Conveyer belt type self-discharging cargo compartment and dump truck composed of same

A technology for conveyor belts and dump trucks, applied in the direction of vehicles with endless chains/ring belts, etc., can solve the problems of high manufacturing cost, increased weight of dump trucks, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

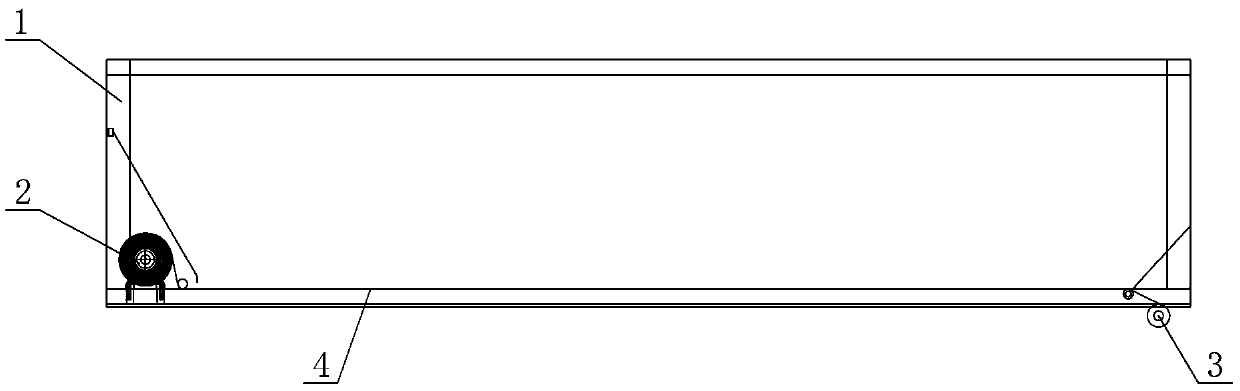

[0023] Such as figure 1 As shown, the structure diagram of the first embodiment of the conveyor belt type self-unloading cargo compartment of the present invention is given, which is composed of a compartment 1, a front belt shaft 2, a rear belt shaft 3 and a transmission belt 4, and the compartment 1 is used to store goods Or material, front belt shaft 2 and rear belt shaft 3 rotate respectively the front end and the rear end that are arranged on compartment 1, front belt shaft 2, rear belt shaft 3 are all connected with the power unit that drives it to rotate, and power unit can adopt hydraulic motor. The conveyor belt 4 is located at the bottom of the compartment 1, so that the materials in the compartment 1 can be taken out during the right front and rearward movement of the conveyor belt 4. The front end of the transmission belt 4 is fixed and wou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com