A mine transport vehicle

A technology for transport vehicles and mines, which is applied in the direction of transporting passenger vehicles, mining vehicles, transportation and packaging, etc., and can solve problems such as inability to load heavy minerals, inconvenient loading and unloading, and insufficient structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

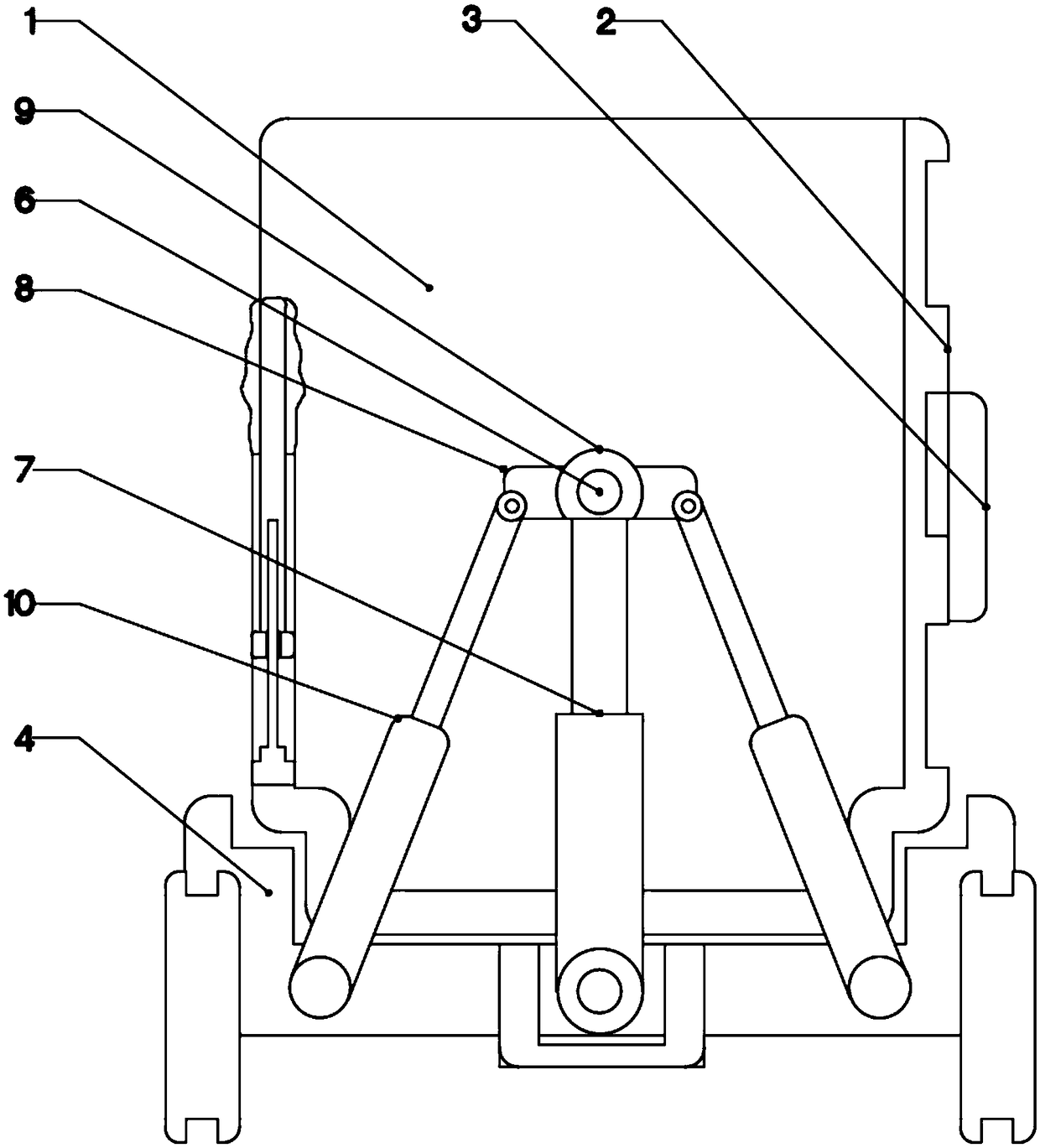

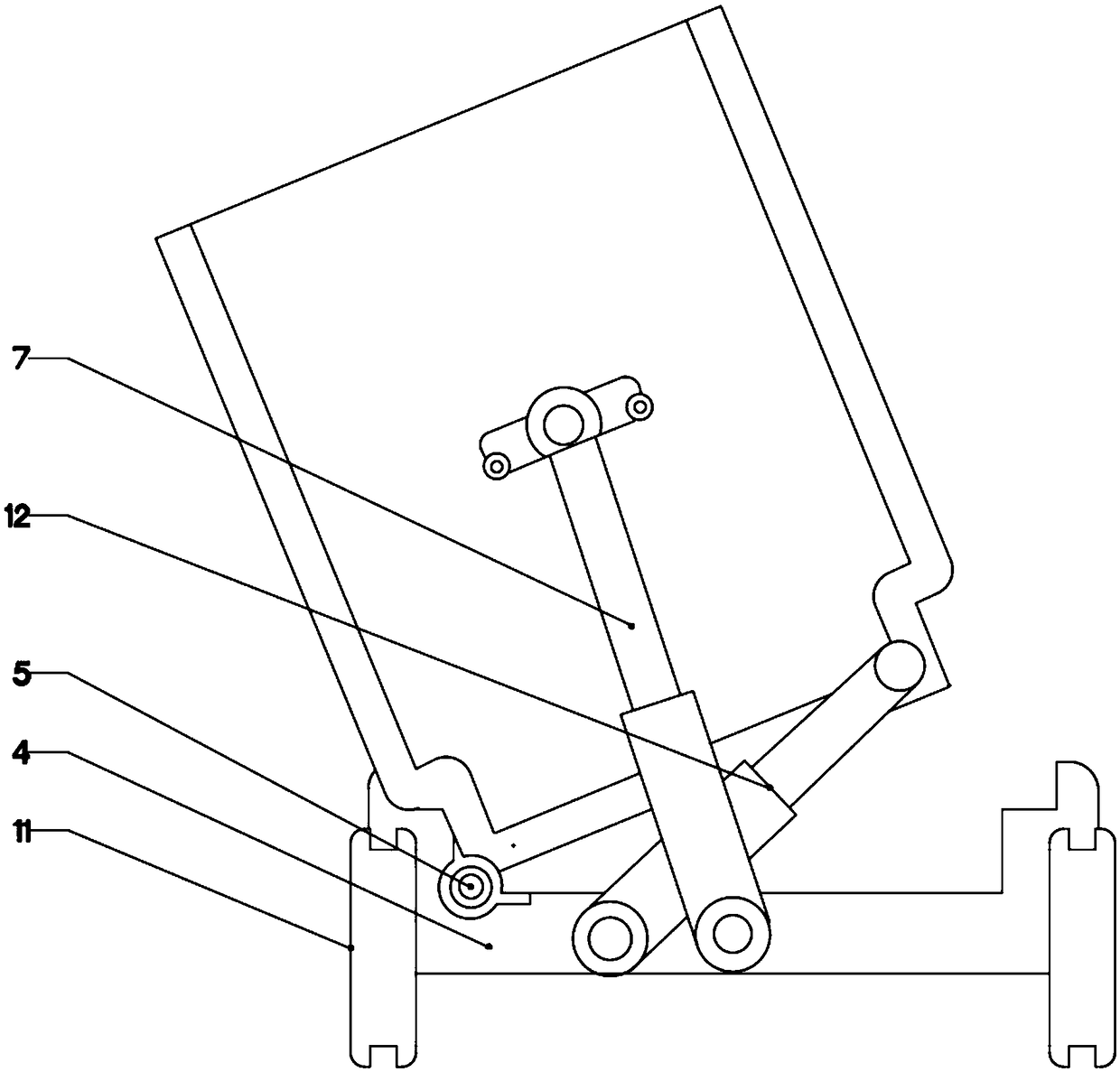

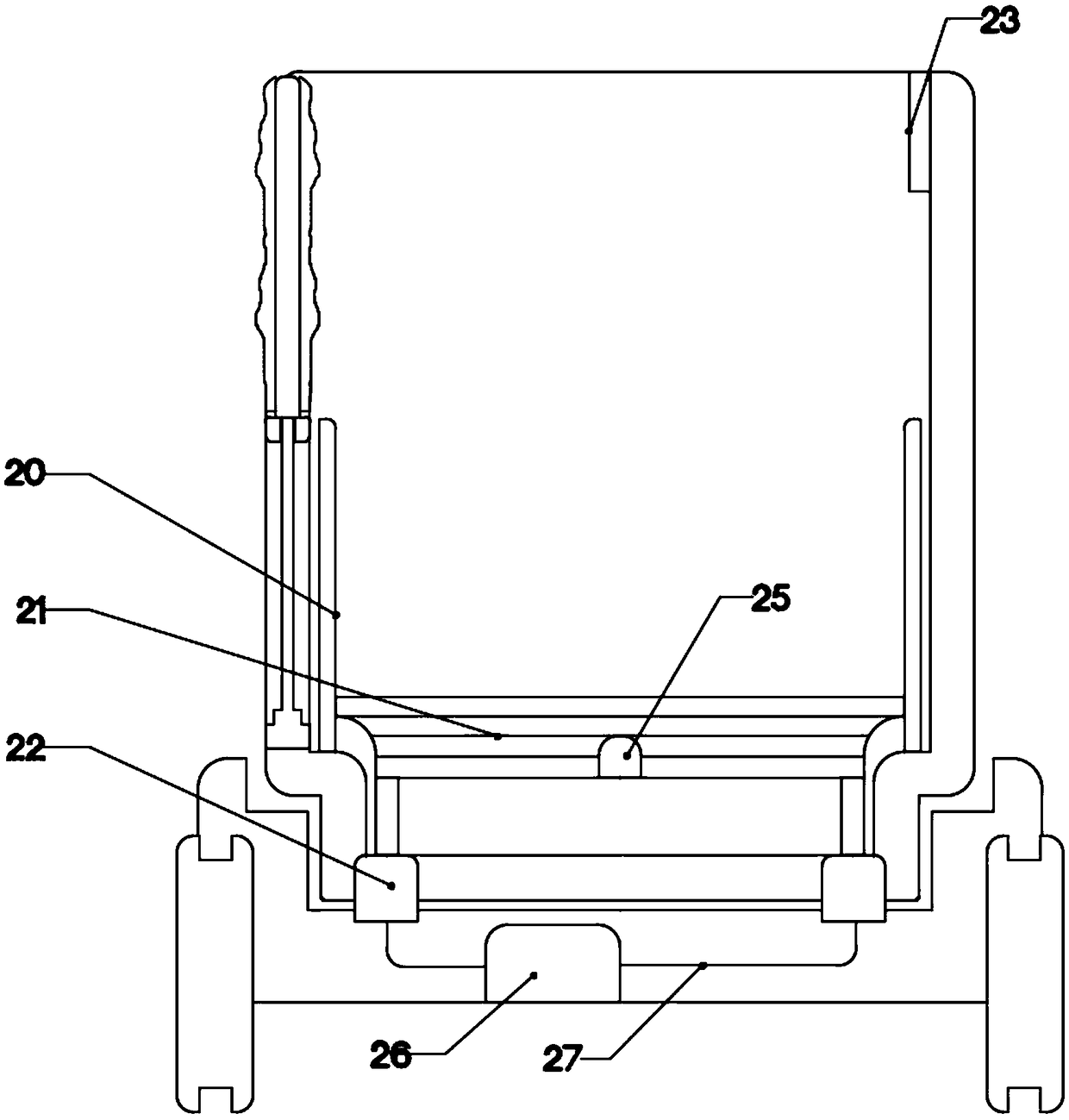

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 shown.

[0022] In this embodiment, the function of the supporting device can make the mine transport vehicle have a more stable center of gravity when unloading, so that the installation box one 8 always bears the center of gravity of the rectangular carriage 1 . The height of the baffle plate of the transport vehicle can be changed through the action of the fence device, so that the minerals can be unloaded more easily, and the minerals at the bottom of the rectangular compartment 1 can be unloaded more thoroughly through the action of the pushing device.

[0023] In the first step, when unloading is required, the controller 3 controls the oil pump 26 to start working. The oil pump is independently controlled by the hydraulic cylinder 1 7, hydraulic cylinder 2 12, and hydraulic cylinder 3 22. The controller 3 first controls the fence device to work , the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com