Railroad utilized unloading equipment by using hydraulic force to careen tracks

A track and hydraulic technology, which is applied in the field of railway hydraulic tilting track unloading equipment, can solve the problems of large floor area, many auxiliary facilities, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

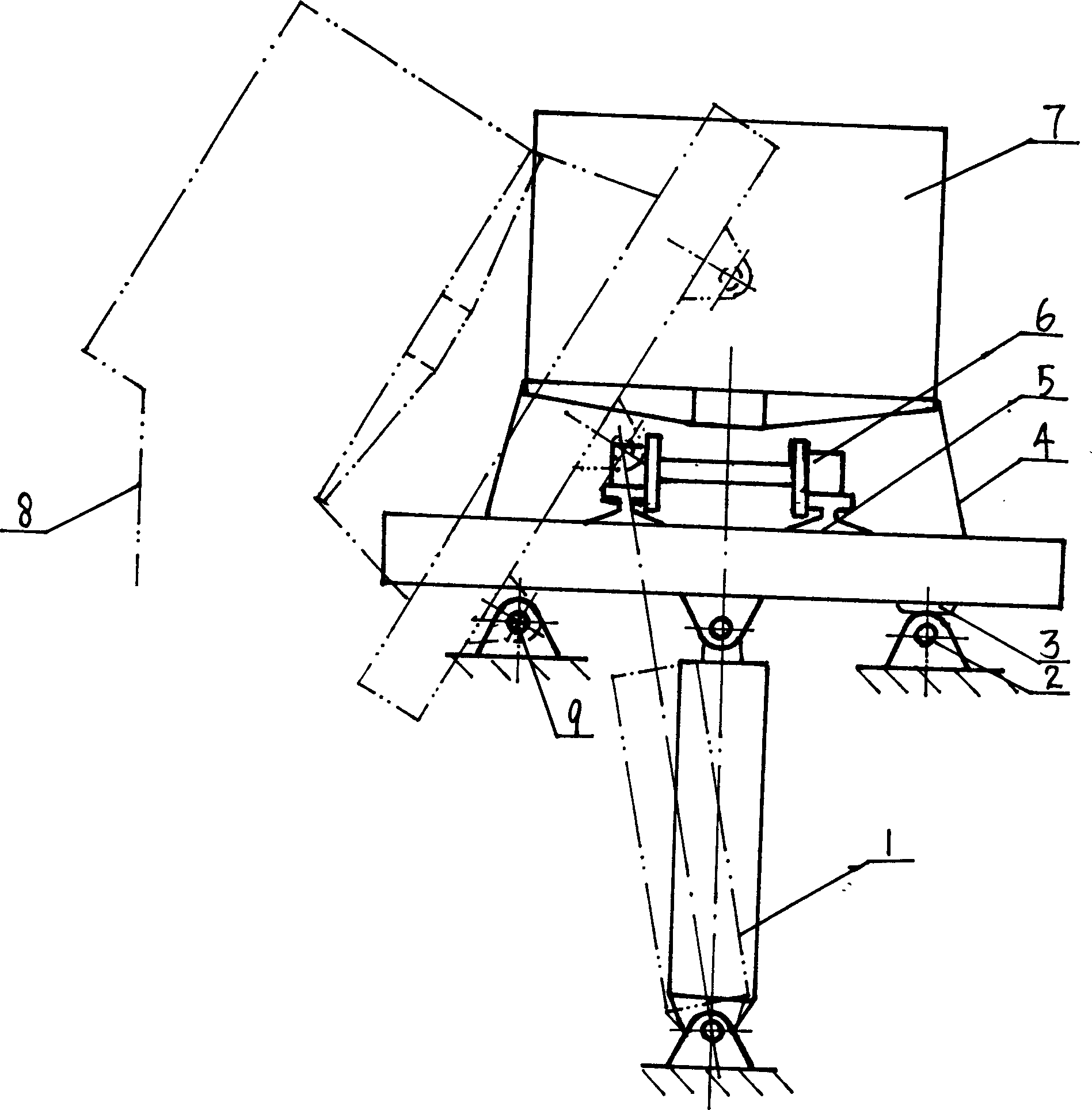

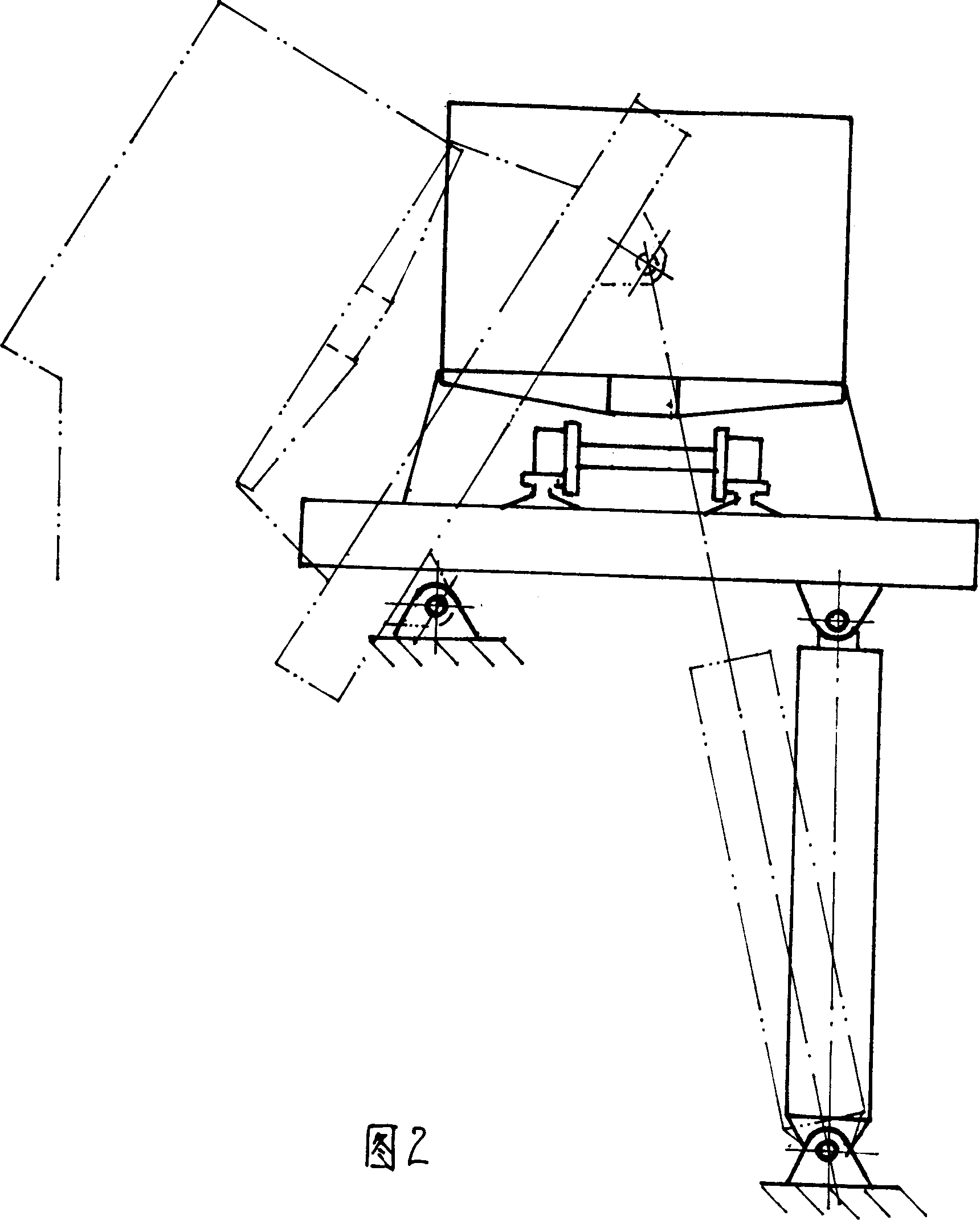

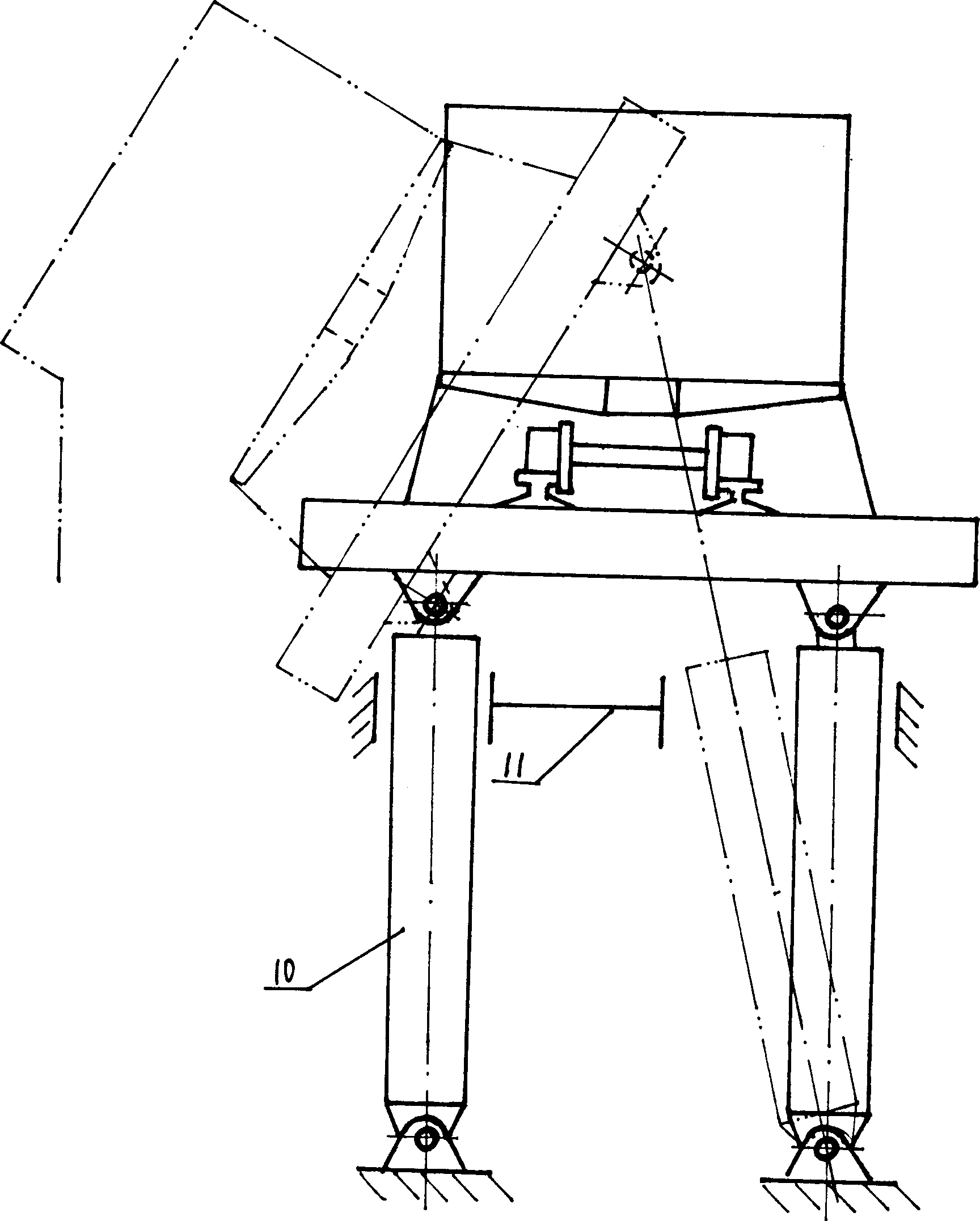

[0015] The present invention includes a hydraulic cylinder 1, a base 2, a bayonet pin 3, a safety fastening device 4, a track support 5, a wheel 6, a carriage 7, a baffle 8, a hinge shaft 9, an oil cylinder 10, a restricting device 11, and an ejection piston 12. Roller 13, ejector rod 14, track 15, booster frame 16, pillar 17.

[0016] The track support 5 of its track part is hinged with the base 2 on one side, and the track support 5 is connected with the lifting device that jacks up the track support 5 to make it rotate around the base 2. Safety fastening device 4.

[0017] The lifting device is provided with at least one ejected hydraulic cylinder 1 below the track support 5 , the hydraulic cylinder 1 is hinged to the track support 5 , and one end of the track support 5 is hinged to the base 2 .

[0018] Described hydraulic cylinder 1 is supported on the middle part of track support 5, and one end of track support 5 is hinged with base 2, as attached figure 1 As shown, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com