Novel method for unloading and delivering liquid ammonia

A new method, liquid ammonia technology, applied in container filling method, gas/liquid distribution and storage, equipment loaded into pressure vessels, etc., can solve the problem of large nitrogen consumption, achieve the effect of complete unloading and avoid potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited.

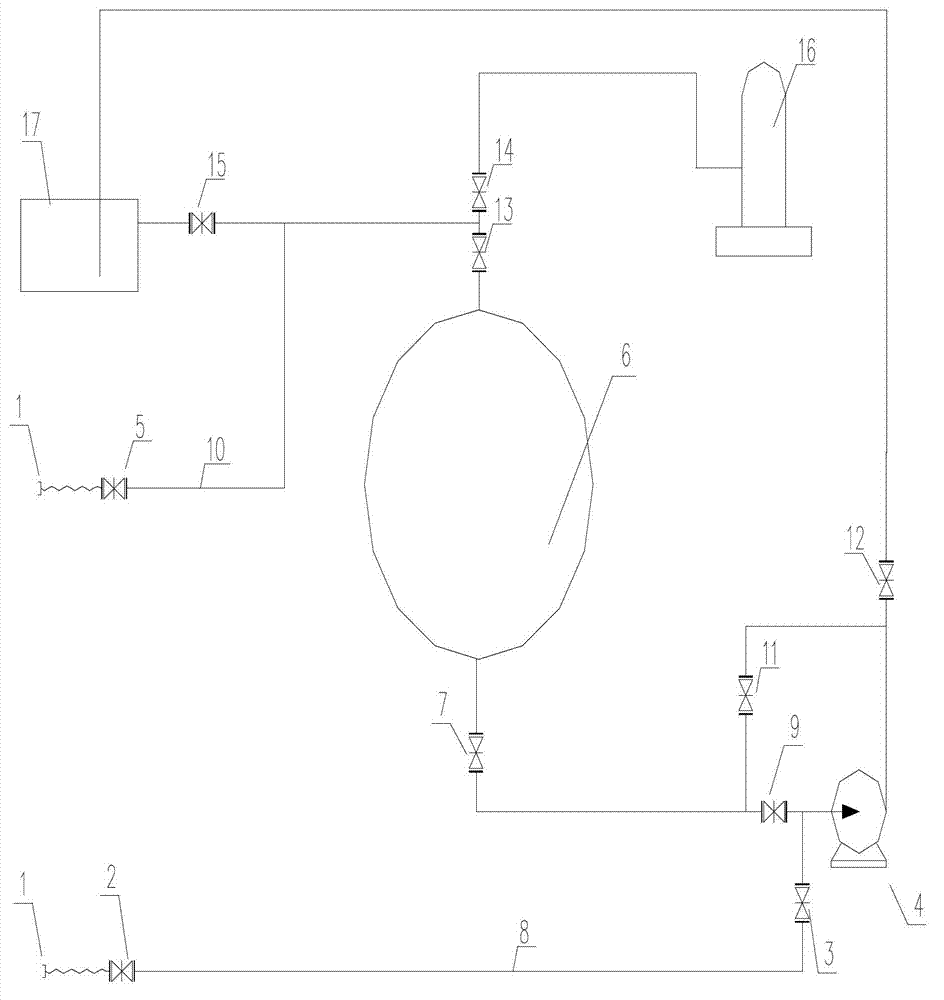

[0019] Liquid ammonia unloading condition: first connect the tank car connection joint 1 on the unloading pump inlet pipeline 8 and the unloading gas-phase communication pipeline 10 to the liquid ammonia tank car, open the front unloading pump inlet valve 2, the rear unloading pump inlet valve 3, unloading control Valve 11, storage tank liquid phase outlet cut-off valve 7, front gas phase communication valve 13 and unloading gas phase communication valve 5, and other valves remain closed. The liquid ammonia is transported from the tank truck to the liquid ammonia storage tank 6 through the liquid ammonia delivery pump 4 . Since the gas phase space of the liquid ammonia storage tank is connected with the gas phase space of the tank truck, the liquid ammonia delivery pump only needs to overcome the potential difference and pipeline resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com