Traction-type residual film recovery compression and straw returning combined operation machine

A combined operation machine and residual film recycling technology, which is applied to harvesters, collectors, crop processors, etc., can solve the problems of poor applicability of residual film recovery, increase the burden and cost of farmers, and affect the working efficiency of machines and tools. Improve operating efficiency, increase loading capacity, and facilitate film unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

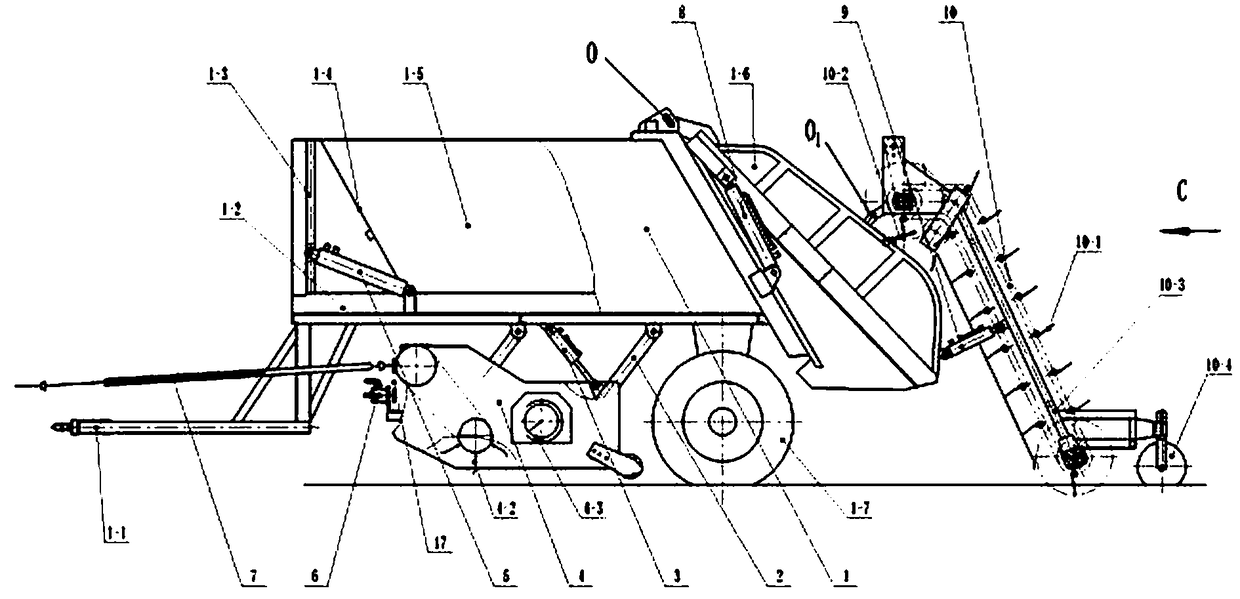

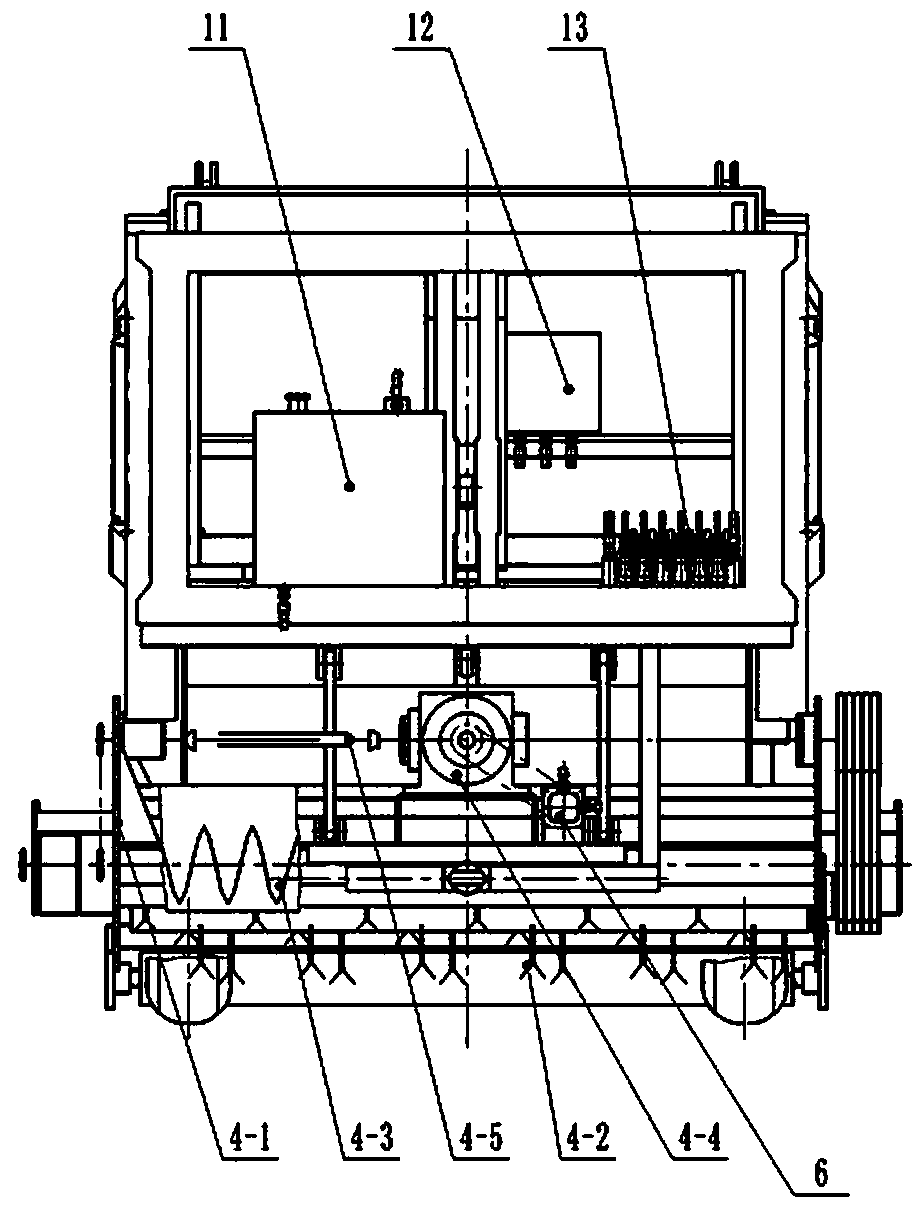

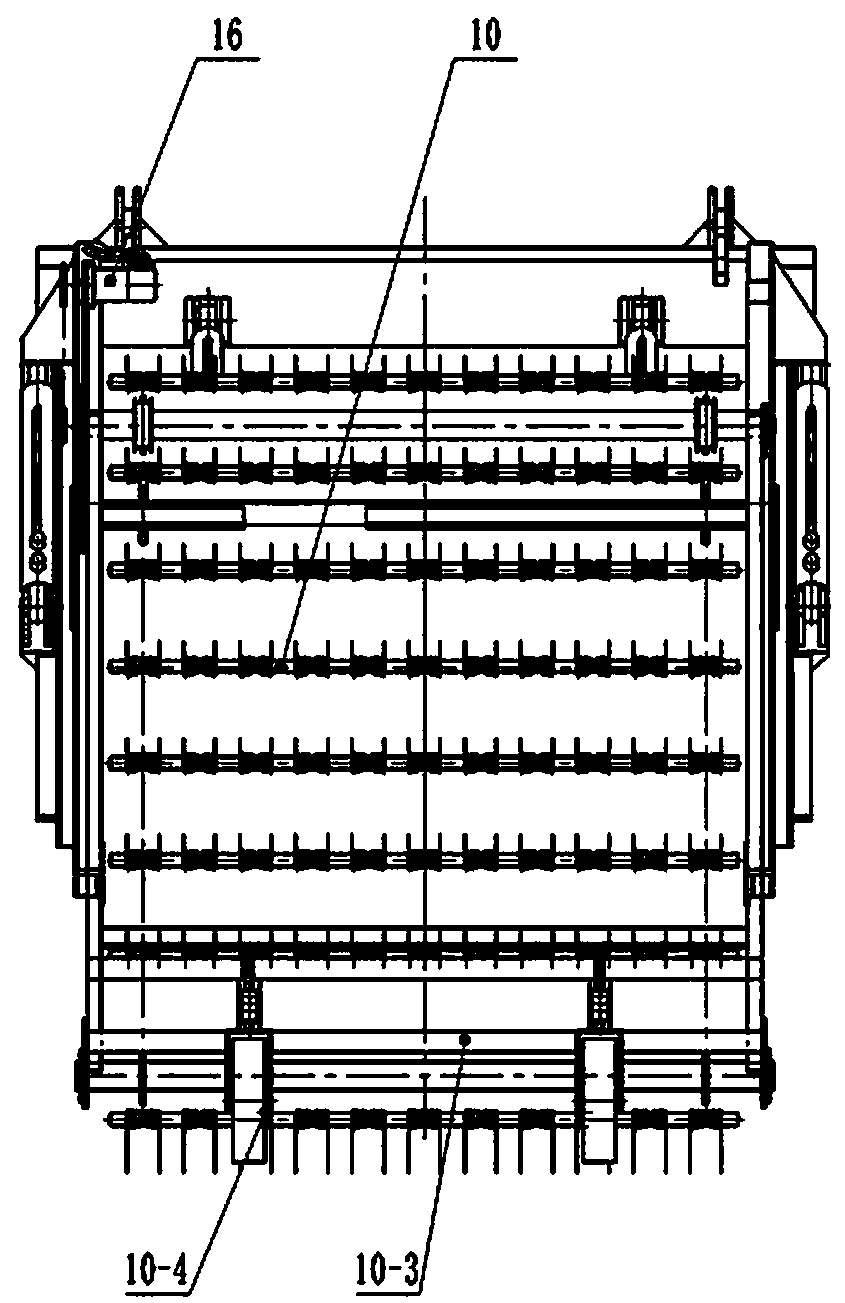

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the embodiment of the present invention discloses a traction-type residual film recovery compression and straw returning combined operation machine, including a universal joint transmission shaft 7, an electric control system, a hydraulic system, a residual film collection and compression part 1, a straw The crushing and returning part 4 and the residual film recycling part 10, the straw crushing and returning part 4 is located at the front and lower part of the residual film collection and compression part 1, and the residual film recycling part 10 is located at the bottom of the residual film collection and compression part 1 Rear; the electric control system includes a distribution box and lines, and the hydraulic system includes a fuel tank 11, a hydraulic pump 6, a hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com