Bottom plate dual-rollover dumper

A dump truck and rollover technology is applied in the arrangement of loading and unloading vehicles, motor vehicles, and vehicles used for freight transportation. , The effect of clean discharge and uniform load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

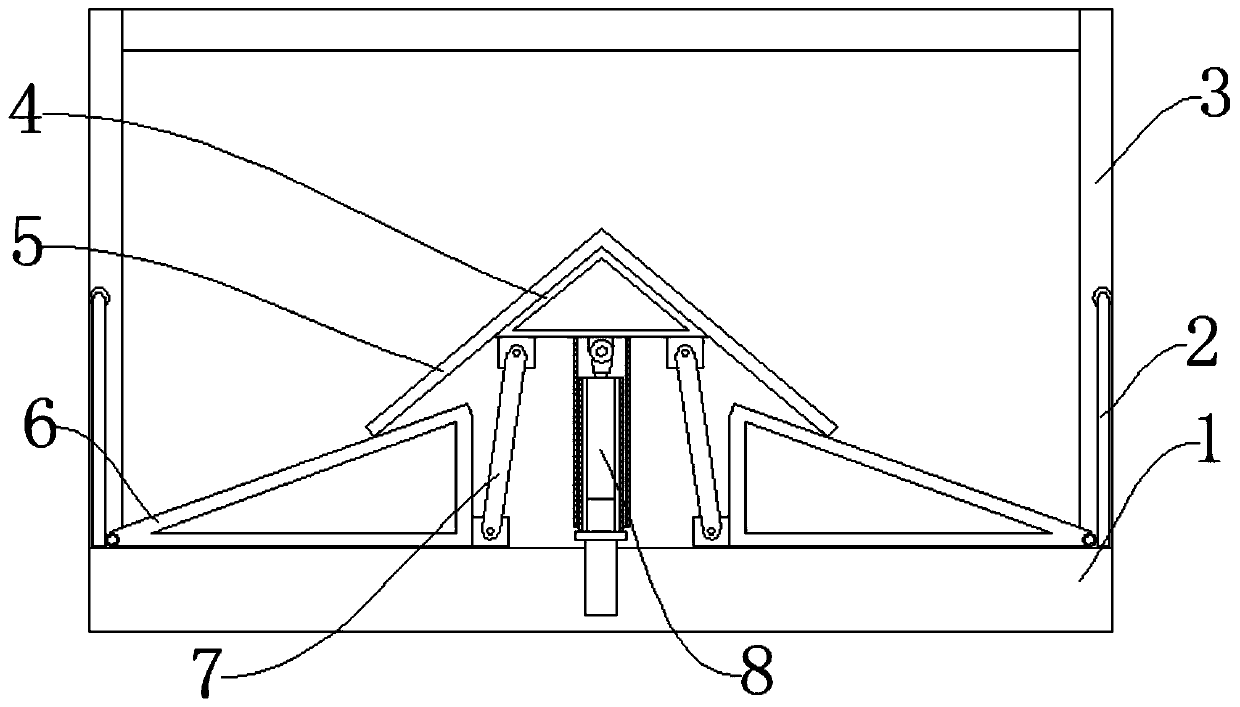

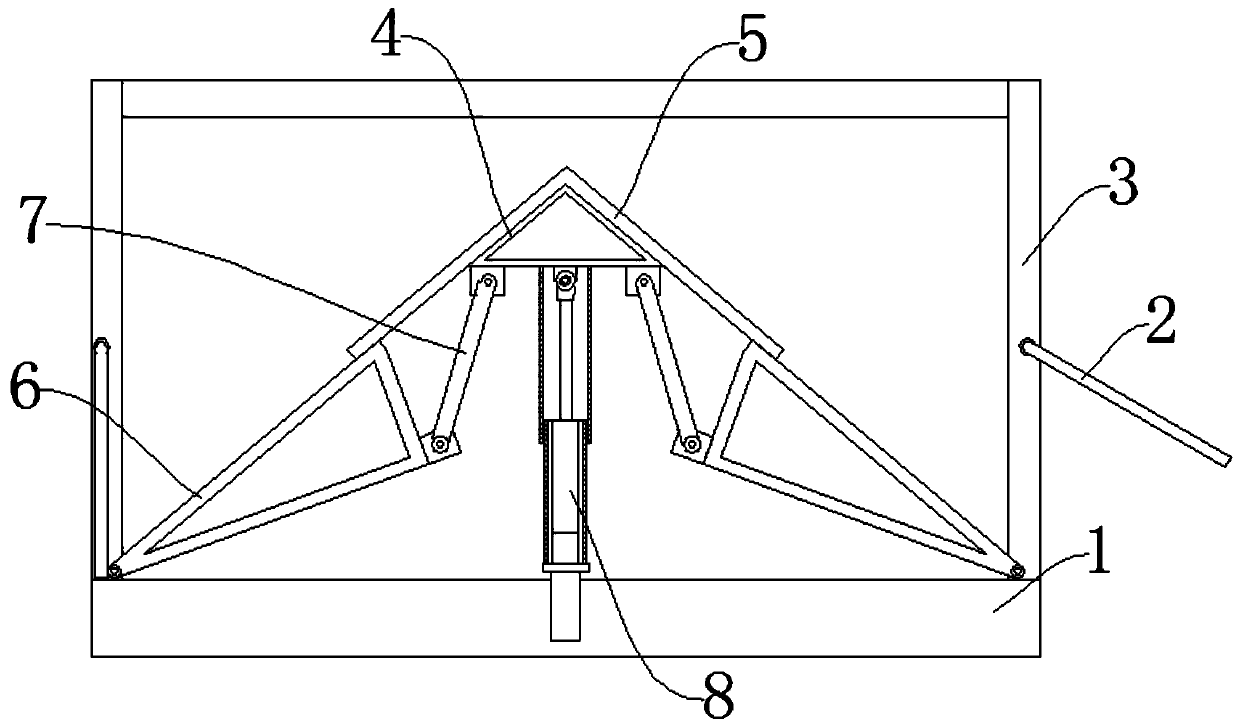

[0029] Such as Figure 1-Figure 2 As shown, a dump truck with a double-sided bottom plate includes a vehicle frame 1, a compartment 3, a bottom tripod 6, a hydraulic cylinder 8, a triangular plate 5 and a top tripod 4, the compartment 3 is installed on the frame 1, and the compartment 3 has two Side door 2 is hinged on the side wall of side, and hydraulic cylinder 8 is vertically installed on the central axis of vehicle frame 1 front and rear direction, and hydraulic cylinder 8 quantity is 3, and the central axis of vehicle frame 1 front and rear direction is evenly arranged, and hydraulic cylinder 8 The jacking force is 20 tons. In this embodiment, for a dump truck with a load capacity of 35 tons, three hydraulic cylinders 8 with a jacking force of 20 tons can ensure the safety of lifting. The bottom tripod 6 is symmetrically arranged on the left and right sides of the hydraulic cylinder 8, and one corner of the bottom tripod 6 extends to the side wall of the compartment 3 an...

Embodiment 2

[0035] Embodiment 2 is improved on the basis of Embodiment 1. In this embodiment, the angle between the upper surface of the bottom tripod 6 and the horizontal plane is 10°. In this embodiment, because the height of the bottom tripod 6 is lower, the occupied Compartment 3 has less volume, more goods are transported under compartment 3 of the same size, and the economy is better, but the cargo unloading capacity is not as good as that of embodiment 1 under normal conditions.

[0036] The rest of the structure and working principle of embodiment 2 are the same as embodiment 1.

Embodiment 3

[0038] Embodiment 3 is improved on the basis of Embodiment 1. In this embodiment, the angle between the upper surface of the bottom tripod 6 and the horizontal plane is 25°. In this embodiment, because the height of the bottom tripod 6 is higher, the Under normal conditions, the inclination of the goods is higher, and most of the goods can be unloaded by relying on the self-weight of the goods under normal conditions. Unloading is more convenient, but it occupies a larger compartment 3.

[0039] The rest of the structure and working principle of embodiment 3 are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com