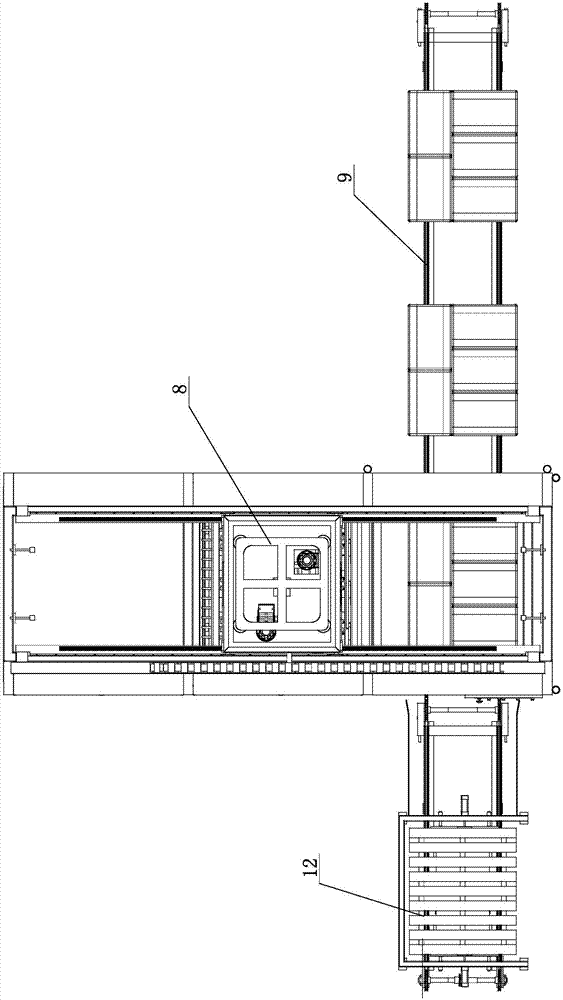

[0048] Such as figure 1 As shown, the automatic bag-breaking feeding system of the present invention includes a bag-breaking unloading machine 8 and an air supply device 1, the lower end of the bag-breaking unloading machine 8 is connected to a star-shaped discharge machine 6, and the star-shaped discharge machine The discharge port of 6 is connected with the material conveying pipeline, and the left end of the material conveying pipeline is connected with the air supply device 1. The air supply device 1 adopts a screw compressor, and the screw compressor is connected with the material conveying pipeline through the air supply pipeline. The air filter 2 is set, and the right end of the feeding pipeline is externally connected with multiple sets of feed bins 5; the top of the feed bin 5 is provided with a shunt valve 4, and the shunt valve 4 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com