Material mixing equipment at milk powder dry mixing section and material mixing method

A mixing equipment and dry mixing technology, applied in mixing methods, chemical instruments and methods, mixers with rotary stirring devices, etc., can solve the problem of uneven mixing, uneven nutrition, and rough dry mixing of dairy powder. problems, to achieve the effect of high mixing quality uniformity, less residue, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

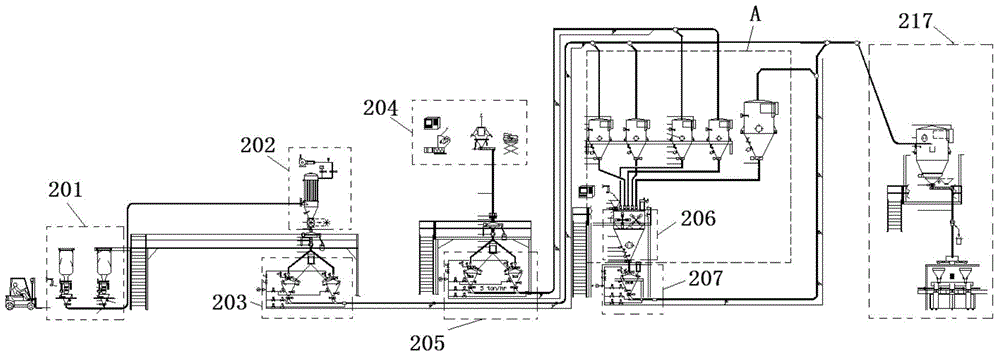

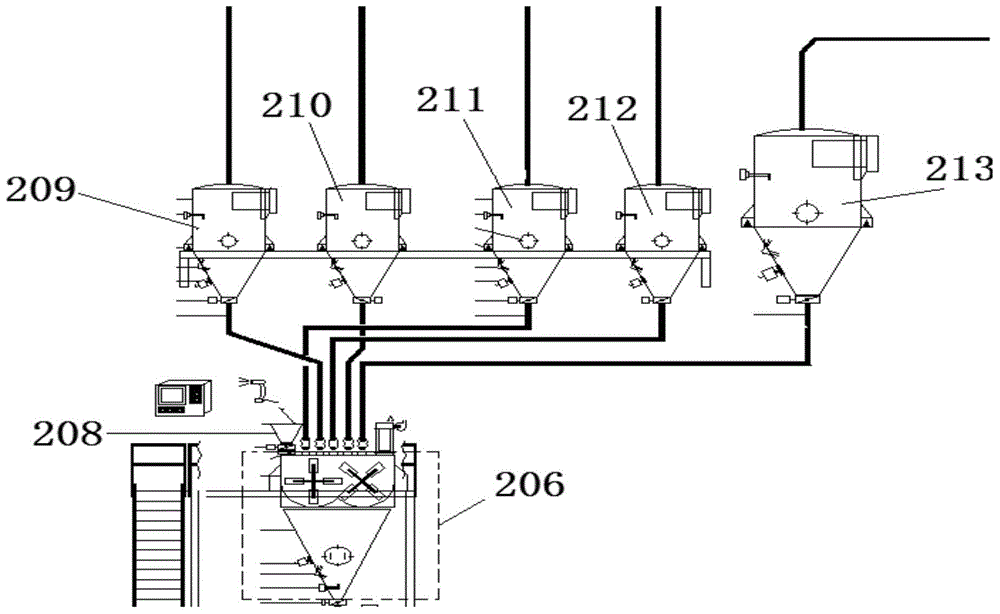

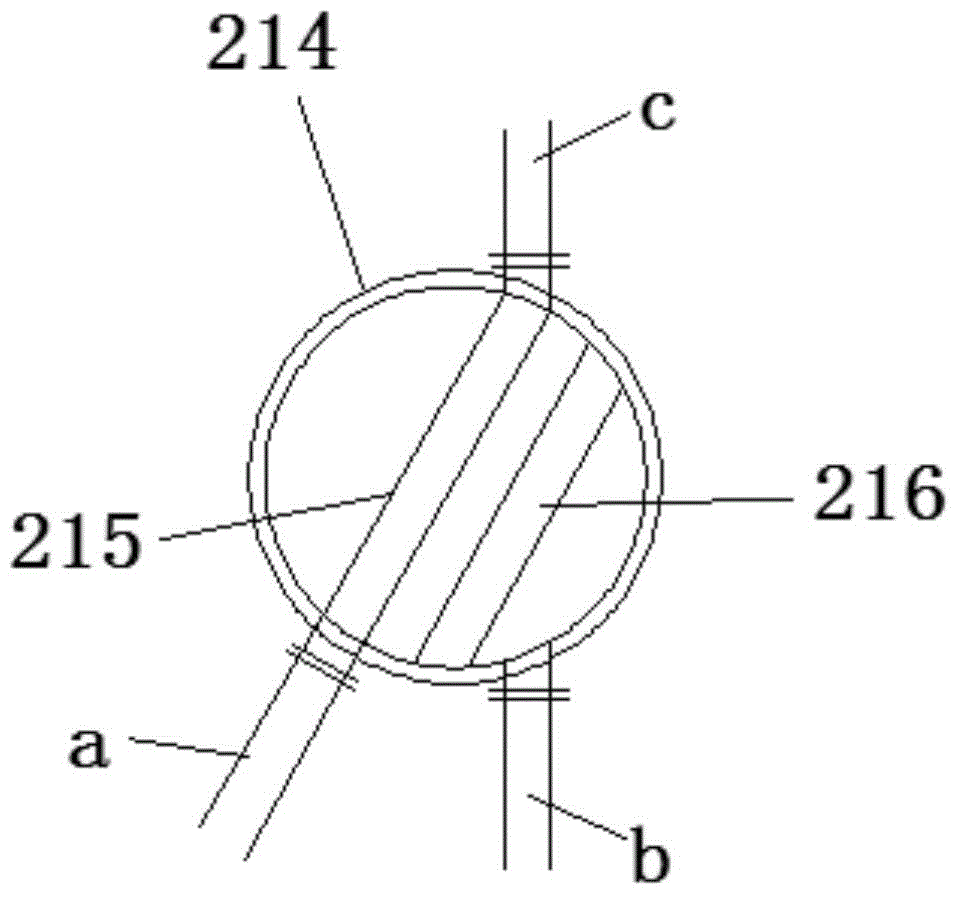

[0028] The specific embodiment of the present invention is described in conjunction with the accompanying drawings: the mixing equipment of the milk powder dry mixing section of the present invention includes a base powder pouring device 201, a main powder feeding device 204, a trace element feeding device 208, a buffer system, and a dry blending machine 206 , purpose powder bin 217, base powder air delivery system 203, main powder air delivery system 205, mixed powder material air delivery system 207 and conversion device, the buffer system includes the first base powder buffer tank 209, the second base powder buffer tank 210, the first main powder buffer tank 211, the second main powder buffer tank 212 and the semi-finished product buffer tank 213, the output end of the base powder pouring device 201 is connected to the base powder air delivery system 203, and the output end of the base powder air delivery system 203 is connected to the first A base powder buffer tank 209 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com